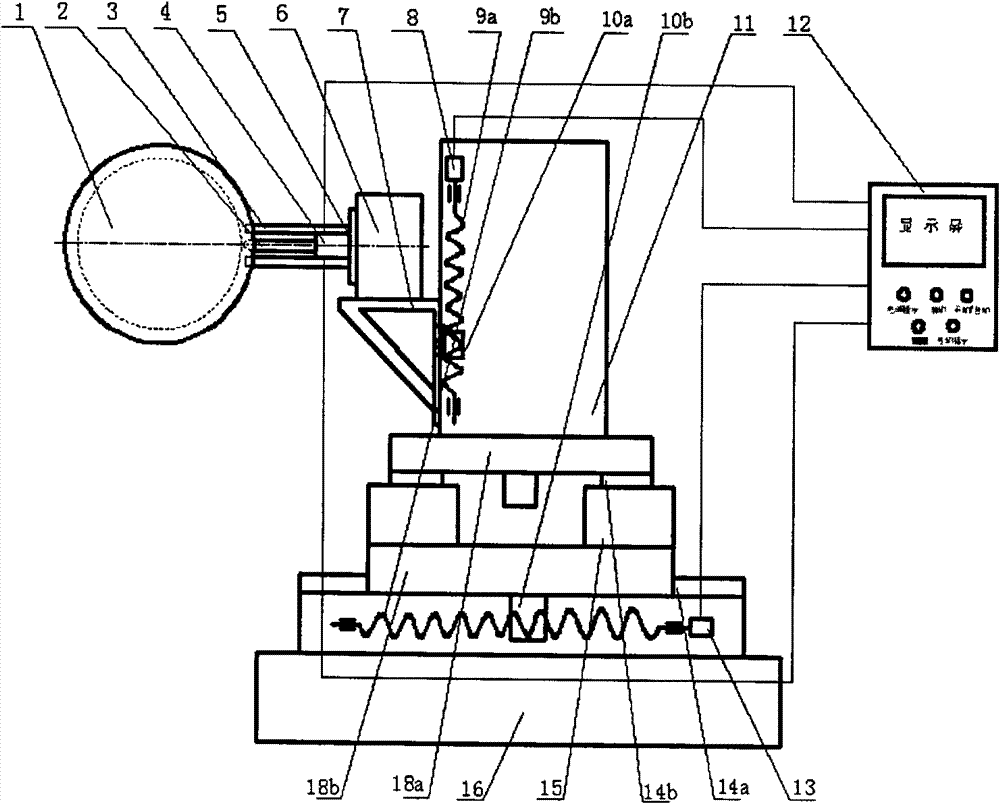

Device for automatically detecting relative position of quenching sensor and rotary supporting raceway

A technology of automatic detection device and quenching sensor is applied in the direction of quenching device, process efficiency improvement, heat treatment equipment, etc. The effect of fast response performance and high mechanical wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

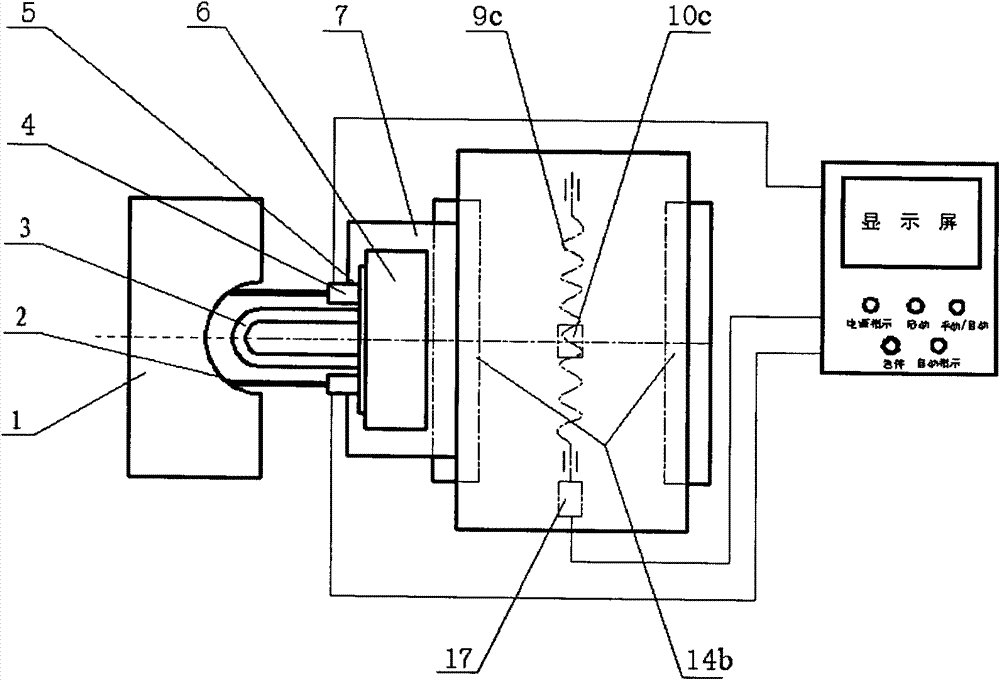

[0012] The quenching sensor is consistent with the automatic control detection principle of the position between the inner and outer raceways of the slewing ring. According to the different pressure signals fed back by the pressure sensor, the control system controls the displacement of the quenching sensor in the three directions of x, y and z through PLC. The specific implementation method is: press the power button, the power indicator light is on, press the start button, the start indicator light is on, at this time, the pressure signal of the ruby probe is fed back to the control system through the pressure sensor. like figure 2 The pressure of the upper pressure sensor is greater than (or less than) the pressure of the lower part, then the control device is controlled by PLC figure 2 In the third servo motor 17, the ball screw rotates, and the nut and the slide plate move linearly in the negative y direction (or positive y direction) along the guide rail until the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com