High-performance glaze

A high-performance, glaze technology, which is applied in the field of glaze preparation from inorganic materials, can solve the problems of high cost of electric porcelain and low first pass rate of electric porcelain, and achieve the effect of reducing production cost, high uniformity and improving yield value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following is further described in detail through specific implementation methods:

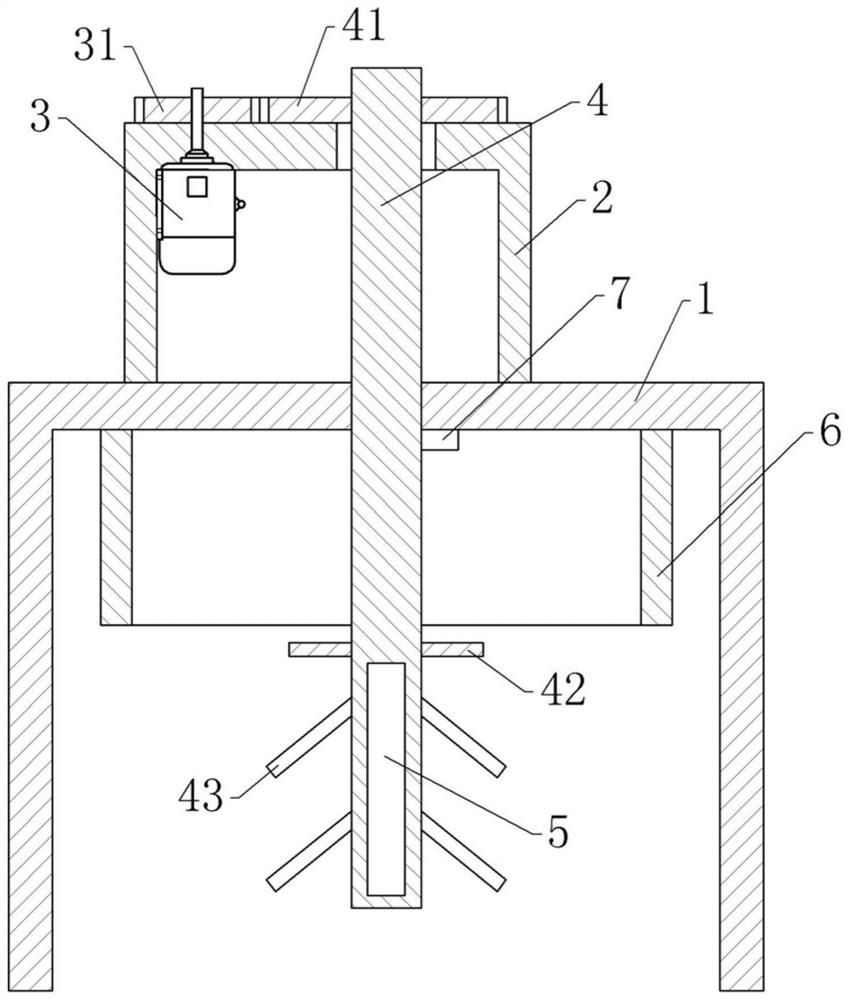

[0034] The reference signs in the drawings of the description include: support frame 1, mounting frame 2, forward and reverse motor 3, driving gear 31, rotating shaft 4, driven gear 41, rotating disc 42, stirring rod 43, electromagnet 5, magnet ring 6. Button 7.

[0035] The invention provides a high-performance glaze, which comprises high-potassium and low-sodium feldspar, high-sodium and low-potassium feldspar, ball clay, hard kaolin, calcined talc, limestone, quartz powder and sodium carboxymethylcellulose.

[0036] The high-potassium and low-sodium feldspar is selected from the high-potassium and low-sodium feldspar produced by Hunan Linxiang Hongfa Mineral Products Management Department. Its appearance is yellow or light yellow powder. When preparing a high-performance glaze, select a powder whose particle size is less than or equal to 0.063mm and the weight ratio exceeds 70% o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com