Novel MnZn-doped ferrite material and preparation method thereof

A ferrite, a new type of technology, applied in the field of new MnZn ferrite ceramic materials and preparation, can solve the problems of high resistivity, low loss, etc., and achieve the effect of light weight, excellent comprehensive performance and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method includes the following process steps and contents:

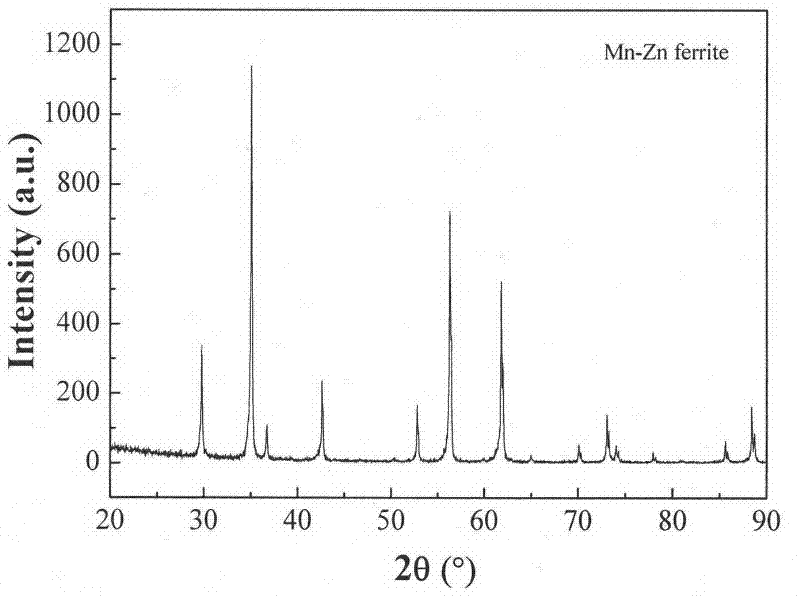

[0026] (1) Weigh the main material according to the design composition of the Mn-Zn ferrite soft magnetic material. The main material component and mole percentage are: Fe 2 O 3 45~55mol%, ZnO 22~26mol%, MnO 2 23-29 mol%.

[0027] (2) Mix the so-called main material powder, high-purity and high-wear-resistant zirconia grinding medium, and deionized water in a polyurethane ball mill tank, and grind and mix them on a high-energy ball mill.

[0028] (3) After drying the slurry, it is pre-fired at 800-950°C and kept for 0.5-5 hours.

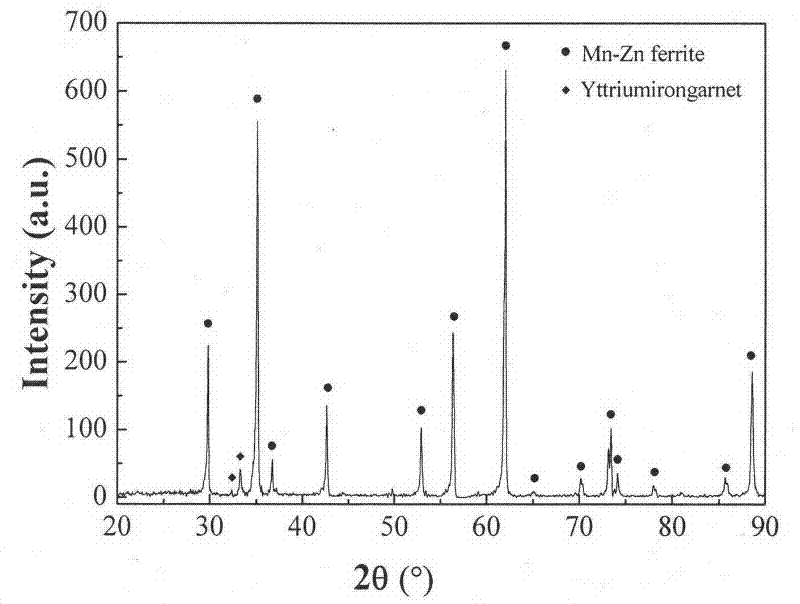

[0029] (4) Grind the pre-fired powder and add additives, the additives include Y 2 O 3 , Sb 2 O 3 , Cr 2 O 3 One or more of them, and each formula contains CaCO 3 , All additives are added in addition, respectively accounting for 0.05 to 5.0 mol% of the total amount of the main material; and 0.1 to 10 wt% of dispersant and adhesive are added respectively.

