Method and device for intermittently removing heavy metals in wastewater

A heavy metal, intermittent technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve problems such as difficult solid-liquid separation, high equipment requirements, high price, etc., and achieve low operation and maintenance costs , The structure of the device is simple and the effect of easy industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

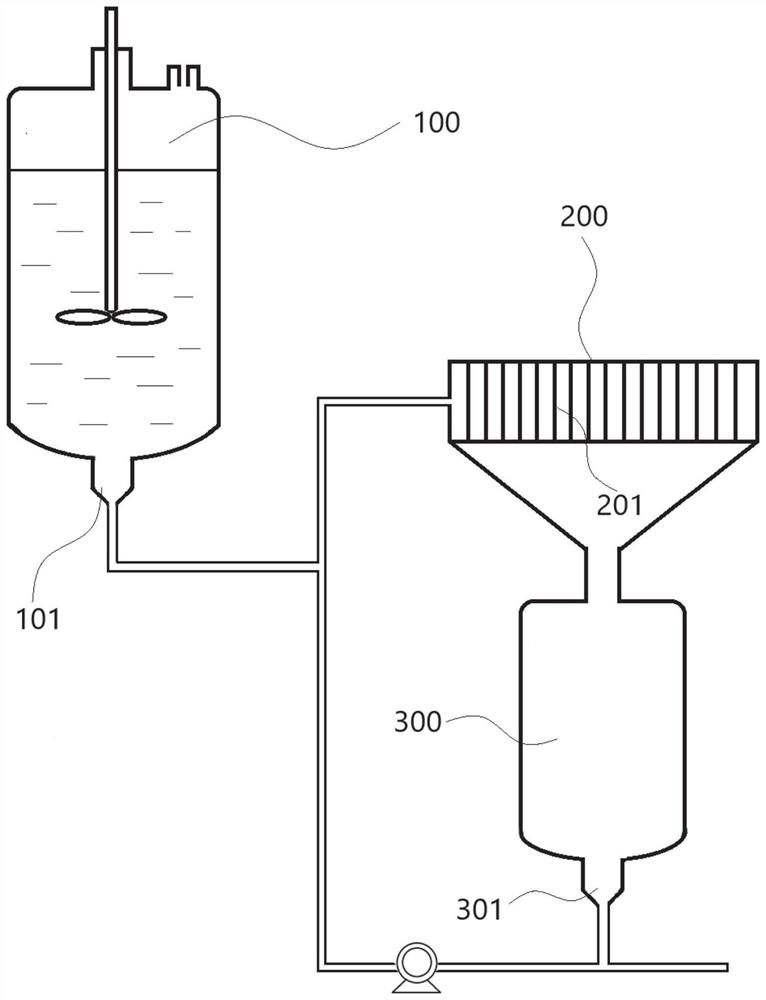

[0074] Add 40g of B-type silica gel (granular) into the adsorption tank 100, add 40L of aqueous solution with a copper ion concentration of 100mg / L to it, stir and adsorb for 1h, after the adsorption is completed, discharge the solid-liquid mixture to a plate and frame filter for solid-liquid separation , the hole diameter of the plate and frame porous metal support net used is 4-8mm, and the copper ion concentration of the filtrate is detected after filtration, and the concentration is 0.2mg / L, which reaches the emission standard (the emission standard is 0.5mg / L), and can be directly emission.

Embodiment 2

[0076] 40g of coconut shell charcoal powder (powder) is added in the adsorption tank 100, and 40L of cadmium ion concentration is added therein to be the aqueous solution of 100mg / L, stirring and adsorbing for 1h, after the adsorption finishes, the solid-liquid mixture is discharged to the plate-and-frame filter for solidification. Liquid-liquid separation, the hole diameter of the plate and frame porous metal support net used is 0.2-0.5mm, after filtering, the cadmium ion concentration of the filtrate is detected, the concentration is 0.3mg / L, which fails to meet the discharge standard (the discharge standard is 0.1mg / L ), the filtrate is sent back to the adsorption tank 100 with the return pump, and at the same time, 20g of coconut shell carbon powder is added again for adsorption again. After the second adsorption, the solid-liquid mixture is discharged to the plate and frame filter for solid-liquid separation. The used plate and frame The pore diameter of the porous metal s...

Embodiment 3

[0078] Add 40g of CH-97 ion exchange resin (granular) in the adsorption tank 100, add 40L of mercury ion concentration to it and be the aqueous solution of 100mg / L, stir and adsorb for 1h, after the adsorption finishes, the solid-liquid mixture is discharged to the plate and frame filter For solid-liquid separation, the pore size of the plate and frame porous metal support net used is 10-50 μm. After filtration, the mercury ion concentration of the filtrate is detected, and the concentration is 0.003mg / L, which meets the emission standard (the emission standard is 0.005mg / L), can be discharged directly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com