Hydrophobic SiO2 nano mixed liquor, functional coating and preparation

A mixed liquid and nanotechnology, applied in the field of nanomaterials, can solve the problems of time-consuming and labor-intensive, self-cleaning, anti-fog effect, durability and convenience, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Preparation of hydrophobic SiO 2 Nanoparticle suspension:

[0073] Stir and mix 50mL ethanol and 1.25mL concentrated ammonia water in a water bath at about 60°C; after the temperature is constant, add 1.5mL tetraethoxysilane to the above mixed solution, and continue to stir for 12 hours. SiO modified with superhydrophobic groups 2 Nanoparticles. Add 0.5 mL of 1H, 1H, 2H, 2H-perfluorooctyltriethoxysilane to the above mixed solution, stir again for 24 hours, then place the reaction product in a fume hood to remove ammonia until the pH of the product reaches 7.0- 7.5, to obtain hydrophobic SiO modified by organofluorine functional groups 2 The nanoparticle suspension was then diluted to three times the original volume with ethanol, in which the hydrophobic SiO 2 The content of nanoparticles is about 12.9mg / mL, which can be sealed and stored at room temperature.

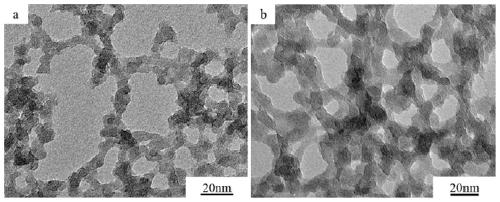

[0074] figure 1 a is the SiO of the unmodified hydrophobic group prepared above 2 Transmission electron ...

Embodiment 2

[0076] Preparation of nano-SiO 2 Acid sol:

[0077] At room temperature (25°C), add a certain amount of concentrated hydrochloric acid to deionized water to prepare dilute hydrochloric acid with a concentration of 1-5 mg / mL; then, add 4.52 mL of dilute hydrochloric acid solution to 135 mL of ethanol, stir and mix Evenly, the final concentration of hydrochloric acid is 0.032-0.16mg / mL.

[0078]14mL tetraethoxysilane was added in the above-mentioned mixed solution, after stirring and reacting at room temperature for 4 hours, then left to stand at room temperature and reacted for 4 days to obtain nano-SiO 2 Acidic sol, in which chain-like nano-SiO 2 The content is about 84.8mg / mL and can be stored at 4°C.

[0079] The solid-state nuclear magnetic resonance was used to detect, and the results showed that the above-prepared nano-SiO 2 The condensation degree of the acidic sol is about 80%.

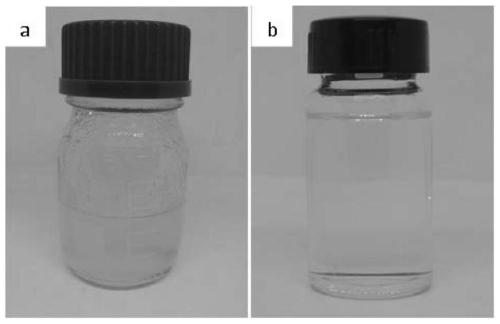

[0080] image 3 For the above prepared nano-SiO 2 Digital photograph of an acidic so...

Embodiment 3-1

[0082] Hydrophobic SiO 2 Preparation of nanomixture:

[0083] Under stirring condition, to the hydrophobic SiO prepared in 35mL embodiment 1 2 Slowly add the nano-SiO prepared by 0.6mL embodiment 2 in the nanoparticle suspension 2 Acidic sol; stir for 3-10 minutes to obtain hydrophobic SiO 2 Nanomixture.

[0084] Figure 4 a is the hydrophobic SiO prepared above 2 Transmission map of the nanohybrid solution. Cross-linked silica nanoparticles form a three-dimensional network structure, and nano-SiO 2 The chain-like substance forms a small amount of floc, which appears in the middle of the network structure, and acts like glue to increase the degree of adhesion between particles and between particles and the substrate, increasing the firmness of the coating. Figure 4 b is the hydrophobic SiO prepared above 2 Digital photo of the nanomixture. It can be seen from 4b that SiO 2 The nanomixture is a clear and transparent solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com