Rapid preparation method and application of core-shell spherical magnetic mesoporous silica nanocomposites

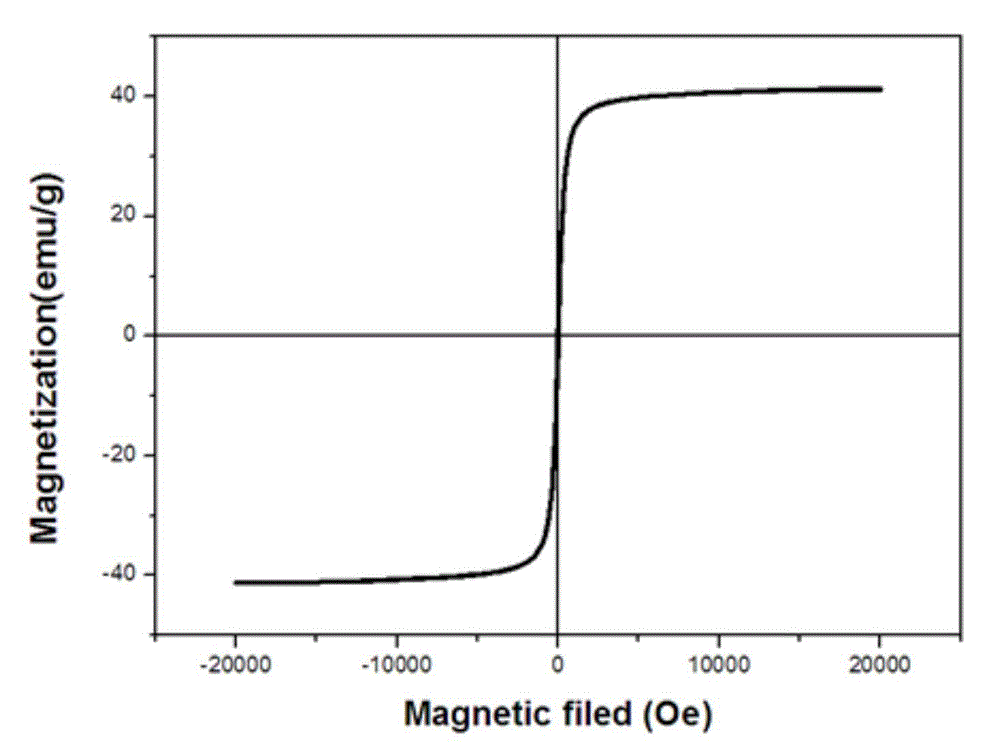

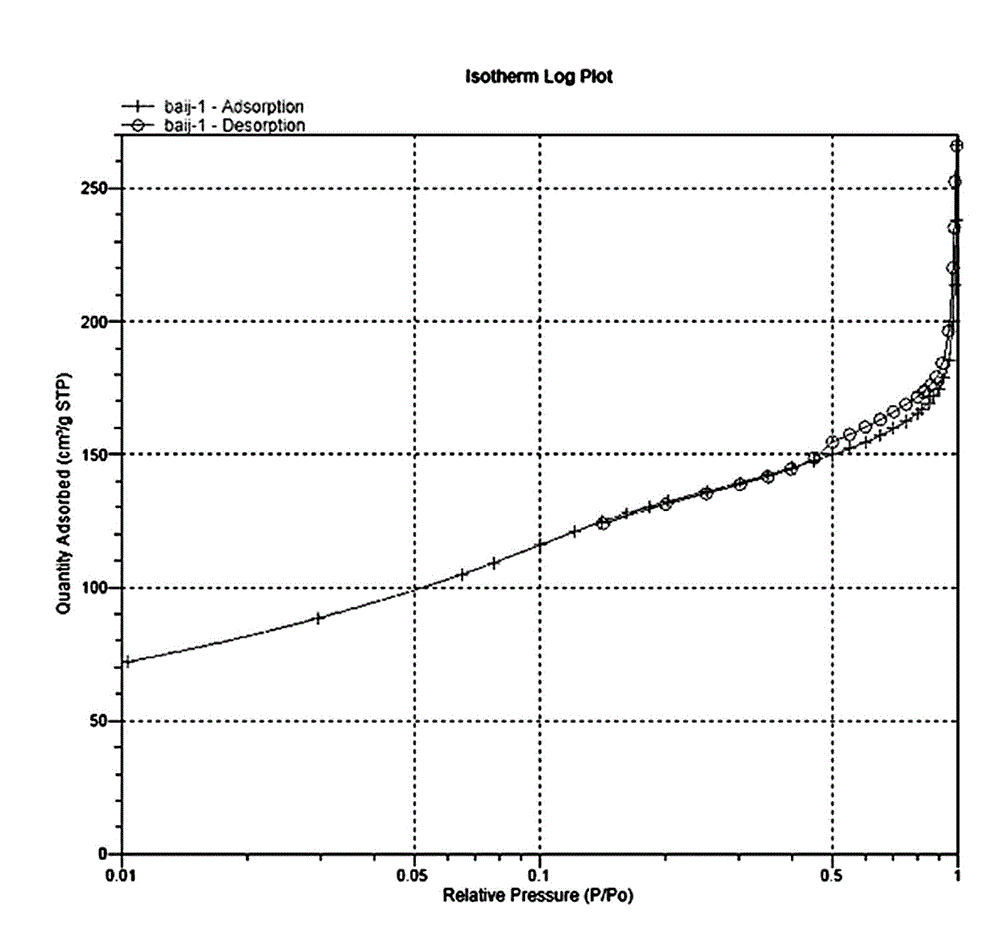

A nanocomposite material, mesoporous silica technology, applied in the direction of silica, silicon oxide, iron oxide, etc., can solve the problem of difficult control of particle shape, size uniformity, dispersion, and size uniformity of magnetic nanoparticles. Controlling, difficult to achieve highly dispersed nanoparticles and other problems, to achieve the effect of enhancing the effect of nuclear magnetic imaging, large drug loading capacity, and improving the effect of diagnosis and treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