[0030] (5) Put the ...

Embodiment 1

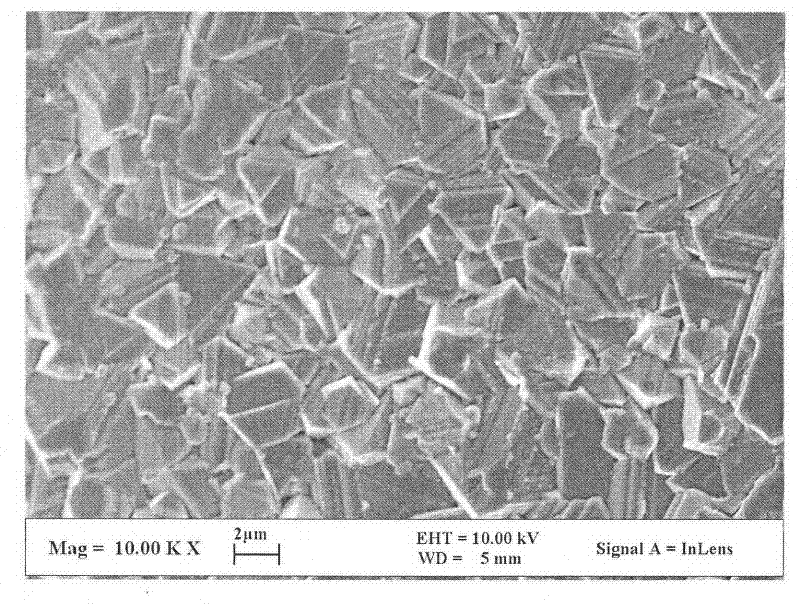

[0039] Example 1: The commercially available analytical pure Fe 2 O 3 , ZnO, MnO 2 Mix the materials in a molar ratio, where Fe 2 O 3 45mol%, ZnO 26mol%, MnO 2 29mol%. Wet high-energy ball milling is used, in which the mass ratio of mixed powder, zirconia ball and deionized water is 1:4:2, and ball milled in a polyurethane ball mill for 12 hours. The obtained slurry was placed in a drying box and dried in the air at 105° C. for 96 hours. After rough grinding, it was pre-fired at 950° C. for 0.5 hours. Add 5mol% Y according to the molar ratio 2 O 3 , 5mol% CaCO 3 , And add 10wt% polyvinyl alcohol and 10wt% Davon C. According to the mass ratio of 1:4:2, the powder: grinding ball: deionized water is put into the polyurethane ball milling tank, after 72 hours of ball milling on the ball mill, it is dried in the air and in a drying box at 150°C for 96 hours, and then ground After sieving, dry pressed into a disc or ring shape. In an electric furnace, the temperature is increased...

Embodiment 2

[0041] Example 2: The commercially available analytical pure Fe 2 O 3 , ZnO, MnO 2 Mix the materials in a molar ratio, where Fe 2 O 3 55mol%, ZnO 22mol%, MnO 2 23mol%. Wet high-energy ball milling is used, in which the mass ratio of mixed powder, zirconia ball and deionized water is 1:4:2, and ball milled in a polyurethane ball mill for 72 hours. The obtained slurry was placed in a drying box and dried in a vacuum drying box at 40°C for 12 hours, and after rough grinding, it was pre-fired at 800°C for 5 hours. Add 0.05mol% Sb according to the molar ratio 2 O 3 、0.05mol%CaCO 3 , And add 0.1wt% polyvinyl alcohol and 0.1wt% Davon C. According to the mass ratio of 1:4:2, the powder: grinding ball: deionized water is put into the polyurethane ball mill tank, after 12 hours of ball milling on the ball mill, it is dried in a vacuum drying oven at 40°C for 96 hours. After sieving, dry pressed into disc or ring shape. In an electric furnace, the temperature is raised according to a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com