Method for preparing polymer/SiO2 nano composite material

A nanocomposite material and polymer technology, which is applied in the field of preparation of polymer/silica nanocomposite materials, can solve the problems of complex process, high cost and unsatisfactory effect, and achieve simple process, suitable for quantitative production, cost low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention provides a polymer / SiO 2 Preparation method of nanocomposite material, polymer and functionalized SiO 2 Preparation of Polymer / SiO by Solution Blending or Melt Blending of Nanoparticles 2 Nanocomposites, polymers and functionalized SiO 2 The mass ratio of nanoparticles is: 100: 1~6 (preferably 100: 1~3);

[0030] Among them, functionalized SiO 2 Nanoparticles for the polymer surface modified SiO 2 Nanoparticles, its preparation method comprises the steps:

[0031] a will nano-SiO 2 Blend with the polymer in a solvent to dissolve the polymer completely, then add a precipitant to precipitate a precipitate, and finally filter and dry the precipitate to obtain the polymer / nano-SiO 2 Premix; among them, the polymer and nano-SiO 2 The mass ratio is: 100:10~20;

[0032] b Melt blending the premix prepared in step a above the melting point of the polymer and below the decomposition temperature for 5 to 30 minutes to obtain the polymer / nanometer SiO...

Embodiment 1

[0047] Example 1PC / functionalized nano-SiO 2 Preparation of composite materials

[0048] 1. Functionalized nano-SiO 2 preparation of

[0049] In this embodiment, the preparation and centrifugation method of the premix are the same as in Comparative Example 1, except that the premix (20 g of it) is melt-blended on a twin-screw extruder for 10 min, wherein the screw speed is 30 rpm and the melting temperature 250°C, granulate after extrusion; the functionalized nanoparticles obtained in this example are referred to as SiO 2 -10.

