Polymer brush modified transparent anti-fog patch and preparation method thereof

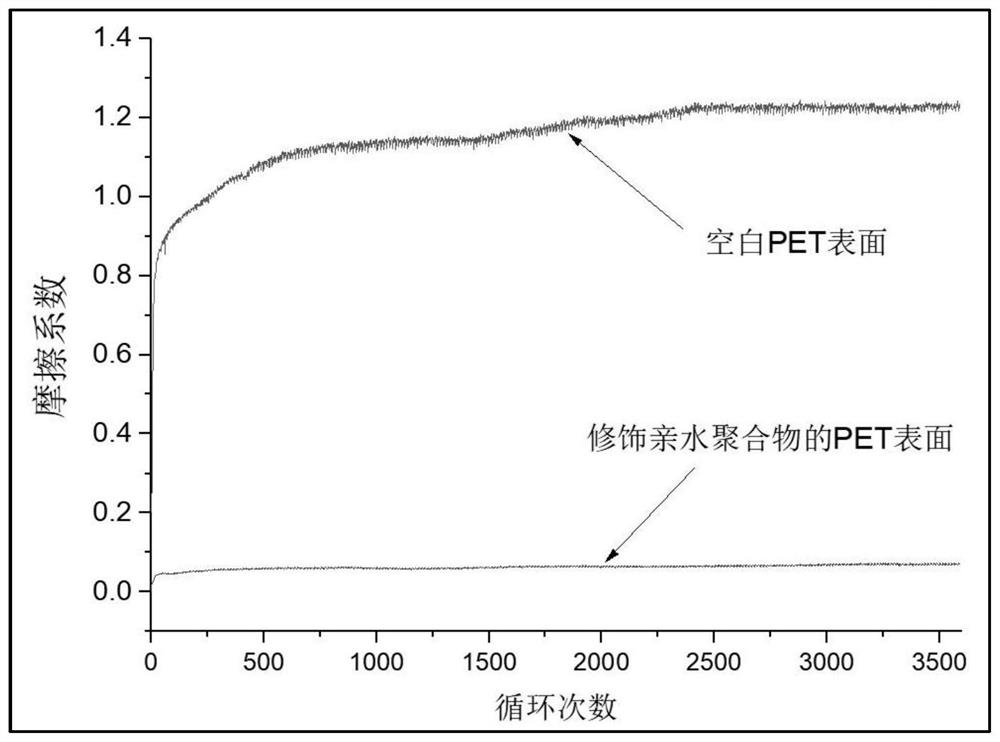

A polymer brush, hydrophilic polymer technology, applied in the direction of film/flake adhesives, adhesives, etc., can solve the problem of long-term anti-fog performance, poor mechanical wear resistance, wear resistance, anti-fog long-term effect Poor stability, users cannot remove and replace by themselves, etc., to avoid the decline of anti-fog performance, improve the anti-fog effect, and maintain a stable friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

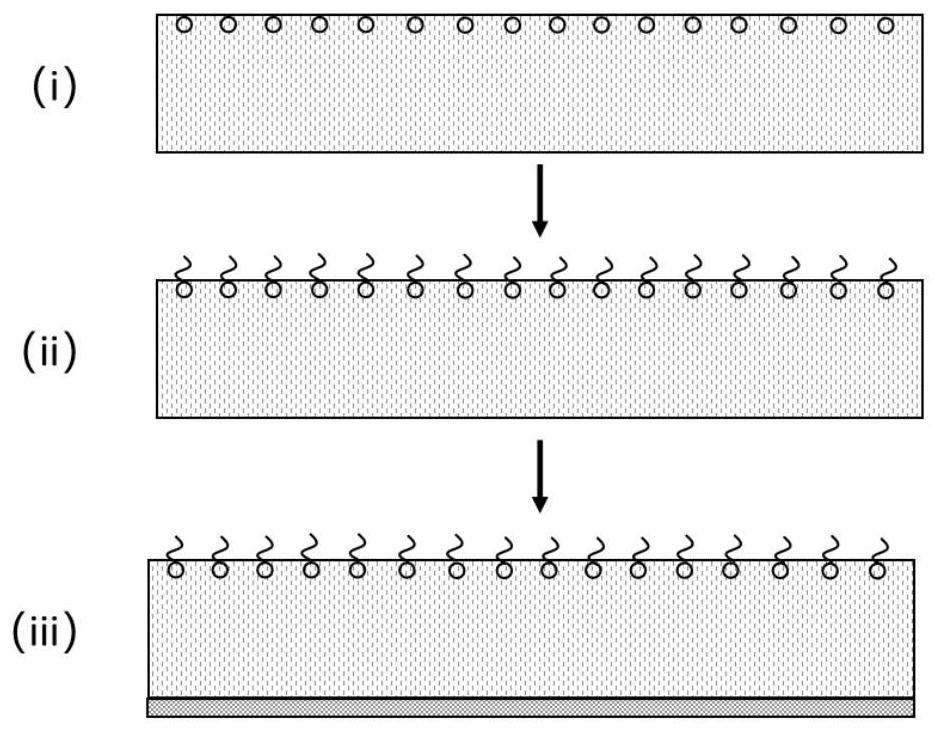

[0033] The present invention provides a preparation method of the above-mentioned transparent anti-fog patch modified by the polymer brush, comprising the following steps:

