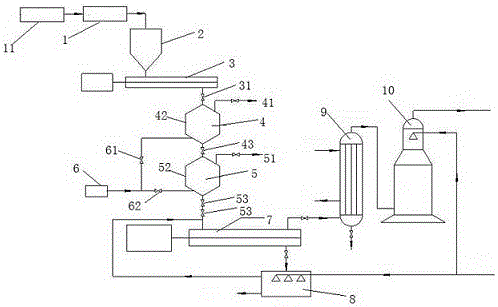

Electronic waste disposal system and method

A technology of e-waste and processing system, applied in the field of pyrolysis, which can solve the problems of limited pyrolysis degree, limited use of gas products, and non-pyrolysis of materials, so as to avoid coking of materials and efficiently treat e-waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

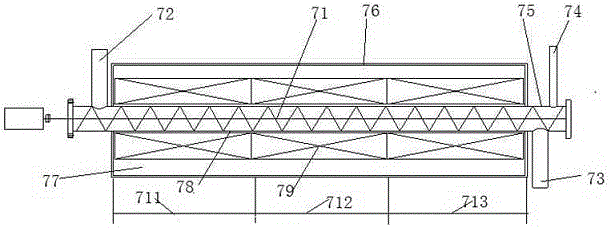

Method used

Image

Examples

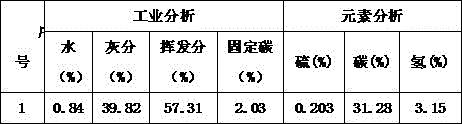

Embodiment 1

[0067] First, choose nitrogen as the inert gas, send nitrogen into the system, replace the feed system, reactor, cooling system and the pipes connecting each part, so that the whole system is in an inert atmosphere. When electronic waste is selected as printed circuit boards, it is crushed and sorted by the crushing and sorting device to obtain materials with a particle size below 30mm, which are sent to the feeding system by mechanical devices. The reactor heating unit was turned on to heat the reactor, and the temperature of the reactor was heated to 800°C. Open the cut-off valve in the intermediate storage tank of the feed system and the reactor, and feed the material into the reactor. The material undergoes pyrolysis reaction in the reactor, and the gas products produced are discharged from the top of the reactor end, and then enter the indirect heat exchanger and cooling tower for cooling, and the tar and non-condensable gas obtained are stored separately; the solid produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com