Production method of plastic packaging bag

A production method and packaging bag technology, which is applied in the field of plastic packaging bags, can solve the problems of poor toughness and poor tensile performance, and achieve the effects of enhanced tensile strength, not easy to break, and good stretching and toughening effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

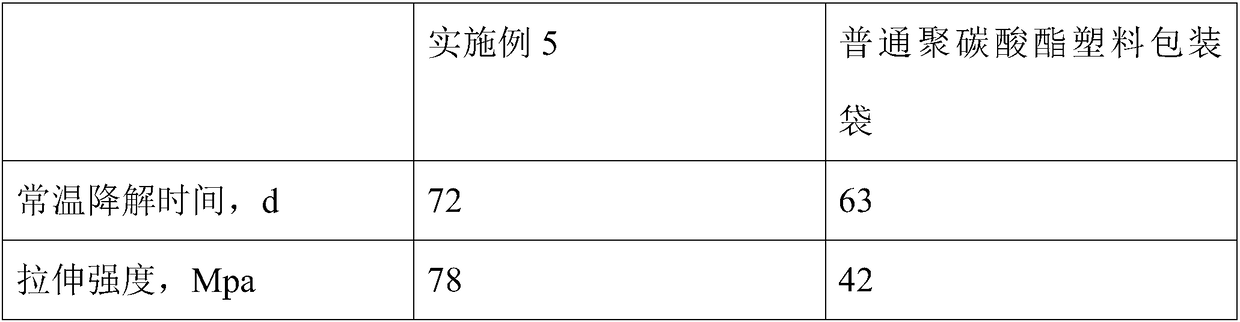

Examples

Embodiment 1

[0020] A production method of a plastic packaging bag, comprising the following steps:

[0021] S1, mix 12kg magnesium hydroxide and 1kg sodium oxalate, grind for 1h, the grinding temperature is 150°C, the grinding pressure is 0.04Mpa, add 2kg polyethylene glycol acrylate, 2kg epichlorohydrin, 80kg cyclohexanone and mix well, Add 0.12kg tetrabutylammonium fluoride, 3kg potassium hydroxide and stir for 30min, the stirring temperature is 90 ℃, wash, precipitate, add 120kg water, 2kg sodium lauryl sulfate and stir for 10min, the stirring speed is 1000r / min, filter, Washing, drying at 90°C to constant weight, dispersing and grinding to obtain the first material;

[0022] S2, stirring 67kg polycarbonate, 12kg etherified starch, 1kg octadecyl trimethyl ammonium bromide, 10kg montmorillonite, 12kg zeolite powder, 0.1kg antioxidant, stirring speed is 900r / min, obtains the second material;

[0023] S3, calcine 30kg kaolin for 15min, the calcination temperature is 600 ℃, pulverize, ad...

Embodiment 2

[0025] A production method of a plastic packaging bag, comprising the following steps:

[0026] S1, mix 18kg magnesium hydroxide and 0.4kg sodium oxalate, grind for 2h, the grinding temperature is 120°C, the grinding pressure is 0.08Mpa, add 1kg polyethylene glycol acrylate, 10kg epichlorohydrin, 60kg cyclohexanone and mix well , add 0.18kg tetrabutylammonium fluoride, 1kg potassium hydroxide and stir for 40min, the stirring temperature is 70 ℃, wash, precipitate, add 200kg water, 1kg sodium lauryl sulfate and stir for 14min, the stirring speed is 800r / min, filter , washed, dried at 98°C to constant weight, dispersed and ground to obtain the first material;

[0027] S2, stir 35kg polycarbonate, 24kg etherified starch, 0.2kg octadecyl trimethyl ammonium bromide, 20kg montmorillonite, 4kg zeolite powder, 0.4kg antioxidant, and the stirring speed is 500r / min, get the second material;

[0028] S3, calcine 50kg kaolin for 10min, the calcination temperature is 700 ℃, pulverize, ad...

Embodiment 3

[0030] A production method of a plastic packaging bag, comprising the following steps:

[0031] S1, mix 14kg magnesium hydroxide and 0.8kg sodium oxalate, grind for 1.3h, the grinding temperature is 140°C, the grinding pressure is 0.05Mpa, add 1.7kg polyethylene glycol acrylate, 4kg epichlorohydrin, 75kg cyclohexanone Mix well, add 0.14kg of tetrabutylammonium fluoride, 2.5kg of potassium hydroxide and stir for 33min, the stirring temperature is 85 ℃, wash, precipitate, add 140kg of water, 1.7kg of sodium lauryl sulfate and stir for 11min, the stirring speed is 950r / min, filter, wash, dry at 92°C to constant weight, disperse and grind to obtain the first material;

[0032] S2, stir 60kg polycarbonate, 16kg etherified starch, 0.8kg octadecyl trimethyl ammonium bromide, 12kg montmorillonite, 10kg zeolite powder, 0.2kg antioxidant, and the stirring speed is 800r / min, get the second material;

[0033] S3, calcine 35kg kaolin for 14min, the calcination temperature is 640 ℃, pulv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com