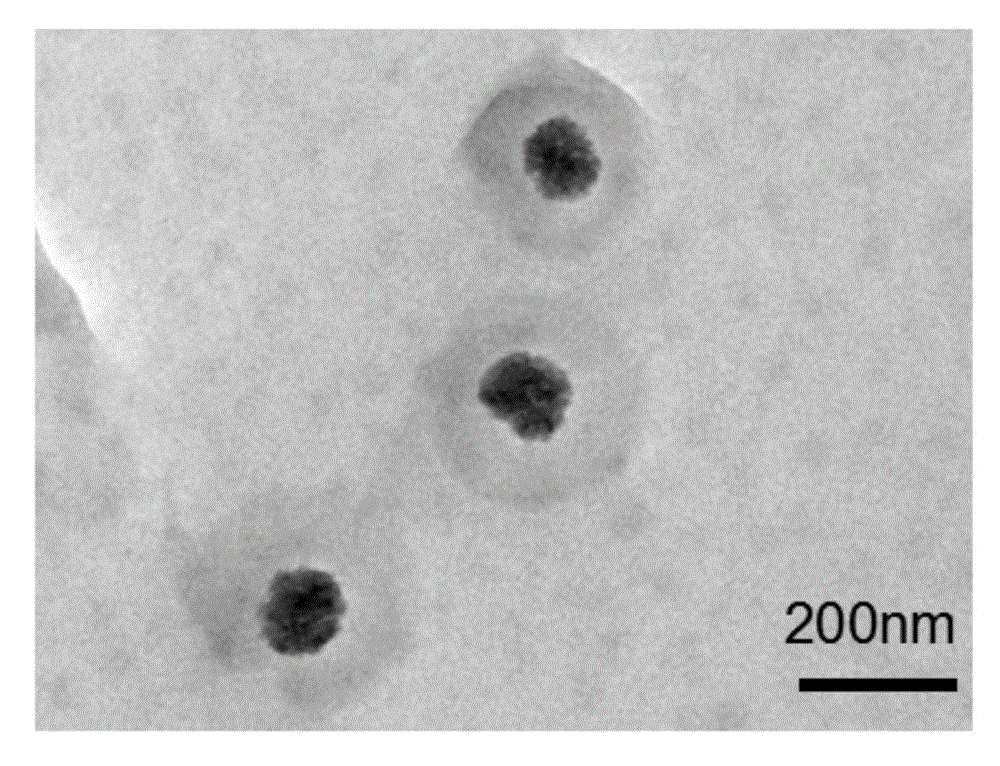

[0036] Example 1: Preparation of core-shell spherical magnetic mesoporous silica nanocomposites

[0037] In 34mL of diethylene glycol (DEG) solution, add 0.576gPAA and 0.13gFeCl3, under the protection of nitrogen, stir and heat to 250 ° C, after 20 minutes, add 2.8 mL of 80 ° C sodium hydroxide (NaOH) in diethylene glycol solution (0.1 g / mL), stirred and reacted for 1 hour, the reaction product was magnetically separated, washed with water, and dried to obtain spherical magnetic ferrite nanoparticles (Fe 3 o 4 ). Weigh 10mgFe 3 o 4 Disperse in deionized water, add 100mg CTAB, add 0.4mL ammonia water after ultrasonication for 40 minutes, stir and heat to 40°C, slowly add 10μLTEOS dropwise, stir and react for 20 minutes; separate and purify the reaction product to obtain core-shell spherical magnetic mesoporous silica nanocomposites. It was dispersed in 100mL of 0.5% ammonium nitrate ethanol solution, stirred and heated to reflux three times to remove CTAB. A core-shell sphe...

Embodiment 2

[0038] Example 2: Preparation of core-shell spherical magnetic mesoporous silica nanocomposites

[0039] In 34 mL of diethylene glycol (DEG) solution, add 0.576 g of PAA and 0.13 g of FeCl 3 , stirred and heated to 250°C under the protection of nitrogen, after 20 minutes, 2.8mL of 80°C sodium hydroxide (NaOH) diethylene glycol solution (0.1g / mL) was added, and the reaction product was magnetically separated after stirring for 1 hour. Washed with water and dried to prepare spherical magnetic ferrite nanoparticles (Fe 3 o 4 ). Weigh 10mgFe 3 o 4 Disperse in deionized water, add 150mg CTAB, add 0.4mL ammonia water after ultrasonication for 40 minutes, stir and heat to 40°C, slowly add 15μLTEOS dropwise, stir and react for 20 minutes; separate and purify the reaction product to obtain core-shell spherical magnetic mesoporous silica nanocomposites. It was dispersed in 100mL of 0.5% ammonium nitrate ethanol solution, stirred and heated to reflux three times to remove CTAB. A ...

Embodiment 3

[0040] Example 3: Preparation of core-shell spherical magnetic mesoporous silica nanocomposites

[0041] In 34mL of diethylene glycol (DEG) solution, add 0.576gPAA and 0.13gFeCl3, under the protection of nitrogen, stir and heat to 250 ° C, after 20 minutes, add 2.8 mL of 80 ° C sodium hydroxide (NaOH) in diethylene glycol solution (0.1 g / mL), after stirring for 1 hour, the reaction product was magnetically separated, washed with water, and dried to prepare spherical magnetic ferrite nanoparticles (Fe 3 o 4 ). Weigh 10mgFe 3 o 4 Disperse in deionized water, add 200mg CTAB, add 0.5mL ammonia water after ultrasonication for 40 minutes, stir and heat to 40°C, slowly add 20μLTEOS dropwise, stir and react for 20 minutes; separate and purify the reaction product to obtain core-shell spherical magnetic mesoporous silica nanocomposites. It was dispersed in 100mL of 0.5% ammonium nitrate ethanol solution, stirred and heated to reflux three times to remove CTAB. A core-shell spheri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com