Floating device providing noise reduction properties

a technology of noise reduction and floating devices, which is applied in the direction of sound producing devices, trickle coolers, building components, etc., can solve the problems of high noise reduction costs, severe damage or at least accelerated fatigue of installation, and the worst conditions in cooling towers for any kind of sound dampening installation, etc., to achieve a significant and sustainable level of noise reduction and high mechanical wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0029]Preparation of Test Samples

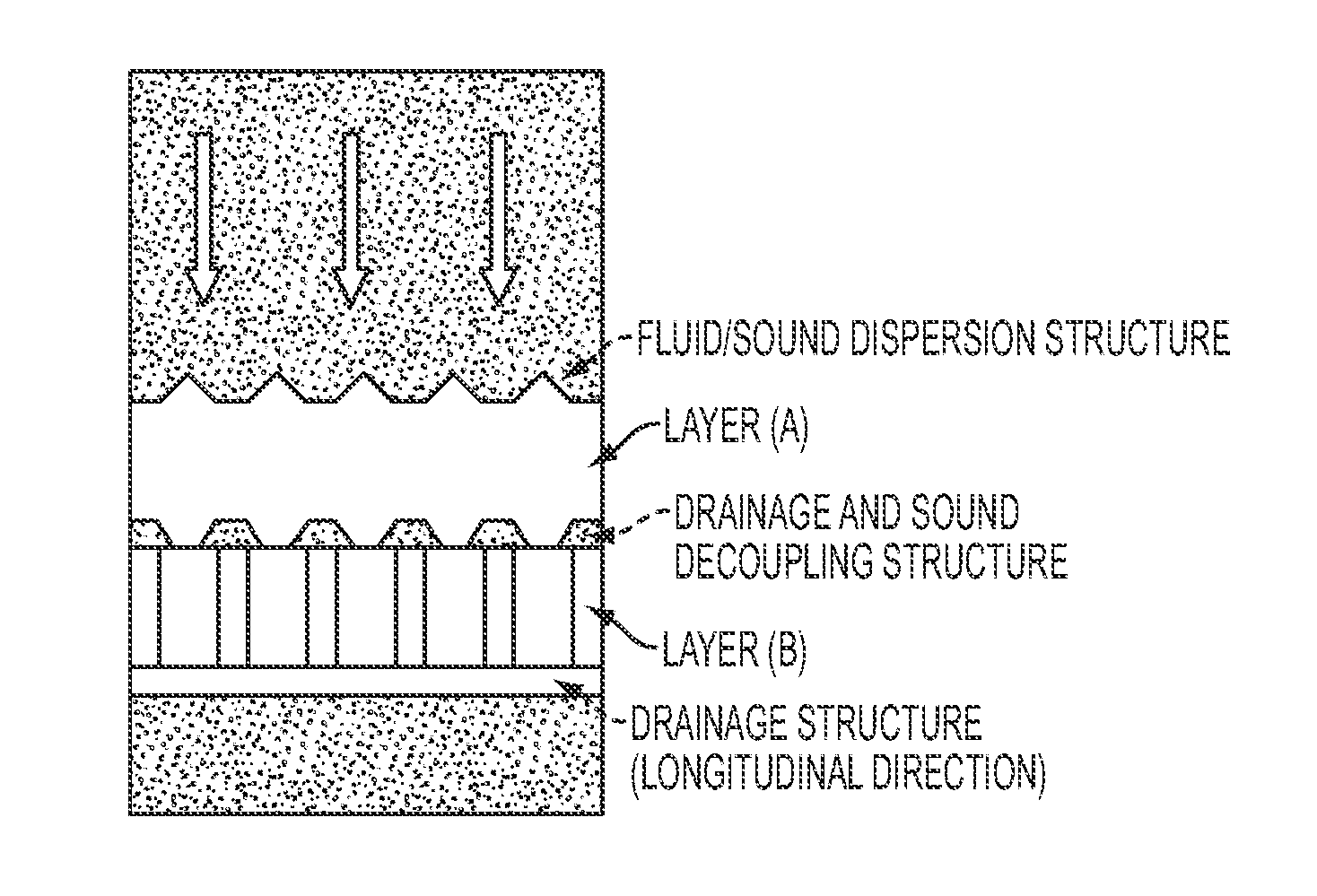

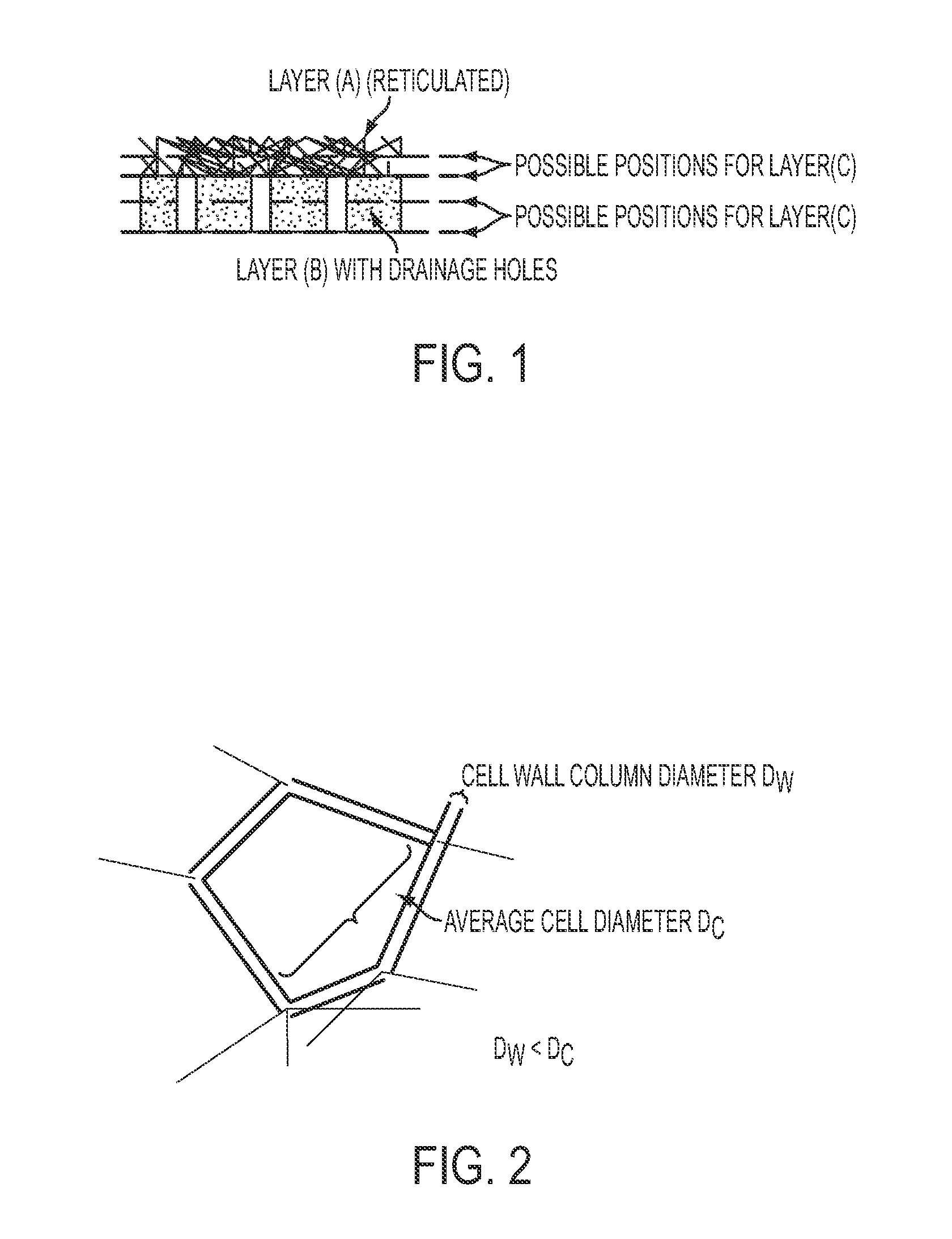

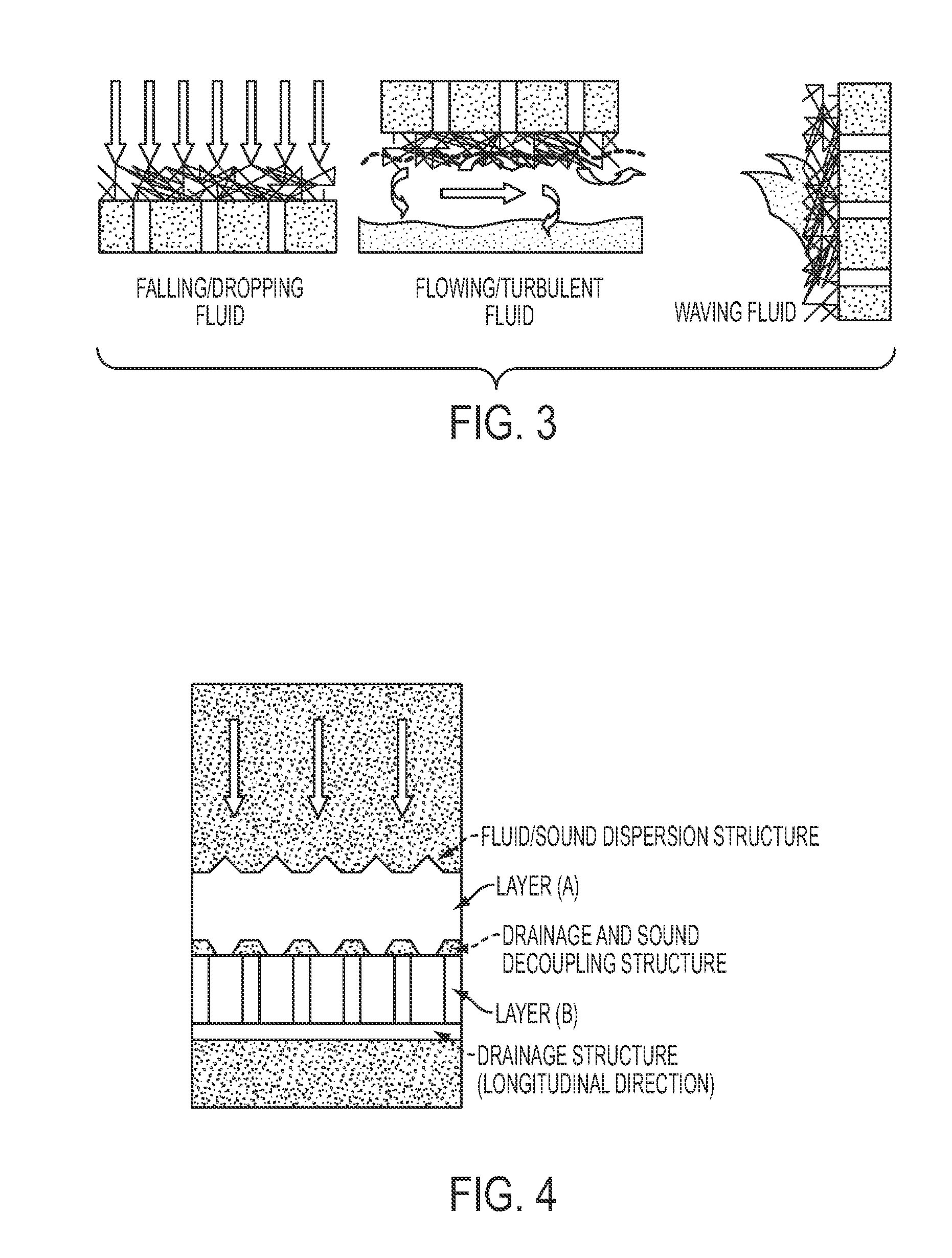

[0030]1. Floating layer (B): an extruded, expanded and cut PET board of 25 mm thickness and 1000×1000 mm width (ArmaStruct®, Armacell, Münster, Germany) was coated with a silicone adhesive layer (ELASTOSIL® R plus 4700, Wacker Chemie, München, Germany) to give the floating part of the system. A sinus shape ridge structure (distance peak to peak of 35 mm) was applied to one surface by thermoforming embossing and pin holes of 20 mm diameter were drilled into the board in a distance of 80 mm.

[0031]2. Sponge like open cell absorbing layer (A): A rubber compound (Armaprene® N H, Armacell, Münster, Germany) was extruded, expanded and cut to an open cell foam mat of 25 mm thickness and 1000×1000 mm width and then laminated onto the plain surface of (B) as single or double layer by heating the composite up to 120° C. in a hot air oven, using the a.m. adhesive.

[0032]3. Skeleton structure open cell absorbing layer (A): A reticulated polyurethane foam mat of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com