Auxiliary anode assembly for cathode protection of ice breaker

A cathodic protection and auxiliary anode technology, which is applied in the field of electrochemistry, can solve the problems of failure to meet the design requirements of cathodic protection, the anode body is not isolated and protected, and the friction and wear of the auxiliary anode surface, so as to improve the mechanical wear resistance and high mechanical strength , easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

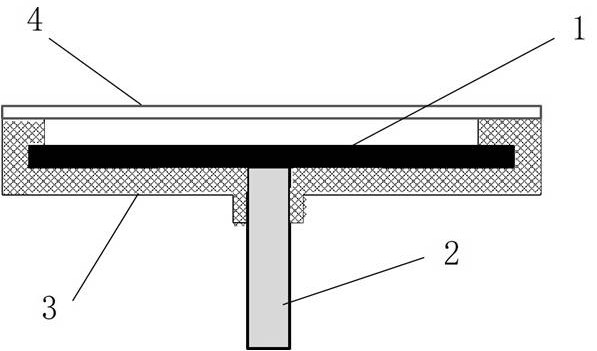

[0036]An auxiliary anode assembly for icebreaker cathodic protection of the present invention:

[0037] Firstly, a TA2 titanium plate is used as the anode substrate, its size is Φ150mm×6mm, and a 120mm copper-titanium composite rod is welded on the back. First, the titanium substrate was sandblasted, then etched in 10% oxalic acid solution for 2 hours, and rinsed with distilled water to obtain a pretreated titanium substrate. A boron-doped diamond film was prepared on a pretreated titanium substrate by plasma chemical vapor deposition, the film thickness was 5 μm, and the boron doping concentration was 2500 ppm. Then apply a mixed noble metal oxide coating containing iridium oxide and tantalum oxide, the iridium oxide content is 70%, and the coating thickness is 12 μm.

[0038] Then, the anode bracket is prepared by using glass fiber reinforced polyetheretherketone composite material and molding, and the anode body is embedded in the anode bracket and sealed by epoxy resin. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com