A kind of preparation method of thermal transfer paper release agent, prepared thermal transfer paper release agent and application thereof

A thermal transfer and solvent technology, applied in powder coatings, coatings, etc., can solve the problems of easy deterioration, easy powder agglomeration, poor powder storage stability, etc., to improve mechanical wear resistance, improve stability, and improve vacuum. The effect of de-papering efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

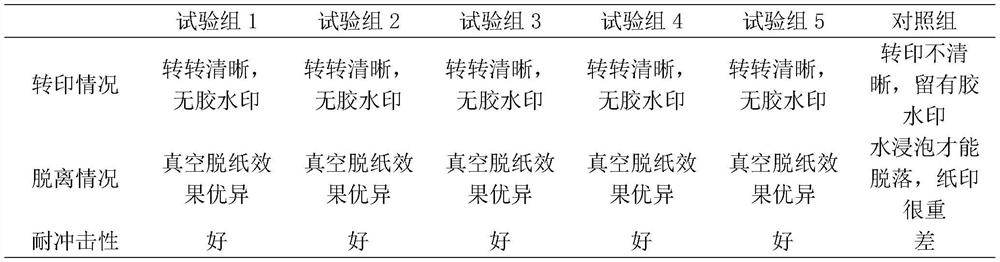

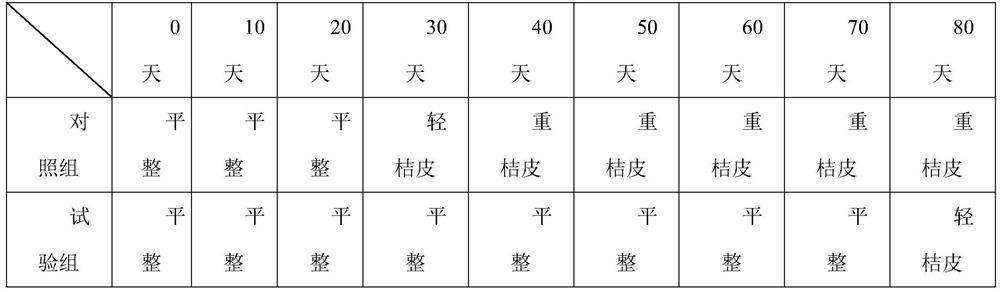

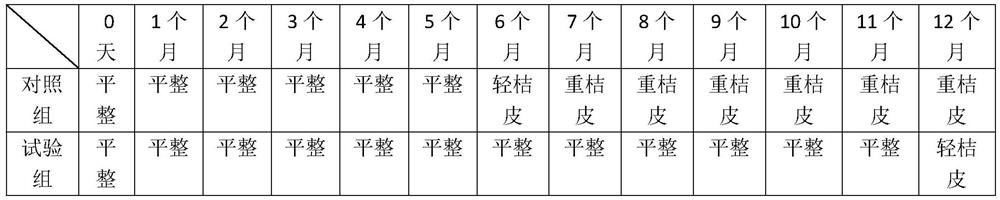

Examples

Embodiment 1

[0040] Preparation of carboxylic acrylic resin: 20Kg of acrylic acid monomer, 40Kg of isobornyl methacrylate, 10Kg of styrene, 13Kg of mercaptoethanol and 5Kg of benzoyl peroxide were uniformly mixed to prepare a mixed base material. Inject toluene into the reaction kettle, and start adding the above-prepared mixed base material dropwise when the toluene is heated to reflux. The reaction temperature is 150°C. After reflux reaction for 3 hours, the solvent is heated to 250°C to remove the solvent and cooled to obtain carboxylic acrylic resin. The obtained carboxyl acrylic resin was passed through a 160 mesh sieve, and its acid value was determined to be 32.

[0041] Preparation of epoxy-based acrylic resin: 40Kg of ethyl acrylate monomer, 45Kg of styrene, 10Kg of mercaptoethanol, 3Kg of benzoyl peroxide and 2Kg of tert-butyl peroxybenzoate were uniformly mixed to prepare a mixed base material. Inject xylene into the reaction kettle, and start adding the mixed base material drop...

Embodiment 2

[0044] Preparation of carboxyl acrylic resin: mix 25Kg methacrylic acid monomer, 35Kg lauryl methacrylate, 22Kg styrene, 15Kg mercaptoacetic acid, 1Kg benzoyl peroxide and 2Kg tert-butyl peroxybenzoate to make a mixed bottom material. Inject xylene into the reaction kettle, and start to add the mixed base material prepared above dropwise when the xylene is heated to reflux. The reaction temperature is 135°C. After 3.5 hours of reflux reaction, the solvent is heated to 240°C to remove the solvent and cool to obtain carboxyl Acrylic. The obtained carboxyl acrylic resin was passed through a 160 mesh sieve, and its acid value was determined to be 60.

[0045] Preparation of epoxy-based acrylic resin: 45Kg of glycidyl methacrylate (GMA), 35Kg of styrene, 15Kg of thioglycolic acid and 4Kg of benzoyl peroxide were uniformly mixed to prepare a mixed base material. Inject toluene into the reaction kettle, and start adding the mixed base material dropwise when the toluene is heated to r...

Embodiment 3

[0048] Preparation of carboxylic acrylic resin: 30Kg of acrylic acid monomer, 30Kg of butyl acrylate, 20Kg of styrene, 10Kg of isooctyl 3-mercaptopropionate, and 6Kg of tert-butyl peroxybenzoate were uniformly mixed to prepare a mixed base material. Inject xylene into the reaction kettle, and start to add the mixed bottom material prepared above dropwise when the xylene is heated to reflux. The reaction temperature is 130°C. After reflux reaction for 4 hours, the solvent is heated to 220°C to remove the solvent and cool to obtain carboxylic acid. resin. The obtained carboxyl acrylic resin was passed through a 160 mesh sieve, and its acid value was determined to be 52.

[0049] Preparation of epoxy acrylic resin: 55Kg butyl methacrylate monomer, 35Kg styrene, 6Kg mercaptoethanol, 6Kg mercaptoacetic acid and 3Kg tert-butyl peroxybenzoate were uniformly mixed to prepare a mixed base material. Inject xylene into the reaction kettle, and start adding the mixed base material dropwi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com