A kind of silicon dioxide nanocomposite material and its preparation method and application

A nano-composite material and silicon dioxide technology, applied in the field of nano-materials, can solve problems such as poor firmness of film and glass substrate, poor mechanical wear resistance and weather resistance, anti-reflection and anti-reflection durability, etc., to avoid stability problems, Excellent effect of improving wear resistance, stability and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0080] Embodiment 1-1 prepares silica nanoparticle suspension

[0081] Under the condition of condensation and reflux, stir 2L of ethanol and 100mL of concentrated ammonia water in a water bath at about 60°C; The reaction product is placed in a fume hood to remove ammonia water until the pH of the product reaches 7.0-7.5, and then a suspension of silica nanoparticles is obtained. The content of silica nanoparticles is about 7.5 mg / mL, which can be sealed and stored at room temperature.

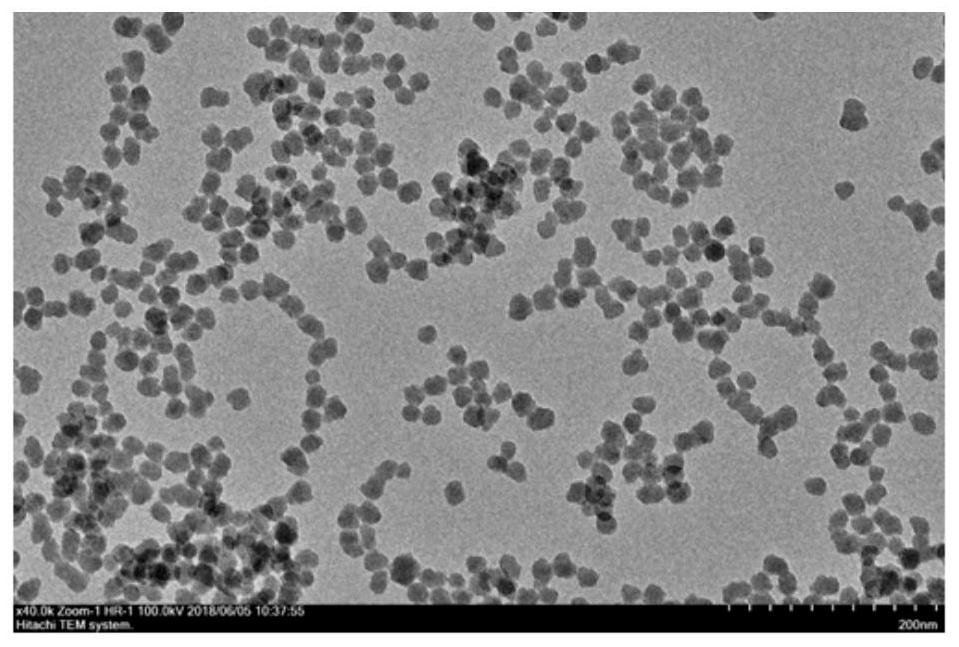

[0082] figure 1 is the transmission diagram of the silica nanoparticle suspension prepared above; by figure 1 It can be seen that the average particle diameter of the silica nanoparticles in the suspension prepared in this example is about 20 nm.

Embodiment 1-2

[0083] Embodiment 1-2 prepares silica nanoparticle suspension

[0084] Under the condition of condensation and reflux, stir 20L ethanol and 1000mL concentrated ammonia water in a water bath at about 60°C; The reaction product was placed in a fume hood to remove ammonia water until the pH of the product reached 7.0-7.5 to obtain a suspension of silica nanoparticles, wherein the content of silica nanoparticles was about 7.5mg / mL.

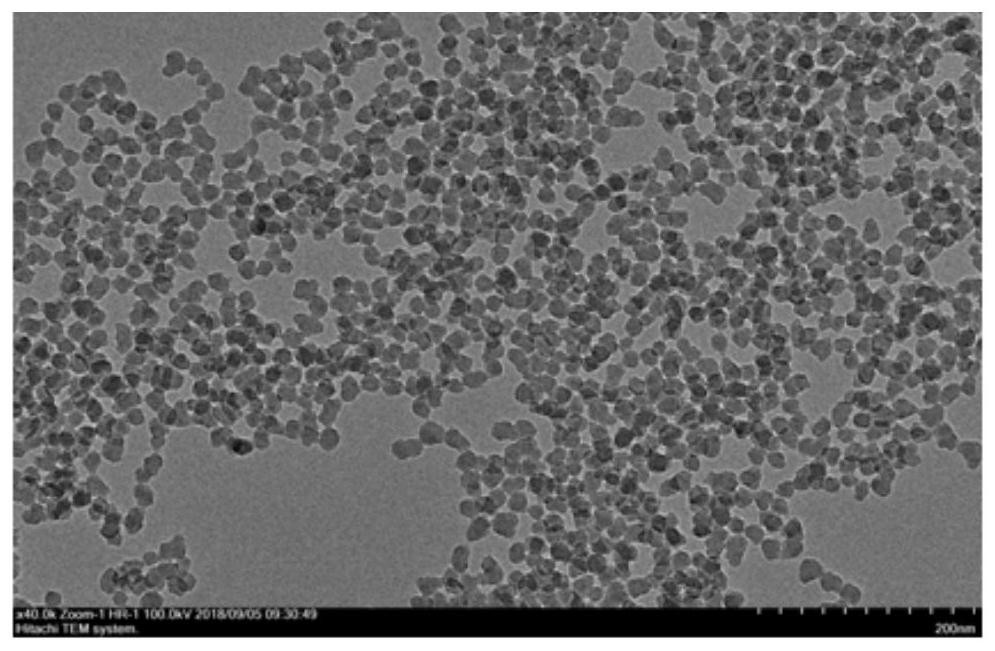

[0085] figure 2 is the transmission diagram of the silica nanoparticle suspension prepared above; by figure 2 It can be seen that the average particle diameter of silica nanoparticles in the suspension prepared in this embodiment is about 20nm; -30nm accounts for about 10%. It can be seen that the preparation method of the silica nanoparticle suspension of the present invention has good repeatability and stability, and can be prepared on a large scale according to actual production requirements.

Embodiment 1-3

[0086] Embodiment 1-3 prepares silica nanoparticle suspension

[0087] Under the condition of condensing and reflux, stir 20L ethanol and 800mL concentrated ammonia water in a water bath at about 30°C; The reaction product is placed in a fume hood to remove ammonia water until the pH of the product reaches 7.0-7.5, and then a suspension of silica nanoparticles is obtained, wherein the content of silica nanoparticles is about 4mg / mL, and the average particle size is about 10nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com