High reflectivity multilayer heat insulation window film, and preparation method thereof

A technology of multi-layer heat insulation and reflection layer, applied in chemical instruments and methods, coatings, layered products, etc., can solve the problem of low infrared reflectivity of window film, achieve good heat conduction effect, stable chemical properties, good The effect of mechanical wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

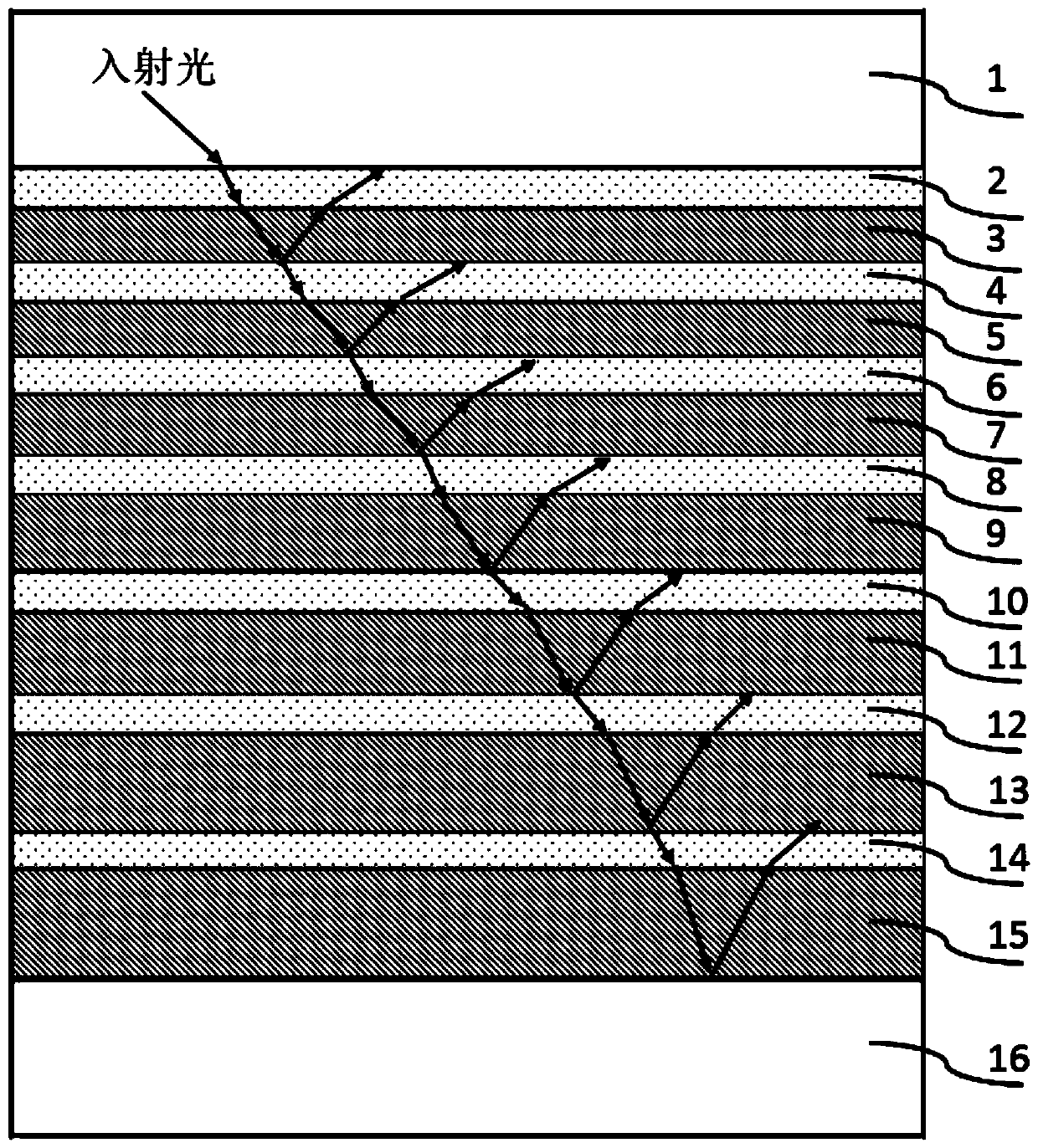

[0041] Such asfigure 1 As shown, a PET / Cu / ZrO 2 / Cu / ZrO 2 ~Cu / ZrO 2 / Cu / ZrO 2 / PET multi-layer thermal insulation window film, its structure is PET sealing layer 1, first reflective layer 2, second reflective layer 3, third reflective layer 4, fourth reflective layer 5, fifth reflective layer 6 , the sixth reflective layer 7, the seventh reflective layer 8, the eighth reflective layer 9, the ninth reflective layer 10, the tenth reflective layer 11, the eleventh reflective layer 12, the twelfth reflective layer 13, the thirteenth reflective layer 14. The fourteenth reflective layer 15 and the PET base layer 16;

[0042] The PET sealing layer 1 and the PET base layer 16 are made of PET with a thickness of 50 μm;

[0043] The first reflective layer 2, the third reflective layer 4, the fifth reflective layer 6, the seventh reflective layer 8, the ninth reflective layer 10, the eleventh reflective layer 12 and the thirteenth reflective layer 14 are made of Cu, with a thickness ...

Embodiment 2

[0064] A PET / Cu / ZrO 2 / Cu / ZrO 2 ~Cu / ZrO 2 / Cu / ZrO 2 / PET multi-layer thermal insulation window film, its structure is PET sealing layer 1, first reflective layer 2, second reflective layer 3, third reflective layer 4, fourth reflective layer 5, fifth reflective layer 6 , the sixth reflective layer 7, the seventh reflective layer 8, the eighth reflective layer 9, the ninth reflective layer 10, the tenth reflective layer 11, the eleventh reflective layer 12, the twelfth reflective layer 13, the thirteenth reflective layer 14. The fourteenth reflective layer 15 and the PET base layer 16;

[0065] The PET sealing layer 1 and the PET base layer 16 are made of PET with a thickness of 45 μm;

[0066] The first reflective layer 2, the third reflective layer 4, the fifth reflective layer 6, the seventh reflective layer 8, the ninth reflective layer 10, the eleventh reflective layer 12 and the thirteenth reflective layer 14 are made of Cu, with a thickness of 45nm;

[0067] The se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com