Flaky alpha-alumina crystals with large aspect ratio and a preparation method of the same

An alumina and flake technology, which is applied in the field of large aspect ratio flake α-alumina crystal and its preparation, can solve the problems of low aspect ratio, inability to display the excellent characteristics of pearlescent pigment matrix, large flake crystals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

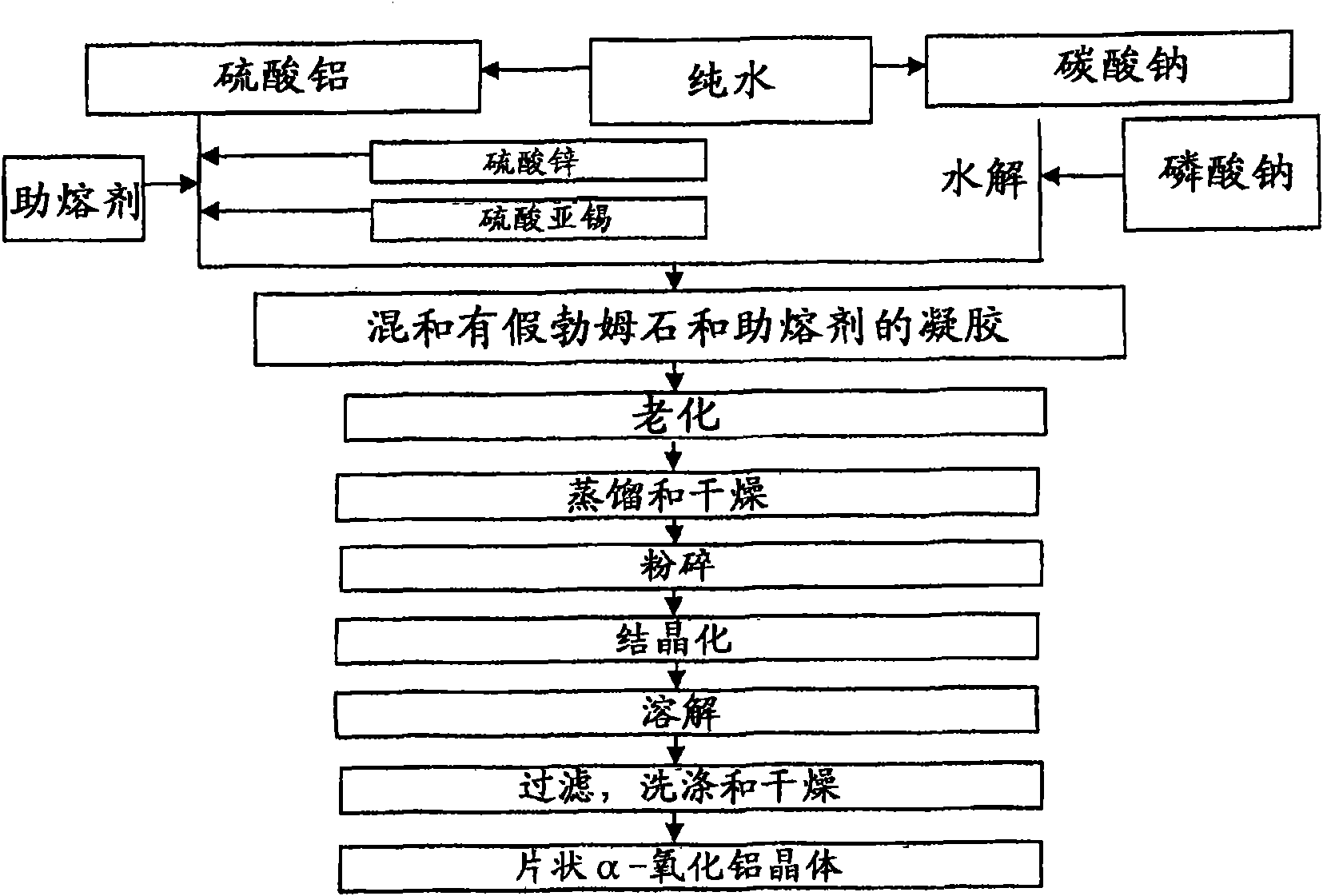

[0020] Further, the present invention relates to a method for preparing flaky α-alumina crystals, comprising:

[0021] (a) Prepare an aqueous metal precursor solution, which is obtained by mixing an aqueous aluminum precursor solution containing a water-soluble flux with an aqueous precursor solution containing 0.05-5 parts by weight of a zinc precursor and 0.01-0.5 parts by weight of a tin precursor, wherein the weight The parts are relative to 100 parts by weight of the aluminum precursor;

[0022] (b) titrate the aqueous metal precursor solution with a sodium salt solution to adjust the pH to 6.0-7.5, and perform hydrolysis to prepare a mixed gel;

[0023] (c) pretreating the hybrid gel by aging the hybrid gel at 60-100° C. for 5-30 hours, and drying the aged hybrid gel;

[0024] (d) drying the pretreated mixed gel at 60-200° C. for 5-30 hours;

[0025] (e) crystallizing the dried mixed gel at 850-1300° C. for 1-8 hours to prepare a cake mixed with flaky α-alumina crystal...

