A method for preparing rare earth oxides using microwave technology

A rare earth oxide and microwave technology, which is applied in the preparation/processing of rare earth metal oxides/hydroxides, rare earth metal compounds, energy input, etc., can solve the problems of insufficient heat dissipation of water vapor, uneven burning, uneven heating, etc. , to avoid rare earth powder agglomeration, reduce production cost and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

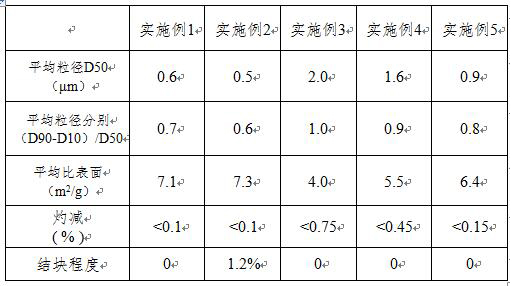

Examples

Embodiment 1

[0031] A method for preparing rare earth oxides using microwave technology, comprising the following steps:

[0032] (1) Microwave drying: Put the rare earth oxalate into the microwave equipment, turn on the microwave radiation, the frequency is 915 MHz, raise the temperature to 130 °C at a heating rate of 25 °C / min, microwave drying for 20 min, and the power is 80 KW / m 3 , until the water content of rare earth oxalate is 3%;

[0033] (2) Microwave preheating: Turn on the microwave frequency of 2.45 GHz, raise the temperature to 400°C at a heating rate of 15°C / min, preheat with microwave for 30 minutes, and power 160 KW / m 3 , until the water content of rare earth oxalate is 0;

[0034] (3) Microwave burning: turn on the microwave frequency of 5.80 GHz, raise the temperature to 950 °C at a heating rate of 5 °C / min, and microwave burning for 50 min with a power of 280 KW / m 3 ;

[0035] (4) Gradient air-cooling cooling: During the air-cooling cooling process, the cooling rate ...

Embodiment 2

[0037] A method for preparing rare earth oxides using microwave technology, comprising the following steps:

[0038] (1) Microwave drying: Put the rare earth oxalate or rare earth carbonate into the microwave equipment, turn on the microwave radiation, the frequency is 915MHz, raise the temperature to 150°C at a heating rate of 30°C / min, microwave drying for 10 minutes, and the power is 100 KW / m 3 , until the water content of rare earth oxalate or rare earth carbonate is 3%;

[0039] (2) Microwave preheating: turn on the microwave frequency of 2.45 GHz, raise the temperature to 500°C at a heating rate of 20°C / min, preheat with microwave for 20 minutes, and power 180 KW / m 3 , until the water content of rare earth oxalate or rare earth carbonate is 0;

[0040] (3) Microwave burning: turn on the microwave frequency of 5.80 GHz, raise the temperature to 1000 °C at a heating rate of 10 °C / min, microwave burning for 30 min, and the power is 300 KW / m 3 ;

[0041] (4) Gradient ai...

Embodiment 3

[0043] A method for preparing rare earth oxides using microwave technology, comprising the following steps:

[0044] (1) Microwave drying: Put the rare earth oxalate or rare earth carbonate into the microwave equipment, turn on the microwave radiation, the frequency is 915MHz, raise the temperature to 140°C at a heating rate of 28°C / min, microwave drying for 15 minutes, and the power is 70 KW / m 3 , until the water content of rare earth oxalate or rare earth carbonate is 5%;

[0045] (2) Microwave preheating: turn on the microwave frequency of 2.45 GHz, raise the temperature to 300 °C at a heating rate of 18 °C / min, and microwave preheating for 60 min with a power of 150 KW / m 3 , until the water content of rare earth oxalate or rare earth carbonate is 0;

[0046](3) Microwave burning: Turn on the microwave frequency of 5.80 GHz, raise the temperature to 700 °C at a heating rate of 8 °C / min, microwave burning for 40 min, and the power is 250 KW / m 3 ;

[0047] (4) Gradient a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com