Opal glaze for electroceramics and glazing process thereof

A technology of milky white glaze and electric porcelain, applied in the field of electric porcelain, can solve the problems of efficiency and reputation impact of large milky white glaze products, and achieve the effect of smooth and flat surface and improved surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

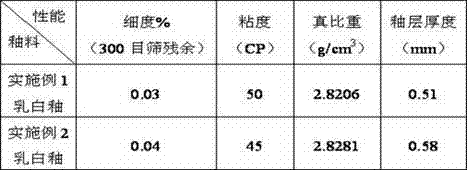

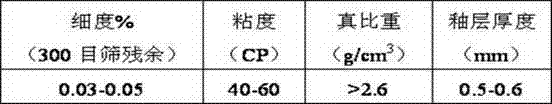

Embodiment 1

[0020] Embodiment 1: The glazed product is an integrally formed casing

[0021] Product name: 56760 Voltage level: 220kV

[0022] Product height: 2.5 meters User: American HVB Company

[0023] 1. Preparation of milky white glaze:

[0024] Get the following ingredients and their percentages by weight: Datong sand 8%; talcum powder 8%; limestone 1.1%; Faku clay 5.4%; white dry stone 9.99%; Zirconium acid 11.99%; SP-100 dispersant 0.06%.

[0025] 2. Glazing:

[0026] ① Dip glaze

[0027] Take the milky white glaze prepared above, control the Baumé degree at 49Be, and dip the integrally formed casing, the dipping time is controlled at 15 seconds, and the measured average value of the thickness of the glaze layer is 0.37mm;

[0028] ②Primary and secondary glaze spraying

[0029] Take the milky white glaze prepared above, and the Baume degree is controlled at 54Be;

[0030] a. One-time glaze spraying: Spray milky white glaze once from top to bottom on the overall forming slee...

Embodiment 2

[0034] Example 2: Inorganic bonding porcelain sleeve

[0035] Product name: 55800 Voltage level: 550kV

[0036] Product height: 5 meters User: Furukawa Corporation

[0037] 1. Preparation of milky white glaze:

[0038] Take the following ingredients and their weight percentages: Datong sand 7.09%; talcum powder 8.19%; limestone 1.82%; Faku clay 6.39%; white dry stone 10.99%; Zirconium acid 12.29%; SP-100 dispersant 0.08%.

[0039] 2. Glazing:

[0040] ① Dip glaze

[0041] Take the milky white glaze prepared above, control the Baumé degree at 51Be, and dip the inorganic bonding porcelain sleeve. The dipping time is controlled at 20 seconds, and the measured average value of the thickness of the glaze layer is 0.42mm;

[0042] ②Primary and secondary glaze spraying

[0043] Take the milky white glaze prepared above, and the Baume degree is controlled at 55Be;

[0044] a. One-time glaze spraying: Spray milky white glaze from top to bottom on the inorganic bonded porcelain s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com