Electro ceramic coated aluminum transmission components

A technology of electronic ceramics and components, which can be used in brake components, components with teeth, gear transmission mechanisms, etc., and can solve problems such as unacceptable service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following description is merely exemplary in nature and is not intended to limit the disclosure, application, or uses.

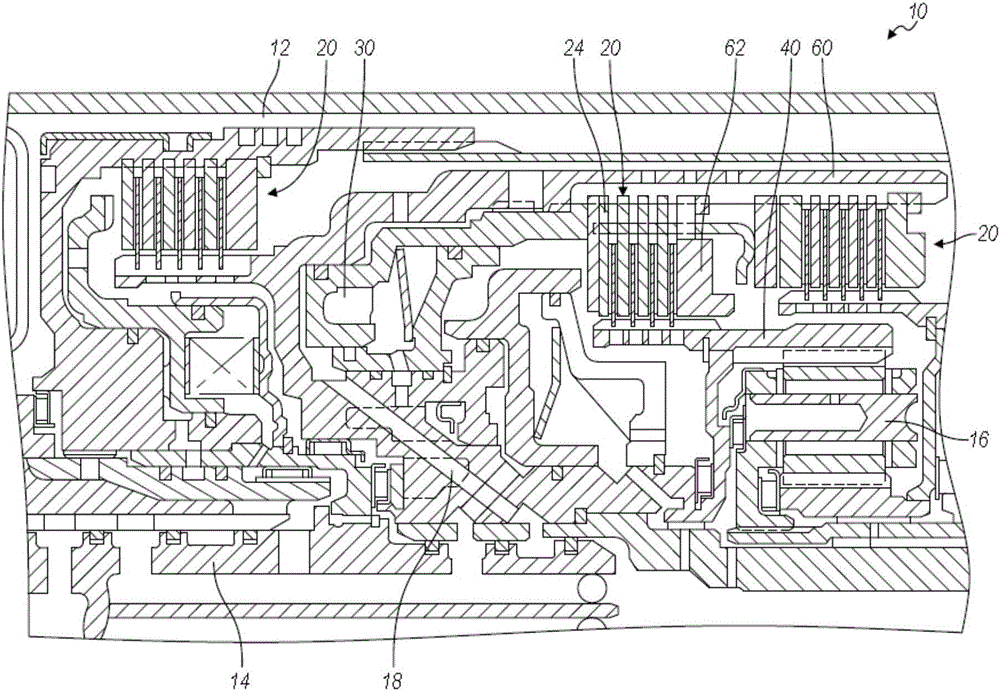

[0037] see figure 1 , shows a portion of a motor vehicle automatic transmission and is generally indicated by reference numeral 10 . The automatic transmission 10 includes a housing 12 that mounts, supports, positions and protects components such as shafts and quills 14, a plurality of planetary gear assemblies 16 (one of which is in figure 1 shown in ), fluid passage 18 and a plurality of friction clutch pack assemblies 20.

