Silicon dioxide hollow sphere nano composite material, and preparation and application thereof

A nano-composite material, silica technology, applied in the field of nano-materials, can solve the problems of self-cleaning and anti-fog effects, unsatisfactory durability, high cost, and many components, etc., and achieves easy operation and application, good mechanical resistance. Good abrasiveness and process operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

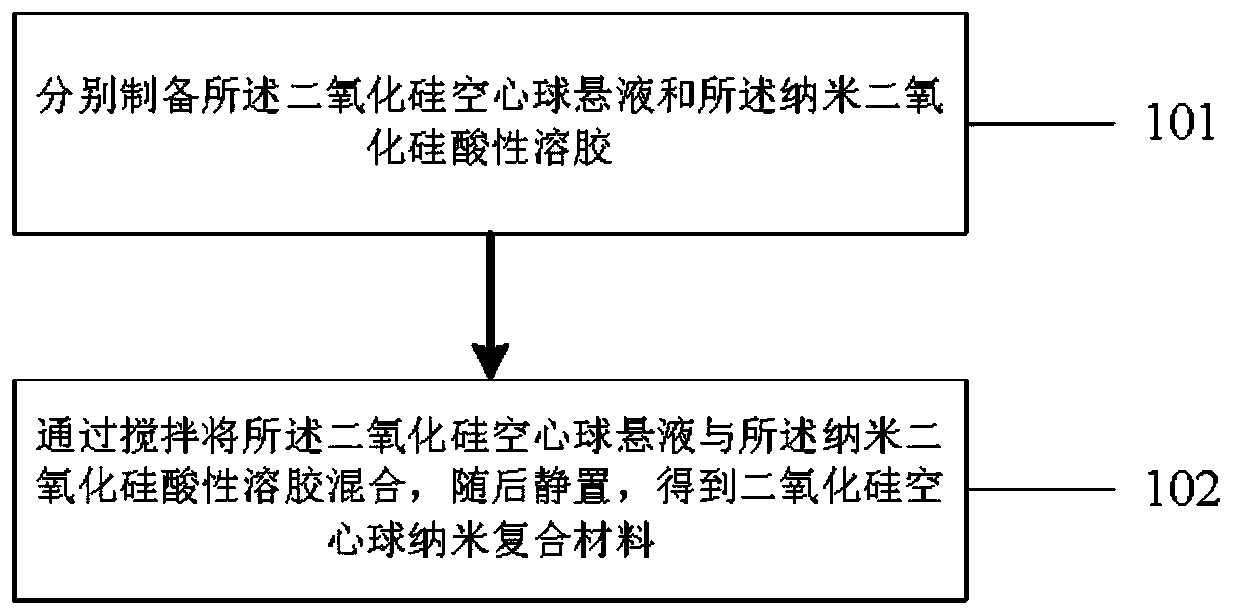

Method used

Image

Examples

preparation example Construction

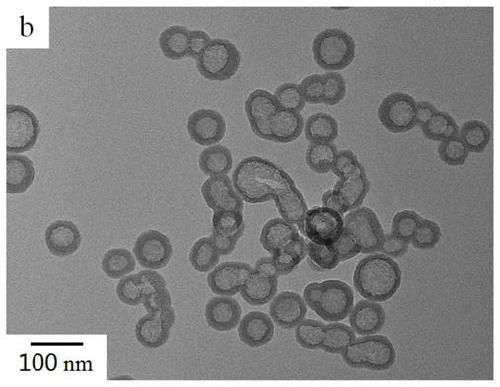

[0055] More specifically, the preparation method of the silica nano-hollow sphere suspension may include: reacting raw materials containing solvent, lye, polyacrylic acid and alkoxysilane. The conditions of the above reaction are not strictly limited, as long as it is convenient to prepare the silica hollow sphere suspension with the above quality requirements of the present invention. The molecular weight of polyacrylic acid is controlled at 2000-1000; specifically, the volume ratio between solvent, lye, polyacrylic acid and alkoxysilane can be controlled to be 90:3-6:0.4-0.8:1-3. The range is favorable for preparing the above-mentioned specific silica hollow spheres.

[0056] The hollow spheres are washed repeatedly with water to remove polyacrylic acid, ammonia water, etc. in the hollow sphere suspension. Disperse the washed hollow spheres in ethanol to prepare for the configuration of hollow sphere composite nanomaterials.

[0057] Studies have found that the above prepa...

Embodiment 1

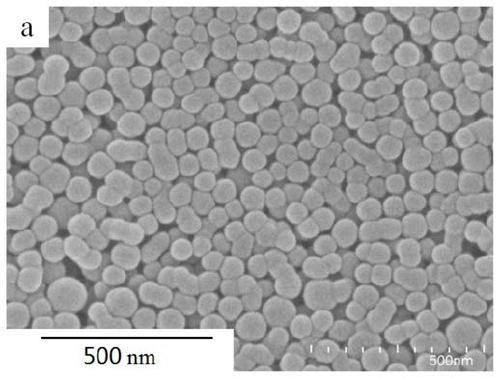

[0071] Preparation of silica nano-hollow spheres with a particle size of 20-120nm:

[0072] (1) Add 0.4 to 0.8 milliliters of polyacrylic acid solution with a molecular weight of 5000 (wherein the mass percentage of polyacrylic acid is 50%) into 3 to 6 milliliters of ammonia water, and stir in a water bath at 25 degrees Celsius;

[0073] (2) 90 milliliters of ethanol is joined in the 500 milliliter flask, the mixed solution in (1) is joined in the flask, stirred in a water bath at 25 degrees Celsius;

[0074] (3) Add 1-3 milliliters of tetraethoxysilane into the mixed solution in (2) at 25 degrees Celsius, and continue stirring for 10-20 hours to obtain the hollow silicon dioxide nanospheres.

[0075] (4) Obtain the precipitate of hollow silicon dioxide nanospheres by centrifugation, add 500 milliliters of water, perform ultrasonic treatment for 30 minutes, and then perform centrifugation to remove polyacrylic acid. This washing process is repeated twice. Finally, the obtaine...

Embodiment 2

[0078] Preparation of nano-silica acidic sol:

[0079] At room temperature (25°C), add 0.05-0.2mL of concentrated hydrochloric acid (37%) into 5-20mL of water to make a dilute hydrochloric acid solution; then, add the above-mentioned dilute hydrochloric acid solution into 200-300mL of ethanol, stir and mix well .

[0080] Add 10-40mL tetraethoxysilane to the above mixed solution, stir and react at room temperature for 4 hours, and then react at room temperature for 4 days to obtain nano-silica acidic sol, which can be stored at 4°C.

[0081] The solid-state nuclear magnetic resonance is used for detection, and the results show that the condensation degree of the nano-silica acidic sol prepared above is about 70-90%, and the average length of the chain nano-silica is about 5nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com