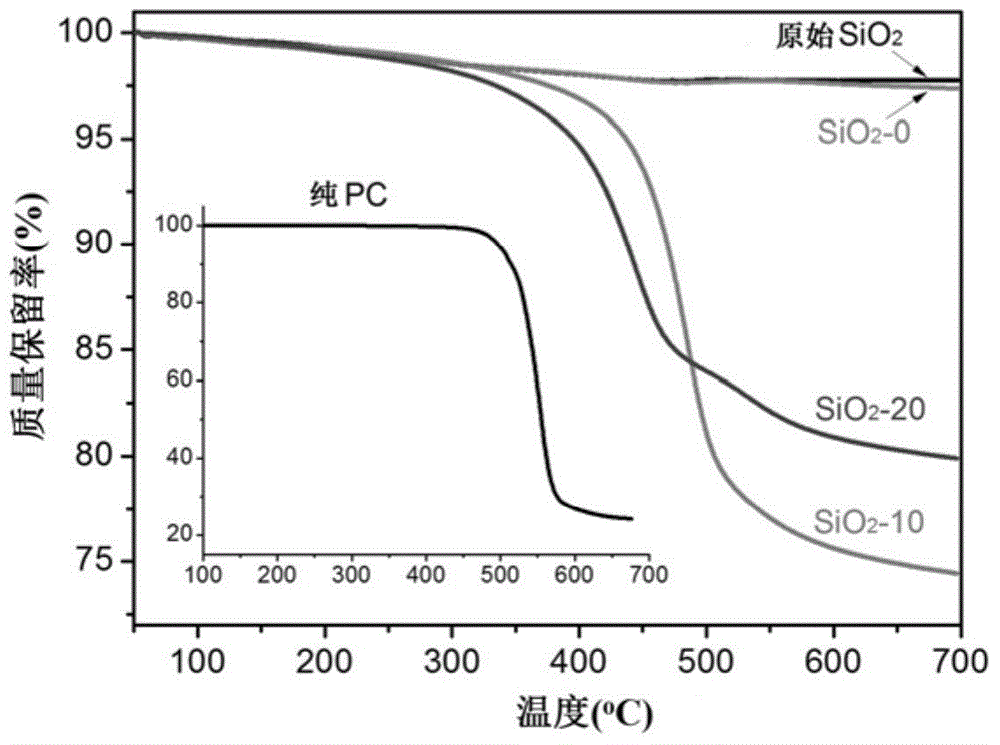

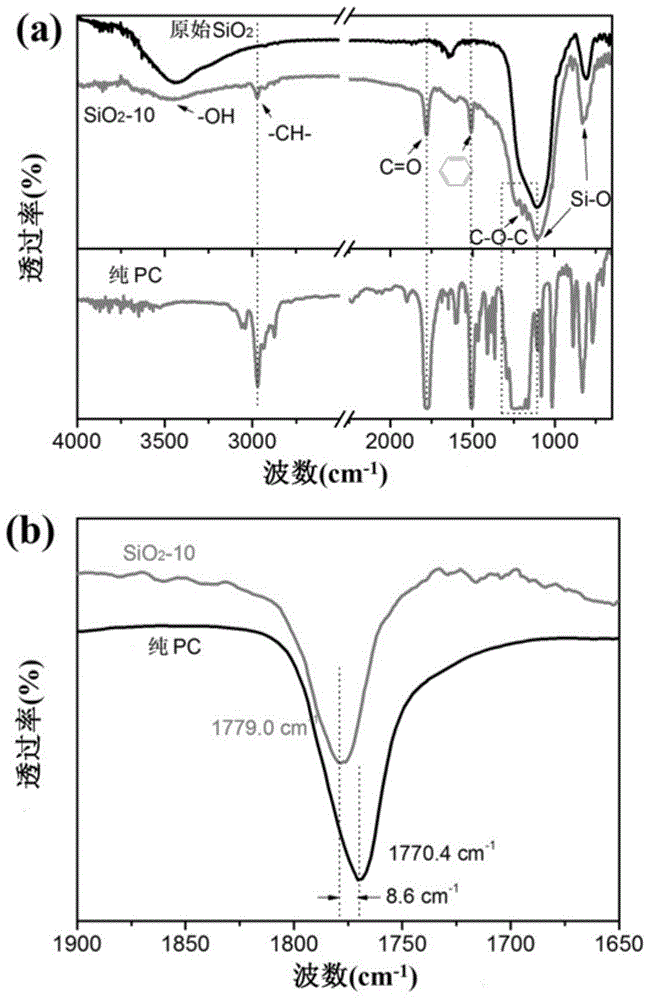

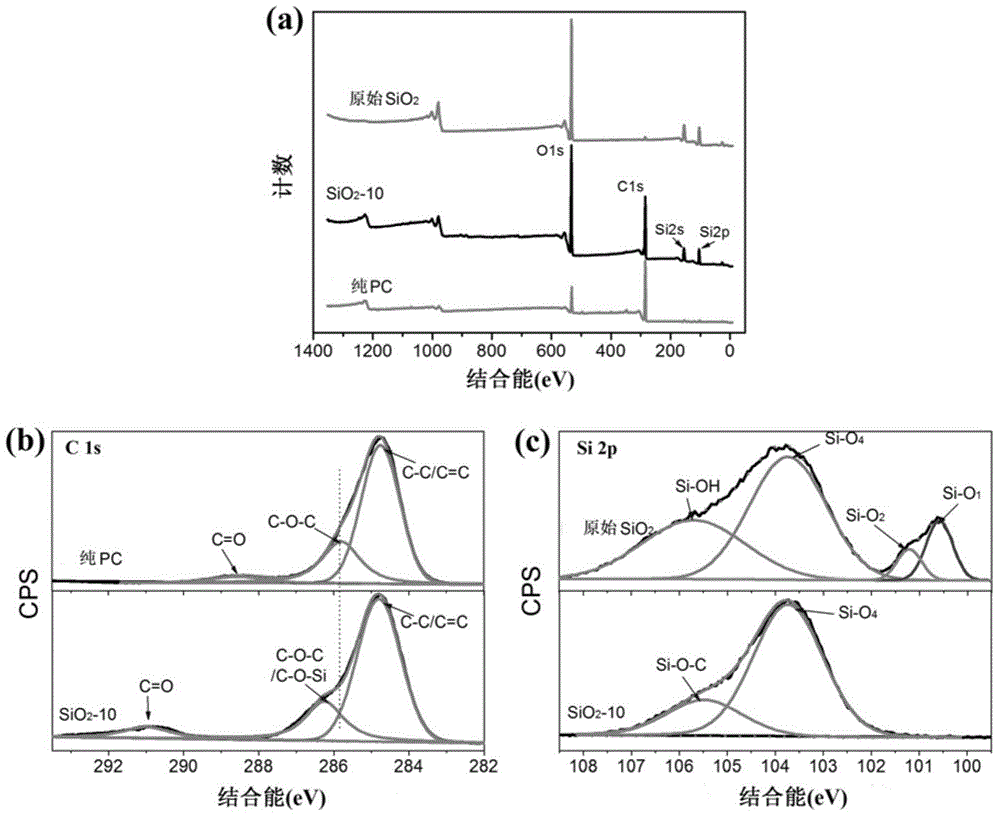

[0050] The resulting SiO 2 -10 carries out thermogravimetric experiment (method is with comparative example 1), and result is as follows figure 1 shown by figure 1 It can be seen that SiO 2 TGA curve of -10 compared to pristine SiO 2 There are significant differences, and there is an obvious mass loss in the range of 350-550 ° C, indicating that the physical and chemical effects in the process of melt blending for 10 min promote the grafting of...

Embodiment 2

[0057] Embodiment 2PC / functionalized nano-SiO 2 Preparation of composite materials

[0058] 1. Functionalized nano-SiO 2 preparation of

[0059] In this embodiment, except that the melt blending time is 20min, other operations are the same as in Example 1, and the obtained functionalized nanoparticles are referred to as SiO 2 -20, the resulting composite material is PCS20.

[0060] The resulting SiO 2 -20 carries out thermogravimetric experiment (method is with comparative example 1), and result is as follows figure 1 shown by figure 1 It can be seen that compared with pristine SiO 2 , SiO 2 The thermogravimetric curve of -20 shows that it has a more obvious mass loss in the range of 350-550 ° C; however, SiO 2 The thermal degradation temperature and mass loss of -20 are lower than that of SiO 2 -10, indicating that too long melt blending time is not conducive to the increase of polymer grafting rate, mainly because longer melt blending time will lead to an increase i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com