[0034] (1) soaking one side surface of the transparent polymer base film in a photoinitiator solution to obtain a transparent polymer base film modified with a photoinitiator on one side surface;

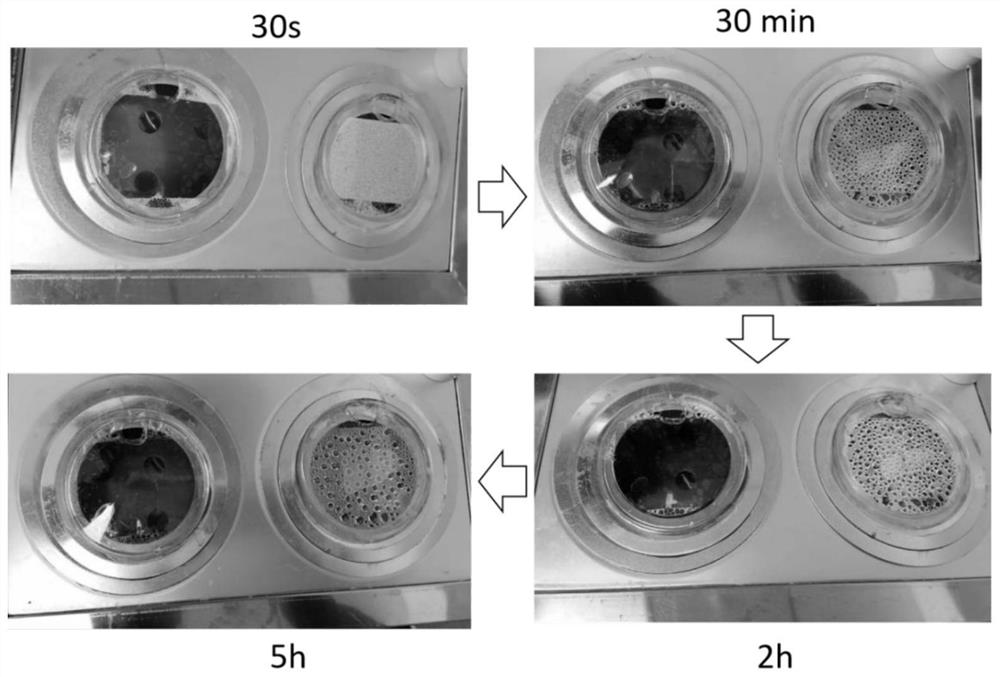

[0035] (2) Place the surface of the side surface of the transparent polymer base film modified with a photoinitiator in an aqueous solution of hydrophilic monomer, and carry out surface light-induced free radical grafting polymerization reaction under ultraviolet light. Surface modification hydrophilic polymer brush layer;

[0036] (3) Coating the other side of the transparent polymer base film with a hydrophilic polymer brush layer modified on one side with an organic adhesive to obtain a transparent anti-fog patch modified with a polymer brush.

[0037] In the invention, one side surface of the transparent po...

Embodiment 1

[0043] (1) In terms of mass parts, take by weighing 8192.5 parts of photoinitiator IRGACURE, 97.5 parts of isopropanol, and prepare a photoinitiator solution with a mass fraction of 2.5%; the upper surface of the PC base film with a thickness of 0.5mm is soaked in light After being in the initiator solution for 20 minutes, it was taken out and dried in the dark to obtain a PET base film with a photoinitiator modified on the upper surface.

[0044] (2) In terms of mass parts, weigh 5 parts of methacryloyl ethyl sulfobetaine (SBMA), 95 parts of deionized water, and prepare a monomer aqueous solution with a mass fraction of 5%; The upper surface of the PC base film was immersed in the aqueous monomer solution, and the surface was irradiated by a UV lamp with a power of 20mW for 30min to initiate free graft polymerization to obtain a transparent polymer substrate with a PSBMA hydrophilic polymer brush layer modified on the upper surface. membrane.

[0045] (3) Coat the lower surf...

Embodiment 2

[0048] (1) In terms of parts by mass, take photoinitiator IRGACURE 184 as 5 parts, 95 parts of ethanol, prepare a photoinitiator solution with a mass fraction of 5%; After the upper surface of the film was immersed in the photoinitiator solution for 30 minutes, it was taken out and dried in the dark to obtain a Sylgard 184 transparent silicone rubber base film with the photoinitiator modified on the upper surface.

[0049] (2) In terms of mass fraction, weigh 5 parts of 3-sulfopropyl methacrylate potassium salt (SPMK), 95 parts of deionized water, and prepare a monomer aqueous solution with a mass fraction of 5%; The upper surface of the Sylgard 184 type transparent silicone rubber base film was immersed in the above monomer aqueous solution, and the surface was irradiated by a UV lamp with a power of 100mW for 10min to initiate free graft polymerization to obtain a hydrophilic polymerization with PSBMA modified on the upper surface. The transparent polymer base film of the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com