Sampling device with diamond-like carbon coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

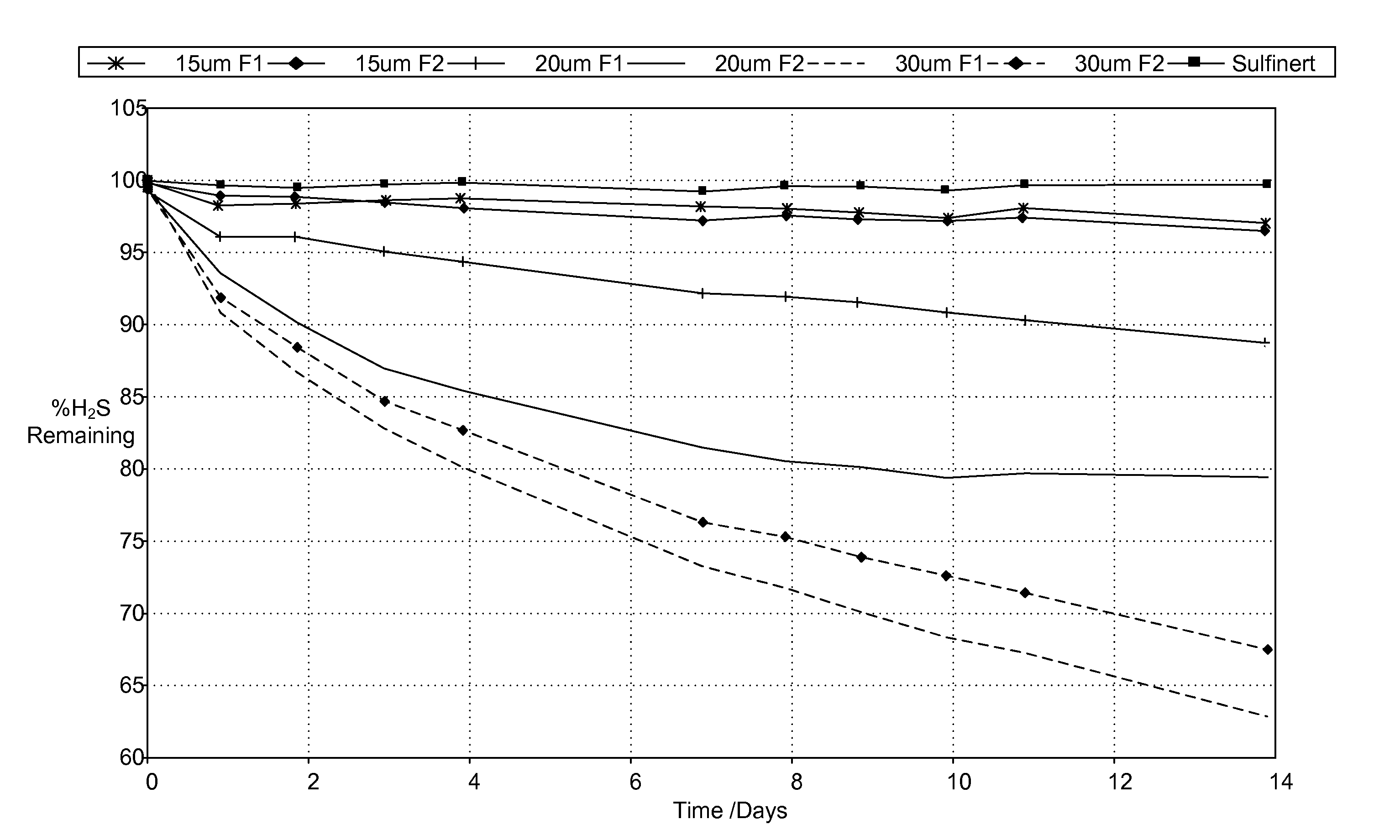

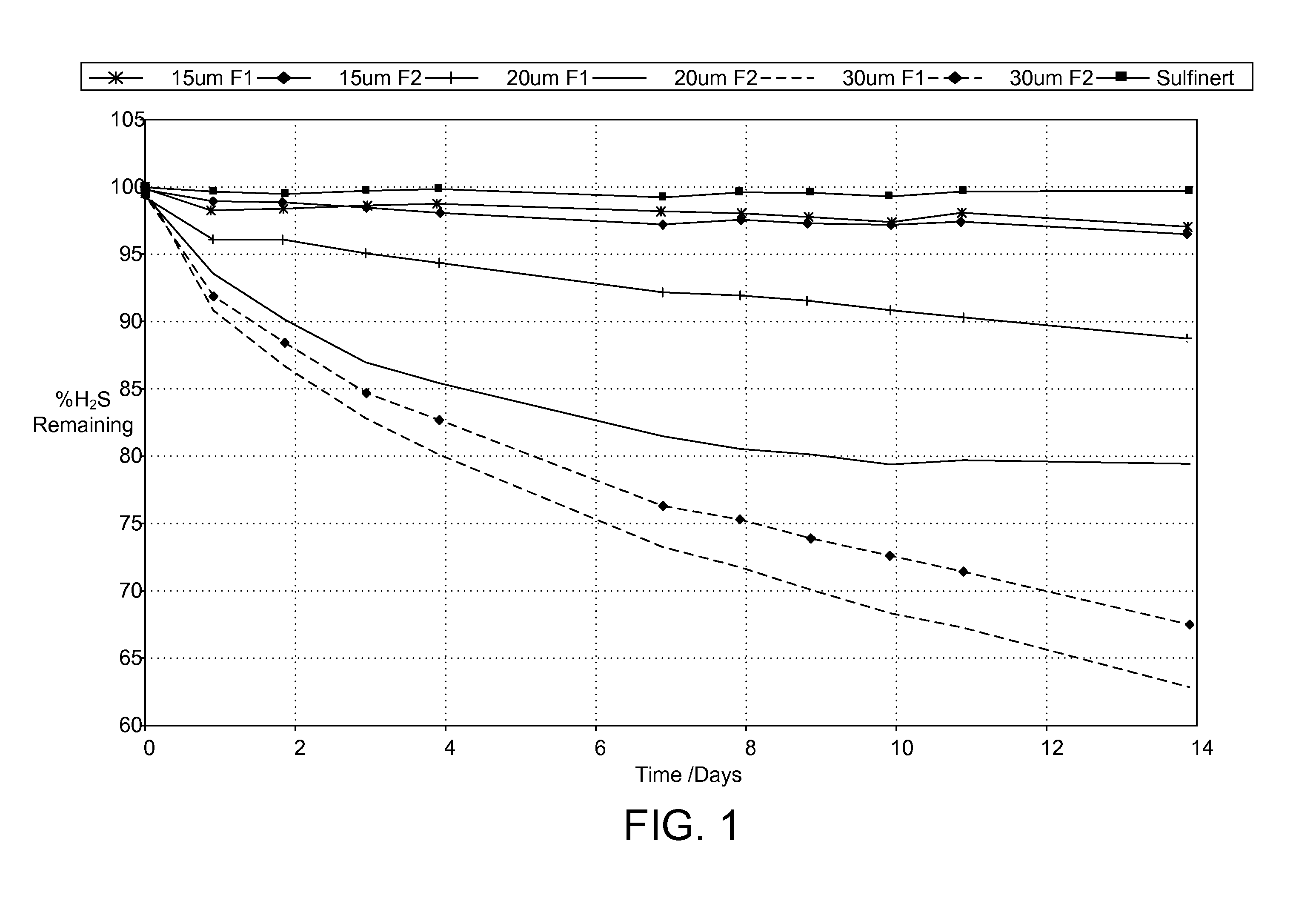

[0025]Several tests are carried out using samplers having diamond-like carbon coatings covering all internal surfaces in contact with the sample and using two different formulations. A first formulation F1 includes a diamond-like carbon top layer, and a first layer with graded, silicon containing diamond-like carbon, for optimized adhesion to the metal. A second formulation F2 is used, including a top layer and a first layer, with both layers made of silicon-containing diamond-like carbon. The overall thickness of each coating formulation is adjusted by controlling the number of intermediate layers.

[0026]Both formulations F1 and F2 include a dense, amorphous, diamond-like carbon, with high carbon diamond bonding (sp3 content greater than about 65%, as shown by RAMAN). Total composition of each formulation is about 70 percent (%) carbon and about 30 percent (%) hydrogen. Silicon is added to the first layer of formulation F1 to promote adhesion to the metal of the sampler. The coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com