Anti-ferroelectric ceramic material and preparation method thereof

A ceramic material and antiferroelectric technology, which is applied in the field of antiferroelectric ceramic materials and its preparation, can solve the problems of large energy loss and achieve the effects of improved efficiency, high energy storage efficiency, and economical and practical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A method for preparing an antiferroelectric ceramic material, comprising:

[0026] (1) Select Pb with a purity greater than 99% 3 o 4 、BaCO 3 , La 2 o 3 , ZrO 2 , SnO 2 As a raw material for antiferroelectric ceramics;

[0027] (2) weigh according to chemical composition, add ball milling medium and carry out ball milling, discharging, drying;

[0028] (3) Calcining the dried powder in a muffle furnace at 800-900°C for 2-3 hours;

[0029] (4) The calcined powder is subjected to secondary ball milling, discharging, drying, adding PVA to granulate, and pressing it into a ceramic disc under a pressure of 6-8 MPa;

[0030] (5) Debinding the obtained ceramic green body in a muffle furnace, and keeping it warm at 500-600° C. for 5-10 hours;

[0031] (6) The ceramic green body after debinding is sintered at 1200-1350°C, the heating rate is controlled at 2-5°C / min, and the temperature is kept at the highest temperature for 2-5h, and after natural cooling to room temper...