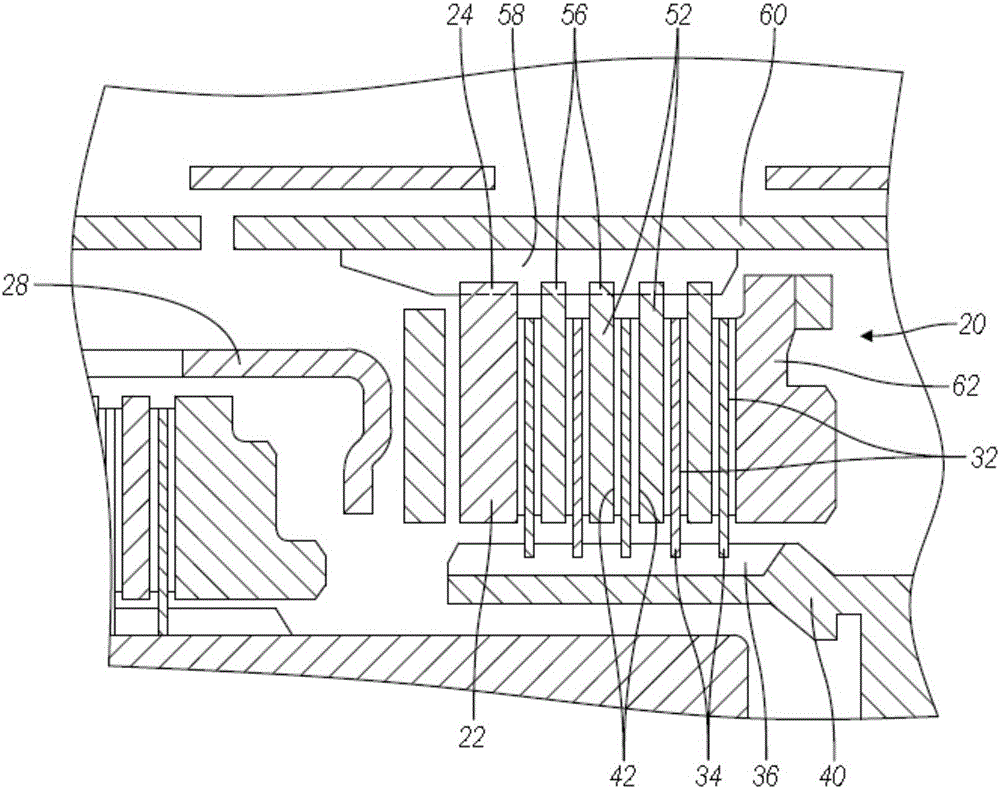

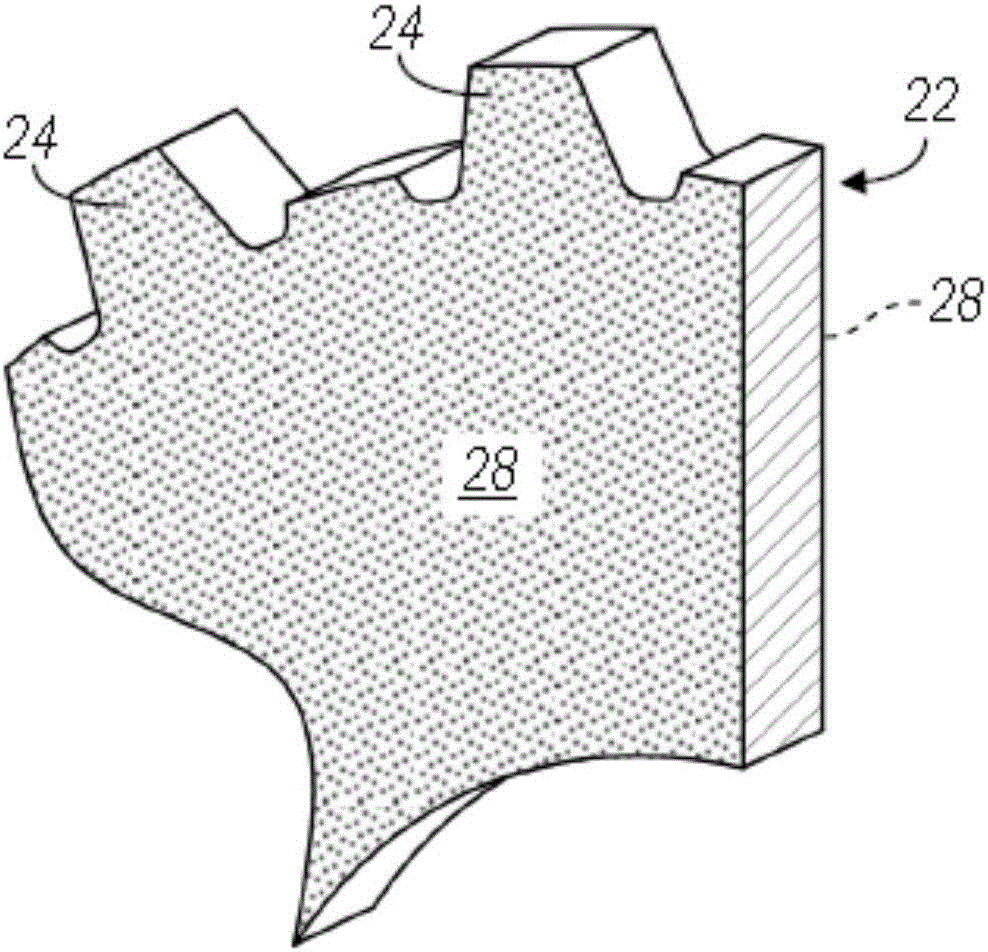

[0038] Now refer to figure 1 with figure 2 , the friction clutch pack assembly 20 includes an effect plate 22 having outer splines 24 disposed on its periphery that engage a plurality of inner splines 58 in an outer housing 60 to follow it rotate. The action plate 22 is actuated and axially translated by means of a linkage or member 28 driven by a hydraulic operator or brake 30 . The friction clutch pack assembly 20 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com