Self-cleaning coating with transmittance-increasing and wear-resisting functions and preparation method of self-cleaning coating

A self-cleaning and coating technology, applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of poor wear resistance and hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The present invention at first provides a kind of preparation method with antireflection and wear-resistant self-cleaning coating, and this method comprises:

[0024] Step 1: In a reaction vessel containing absolute ethanol, add ammonia water and ethyl orthosilicate, and stir mechanically at 60°C for 8-12 hours to obtain solid SiO 2 Nanoparticles; the volume ratio of the ammonia water and tetraethyl orthosilicate is preferably 5:3; the solid SiO 2 The particle size of the nanoparticles is preferably 25nm;

[0025] Step two: the solid SiO obtained in step one 2 Nanoparticles, cetyltrimethylammonium bromide and diethylamine are mixed, stirred in a 60°C water bath for 1-2 hours, and then ethyl orthosilicate is added to continue the reaction for 3 hours to obtain a reaction solution; the hexadecane The mass percentage of trimethylammonium bromide is preferably 25wt%, and described hexadecyltrimethylammonium bromide (ml): tetraethylorthosilicate (ml): diethylamine (g) is p...

Embodiment 1

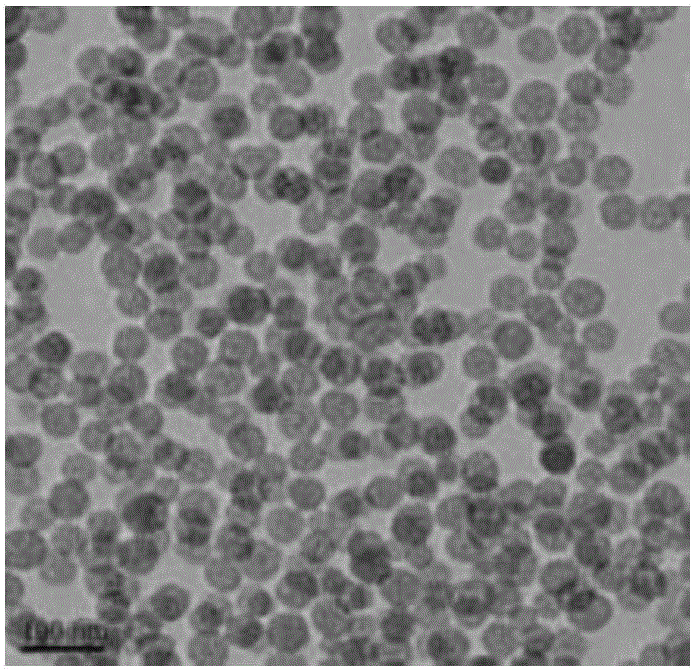

[0030] In a three-neck flask containing 100 mL of absolute ethanol, add 5 mL of ammonia water, add dropwise 3 mL of tetraethyl orthosilicate under stirring at 60 ° C, and mechanically stir for 8 hours to obtain solid SiO with a particle size of 25 nm. 2 Nanoparticles: Add 8mL of cetyltrimethylammonium bromide (25wt%) and 0.2g of diethylamine to the above system, stir in a water bath at 60°C for 2h, then add 5mL of tetraethyl orthosilicate to continue Stirring reaction 3h, in above-mentioned system, add the hydrogen peroxide (H2O2) of 8mL 2 o 2 30%), mechanically stirred for 6 hours, centrifuged to obtain a solid precipitate, and washed with deionized water and ethanol for 3 to 5 times to obtain porous SiO with a particle size of 20 to 100 nm. 2 Self-cleaning paint.

[0031] figure 1 For the prepared SiO of embodiment 1 2 TEM images of the nanoparticles, from figure 1 It can be seen that the preparation method of the present invention can obtain porous SiO with different p...

Embodiment 2

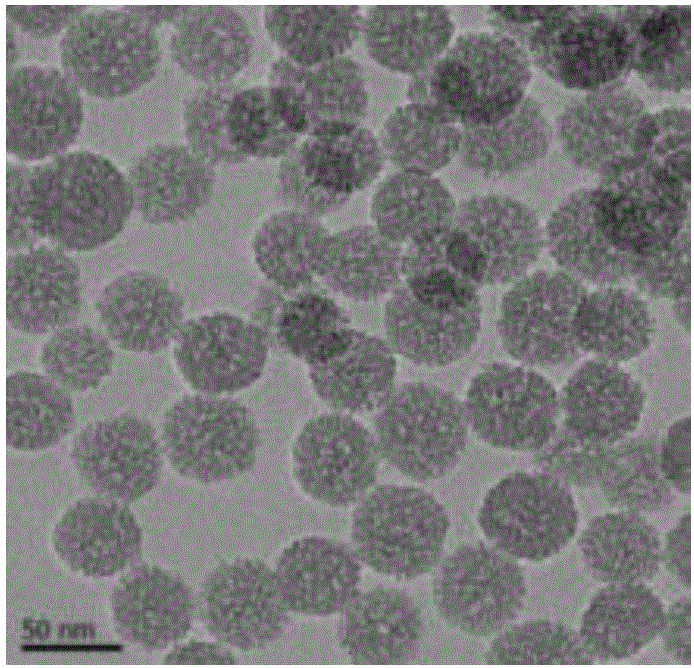

[0039] In a three-neck flask containing 100 mL of absolute ethanol, add 10 mL of ammonia water, add 6 mL of tetraethyl orthosilicate dropwise under stirring at 60 ° C, and mechanically stir for 10 h to obtain solid SiO with a particle size of 25 nm. 2 Nanoparticles: Add 10mL of cetyltrimethylammonium bromide (25wt%) and 0.3g of diethylamine to the above system, stir in a water bath at 60°C for 2h, then add 7mL of tetraethyl orthosilicate to continue Stirring reaction 3h, in above-mentioned system, add the hydrogen peroxide (H2O2) of 10mL 2 o 2 30%), mechanically stirred for 8 hours, centrifuged to obtain a solid precipitate, washed with deionized water and ethanol for 3 to 5 times, and obtained a porous SiO with a particle size of 20 to 100 nm. 2 Self-cleaning paint.

[0040] figure 2 For the prepared SiO of embodiment 2 2 TEM images of the nanoparticles, from figure 2 It can be seen that the preparation method of the present invention can obtain porous SiO with differe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com