Method of treating magnesium alloy work-piece surface

A workpiece surface and treatment method technology, which is applied in the field of environment-friendly preparation of protective decorative film on the surface of magnesium alloy workpiece, can solve the problems of single color of the surface film layer, serious environmental pollution, weak decorative performance, etc., and achieve excellent durability and processing The process is simple and the effect of environmental protection is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

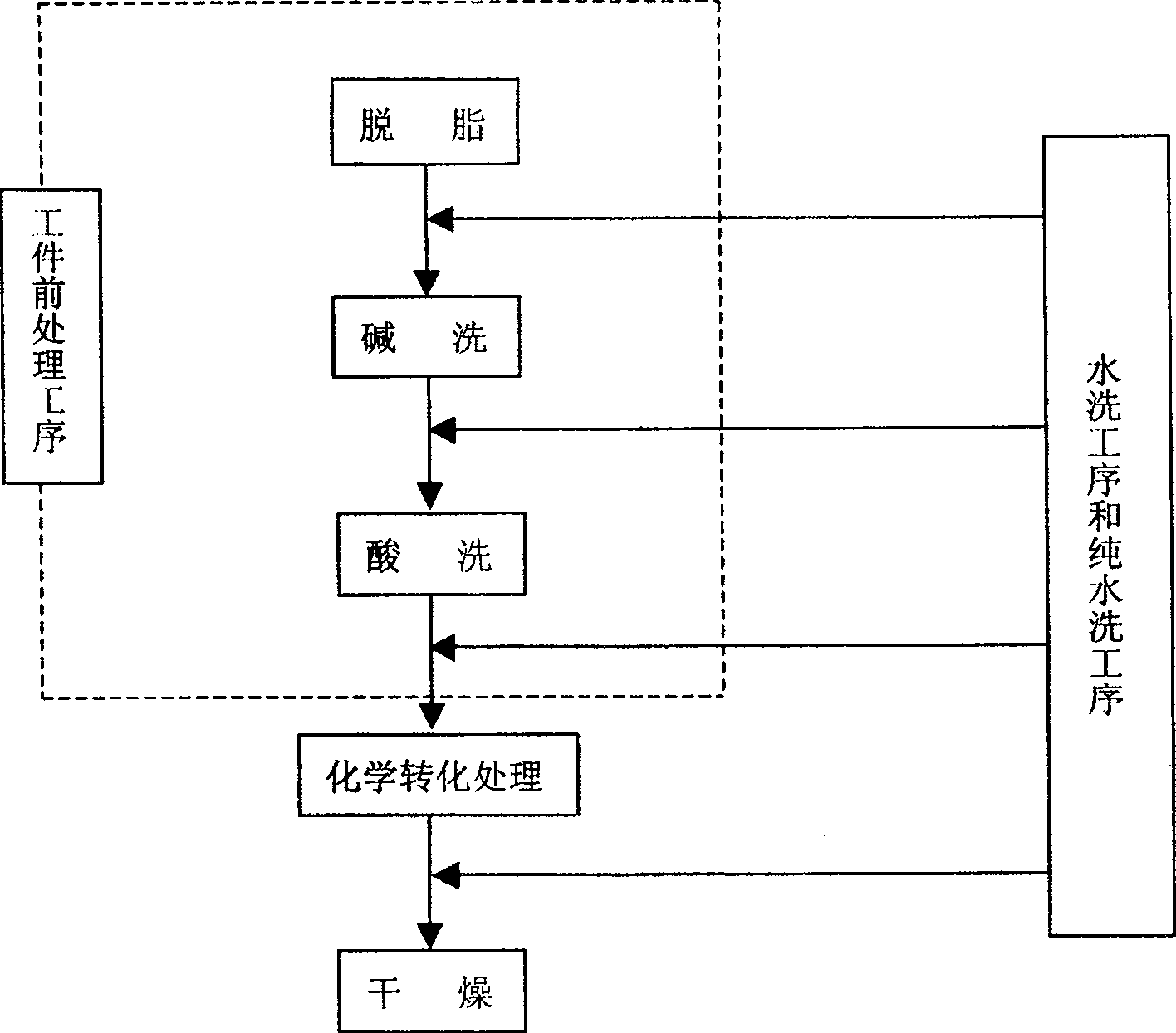

Method used

Image

Examples

Embodiment 1

[0036] Conversion liquid composition: sodium aluminate [Na 2 MoO 4 2H 2 O] 48g / L;

[0037] Lithium nitrate [LiNO 3 ] 5g / L.

[0038] The pH value of the conversion solution was 4.

[0039] Treatment conditions: temperature 80°C, time 5 minutes.

[0040] Film quality inspection results: The film layer is light purple, continuous, and free of defects. The spot test result is 76 seconds, and the paint film bonding force is 100%. After the workpiece is placed for 425 days, there is no change in color, and there is no peeling off or corrosion of the film layer.

Embodiment 2

[0042] Conversion liquid composition: sodium molybdate [Na 2 MoO 4 2H 2 O] 150g / L;

[0043] Sodium nitrate [NaNO 3 ], lithium sulfate [Li 2 SO 4 ·H 2 O] 20g / L (converted to LiNO 3 content).

[0044] The pH value of the conversion solution was 3.

[0045] Treatment conditions: temperature 60°C, time 15 minutes.

[0046] Film quality inspection results: the film is brown, continuous, and has no defects. The spot test result is 142 seconds, and the paint film bonding force is 100%. After the workpiece is placed for 425 days, there is no change in color, no peeling off and no corrosion of the film.

Embodiment 3

[0048] Conversion liquid composition: zirconium sulfate [ZrSO 4 4H 2 O] 5g / L (converted to Na 2 MoO 4 2H 2 O content);

[0049] Lithium sulfate [Li 2 SO 4 ·H 2 O] 1.5g / L (converted to LiNO 3 content).

[0050] The pH value of the conversion solution was 5.

[0051] Treatment conditions: temperature 40°C, time 10 minutes.

[0052] Film quality inspection results: the film is silver-gray, continuous, and has no defects. The spot test result is 83 seconds, and the paint film bonding force is 100%. After the workpiece is placed for 425 days, there is no change in color, no peeling off and no corrosion of the film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com