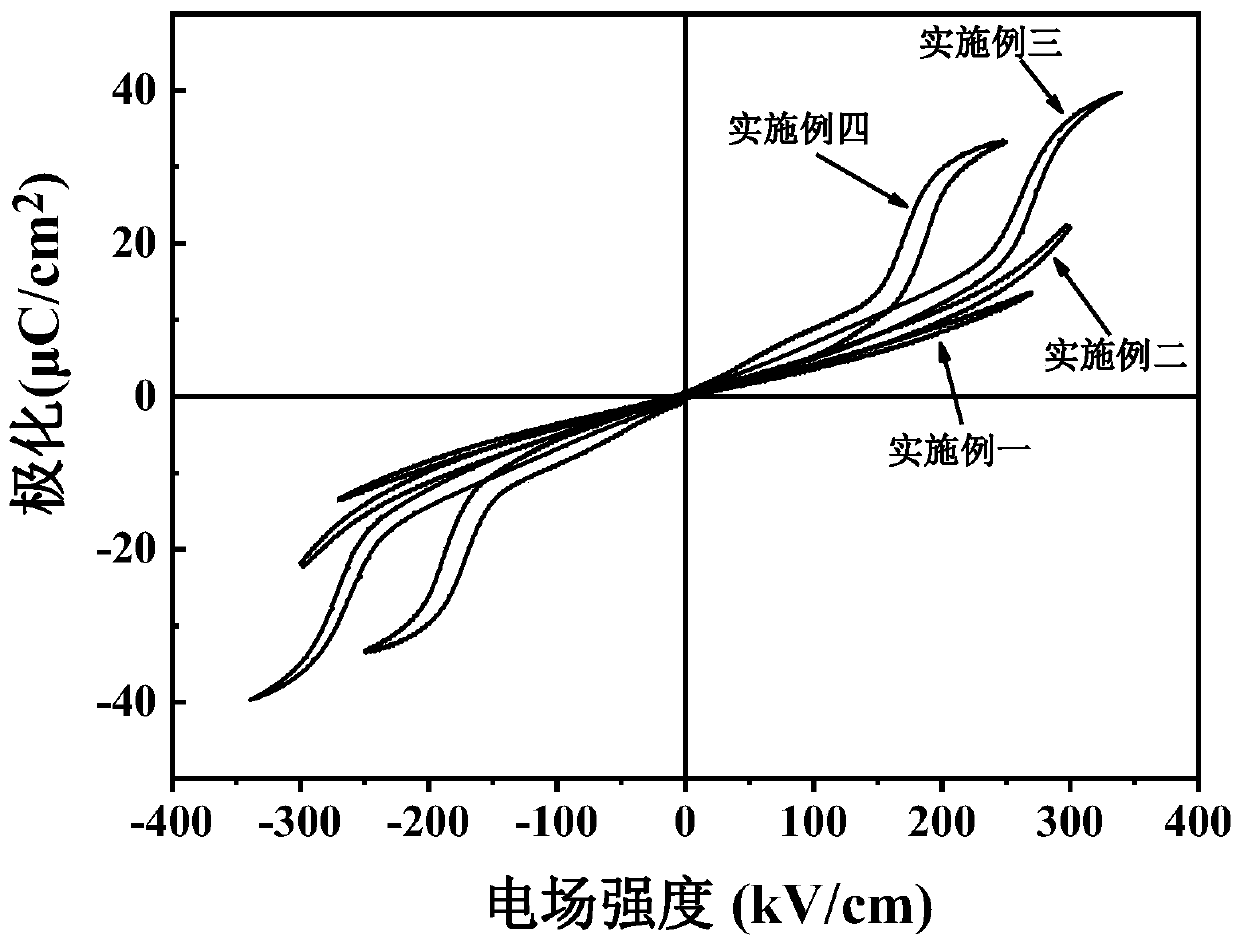

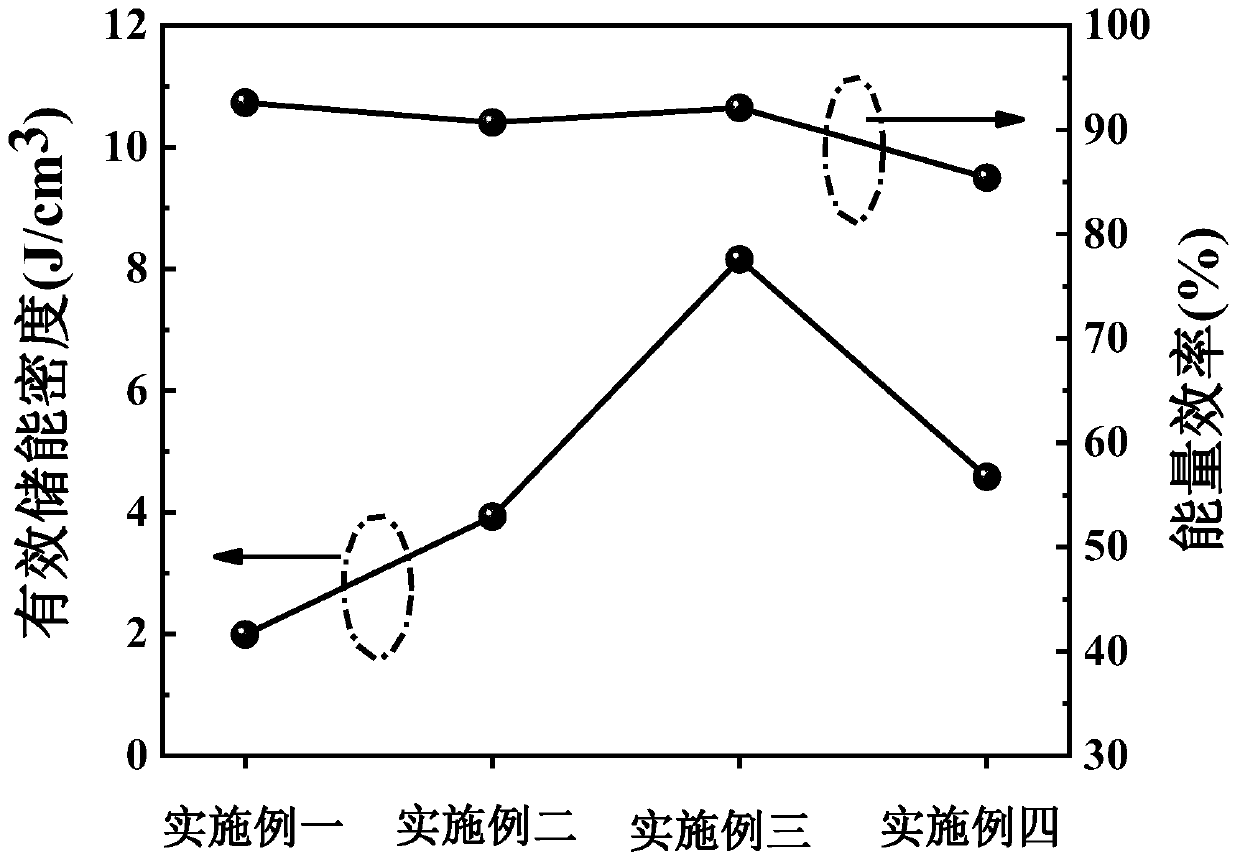

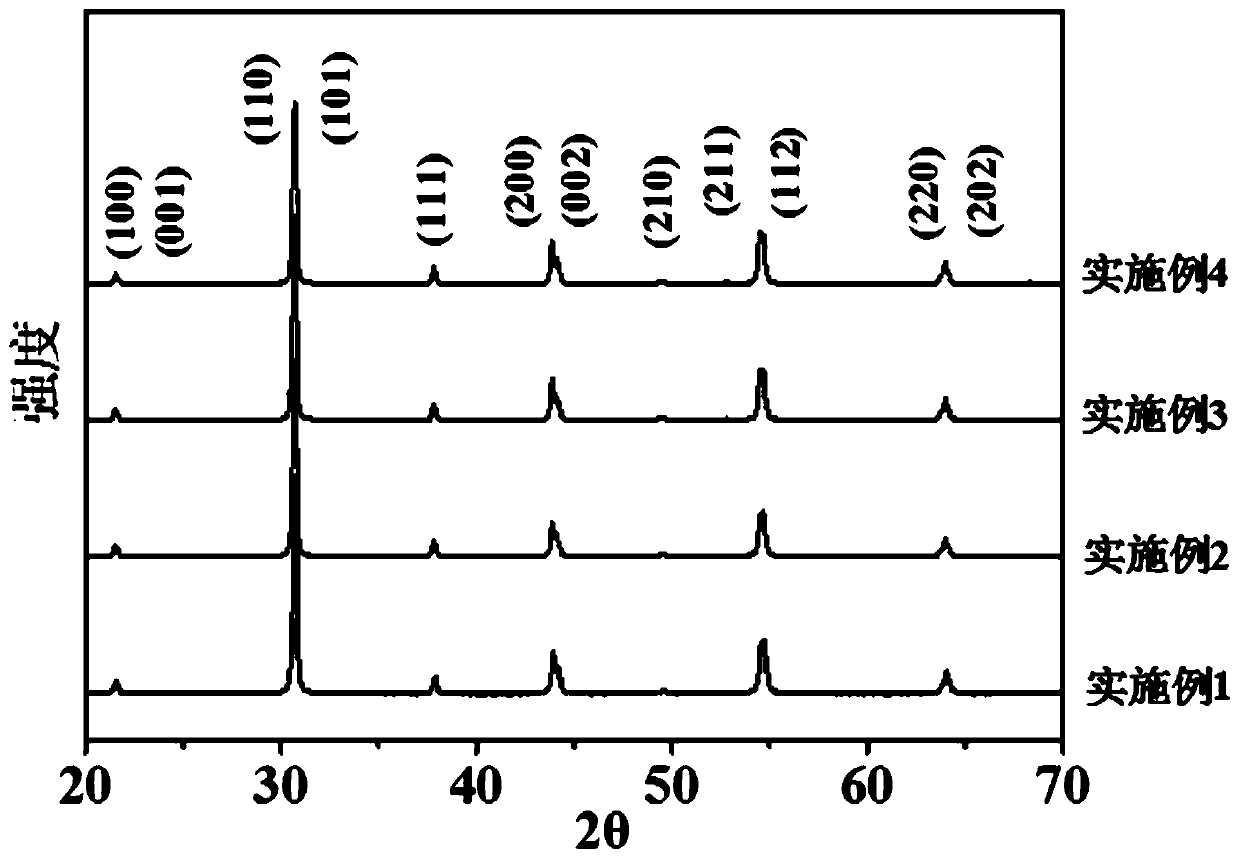

Embodiment 1

[0034] The chemical composition of antiferroelectric ceramics is (Pb 0.91 Ba 0.015 La 0.05 )(Zr 0.6 sn 0.4 )O 3 , including the following steps:

[0035] (1) Select Pb with a purity greater than 99% 3 o 4 、BaCO 3 , La 2 o 3 , ZrO 2 , SnO 2 As a raw material for antiferroelectric ceramics;

[0036] (2) weigh according to chemical composition, add ball milling medium and carry out ball milling, discharging, drying;

[0037] (3) Calcining the dried powder in a muffle furnace at 900°C for 3 hours;

[0038] (4) The calcined powder is subjected to secondary ball milling, discharged, dried, then added with PVA for granulation, and pressed into ceramic discs under a pressure of 8 MPa;

[0039] (5) Debinding the obtained ceramic green body in a muffle furnace, and keeping it warm at 600° C. for 10 hours;

[0040] (6) The ceramic green body after debinding is sintered at 1275°C, the heating rate is controlled at 2°C / min, and the temperature is kept at the highest temperat...

Embodiment 2

[0043] The chemical composition of antiferroelectric ceramics is (Pb 0.91 Ba 0.03 La 0.04 )(Zr 0.6 sn 0.2 )O 3 , including the following steps:

[0044] (1) Select Pb with a purity greater than 99% 3 o 4 、BaCO 3 , La 2 o 3 , ZrO 2 , SnO 2 As a raw material for antiferroelectric ceramics;

[0045] (2) weigh according to chemical composition, add ball milling medium and carry out ball milling, discharging, drying;

[0046] (3) Calcining the dried powder in a muffle furnace at 900°C for 3 hours;

[0047] (4) The calcined powder is subjected to secondary ball milling, discharged, dried, then added with PVA for granulation, and pressed into ceramic discs under a pressure of 8 MPa;

[0048] (5) Debinding the obtained ceramic green body in a muffle furnace, and keeping it warm at 600° C. for 10 hours;

[0049] (6) The ceramic green body after debinding is sintered at 1275°C, the heating rate is controlled at 2°C / min, and the temperature is kept at the highest temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com