Anti-static coating material, preparation method thereof, anti-static coating and forming method thereof

A coating material and anti-static technology, applied in conductive coatings, coatings, devices for coating liquid on the surface, etc., can solve problems such as poor mechanical wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

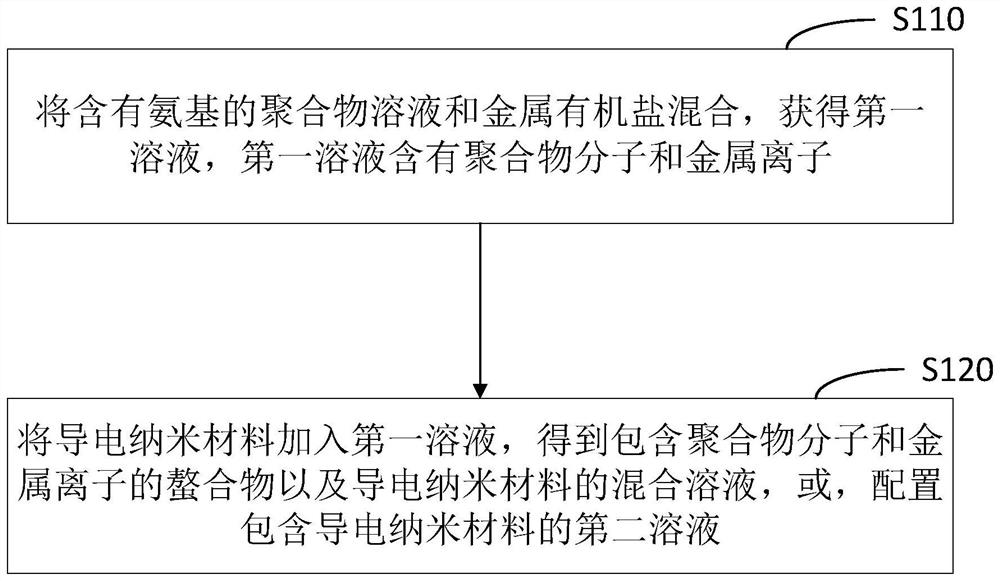

Method used

Image

Examples

Embodiment 1

[0049] Preparation of antistatic coating by spraying

[0050] (1) Configure the base material and covering material: first configure the PEIE solution with a mass fraction of 0.5%, the solvent is 2-methoxyethanol, add zinc acetate to make the mass of the polymer and the mass of zinc acetate 1:14, stir 0.5 h obtains a clear solution, and then it is diluted to a mass fraction of 20% to obtain the first solution;

[0051] (2) configure the antistatic coating material: add the Ag silver nanowire solution to the first solution above, so that the mass fraction of the Ag silver nanowire is 25%, and the mass ratio of the polymer to the Ag nanowire is 0.01:1. shake well;

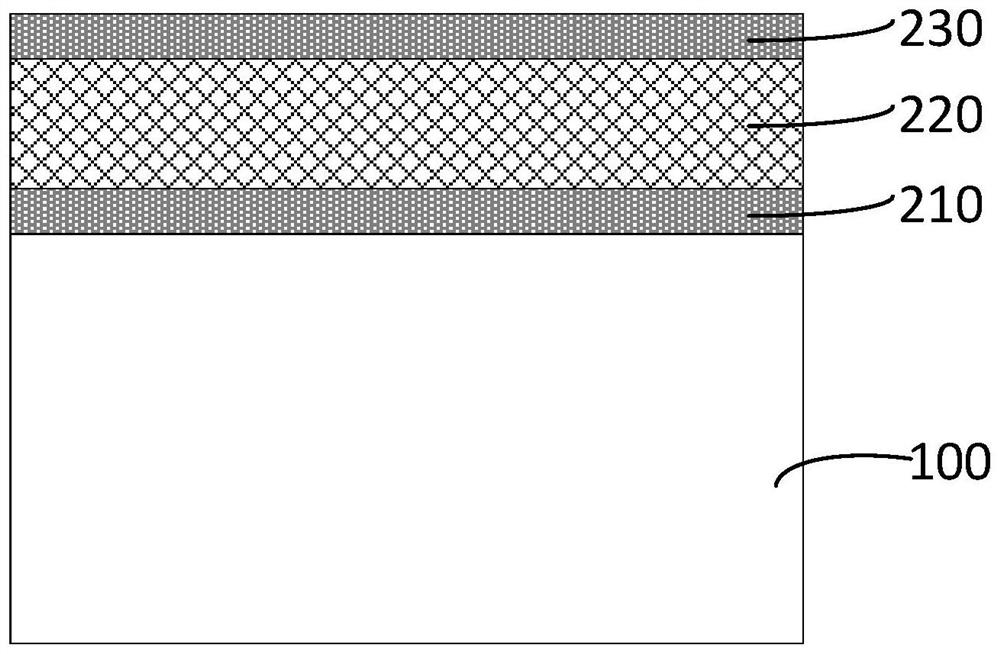

[0052] (3) Specific preparation process of antistatic coating: take 1.7×1.7cm 2 Use a large or small glass as the substrate, set the height of the spray gun constant, and keep the vertical distance at 20-25cm. Spray 300 μL of the substrate material on the cleaned glass sheet at room temperature, and heat it at 150°...

Embodiment 2

[0054] Preparation of antistatic coating by spin coating

[0055] (1) Configure the base material and covering material: first configure the PEIE solution with a mass fraction of 0.5%, the solvent is 2-methoxyethanol, add zinc acetate to make the mass of the polymer and the mass of zinc acetate 1:14, stir 0.5 h to obtain a clear solution;

[0056] (2) Add the Ag nanowire solution to the above-mentioned first solution, so that the mass fraction of the Ag nanowire is 25%, and the mass ratio of the polymer to the Ag nanowire is 0.01:1, and shake well;

[0057] (3) Specific preparation process of antistatic coating: take 1.7×1.7cm 2 The size of the glass is used as the substrate, and the substrate material is spin-coated on the cleaned glass sheet at a rotation speed of 4000rpm. After 45s, it is heated at 150°C for 10min to obtain the substrate layer. Spin-coat a layer of anti-static coating material on the above base layer at a speed of 5500rpm, heat at 150°C for 10 minutes aft...

Embodiment 3

[0059] Preparation of antistatic coating by scraping method:

[0060] (1) Configure the base material and covering material: first configure the PEIE solution with a mass fraction of 0.5%, the solvent is 2-methoxyethanol, add zinc acetate to make the mass of the polymer and the mass of zinc acetate 1:14, stir 0.5 h to obtain a clear solution;

[0061] (2) configure the antistatic coating material: the Ag silver nanowire solution is added in the above-mentioned first solution, so that the mass fraction of the Ag nanowire is 20%, and the mass ratio of the polymer to the Ag silver nanowire is 0.04:1. shake well;

[0062] (3) The specific preparation process of the antistatic coating: the 2.5×7.5cm 2 A clean glass slide was used as the substrate, and the clean glass slide was placed on a scraping platform with a substrate temperature of 50°C. Take 20 μL of substrate material, set the slit height to 150 μm, set the scraping speed to 10 mm / s, and scrape once. Afterwards, heat at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Square resistance | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com