Embodiment 1

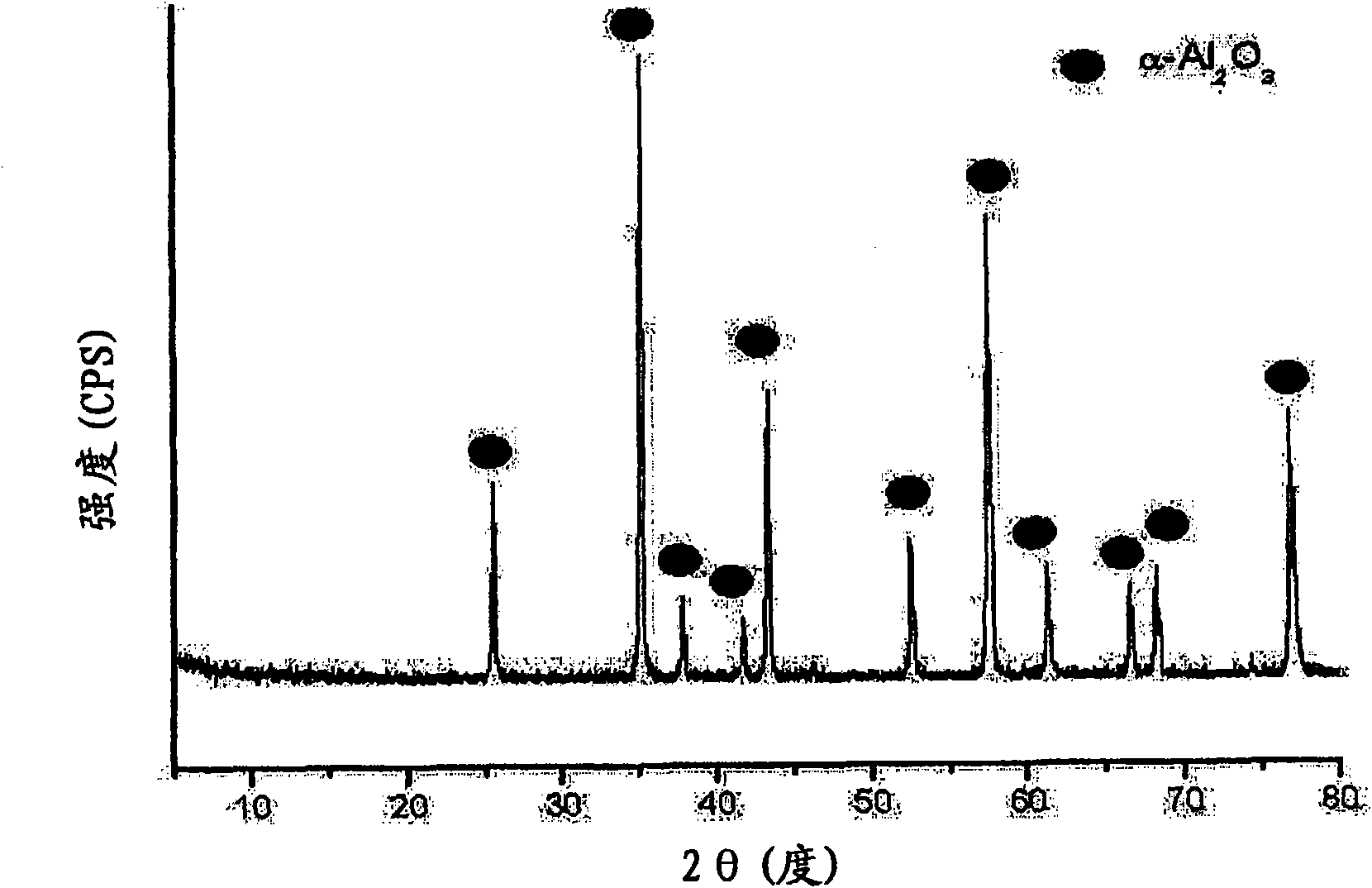

[0056] By mixing 670 g of aluminum sulfate (Al 2 (SO 4 ) 3 18H 2 O), 345g sodium sulfate (Na 2 SO 4 ), 280g potassium sulfate (K 2 SO 4 ), 4.8g 34% zinc sulfate (ZnSO 4 ·7H 2 O) aqueous solution and 1.0 g of 17% zinc sulfate (ZnSO 4 ·7H 2 O) Aqueous solution to prepare a homogeneous mixed solution. By dissolving 324g of sodium carbonate (Na 2 CO 3 ) and 2.7g sodium phosphate ((NaPO 3 ) 6 ) to prepare an alkaline solution. While stirring, the aluminum sulfate mixed solution (65° C.) was titrated with an alkali solution at a rate of 25 ml / min to adjust the final pH to 6.8 to prepare a gel mixed with pseudoboehmite and flux. The mixed silica gel was aged at 90°C for 20 hours, vacuum distilled at 60°C, and dried at 110°C for 20 hours. Flaky α-alumina crystals were prepared by pulverizing the dried mixed gel to less than about 5 mm, followed by crystallization in an alumina crucible (2 L) at 1200° C. for 7 hours. The flux was separated from the flaky α-alumina crys...

Embodiment 2

[0059] Transparent flaky α-alumina crystals were prepared as in Example 1 except that 0.5 g of 17% stannous sulfate was used.

[0060] The prepared flaky α-alumina crystals were confirmed to have an average particle thickness of 0.2 μm and an average particle size of 32.8 μm. Atomic analysis showed that it contained 0.4 parts by weight of zinc oxide and 0.04 parts by weight of tin oxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com