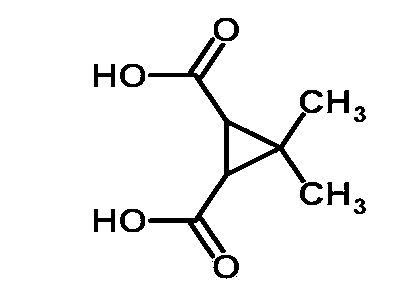

Preparation method of 3,3-dimethyl-1,2-cyclopropane dicarboxylic acid

A technology of cyclopropanedicarboxylic acid and dimethyl, which is applied in the field of chemical synthesis, can solve the problems of high production cost, achieve the effects of reducing production cost, broadening the application range, and shortening the reaction route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 100 grams of 3-carene, 5 grams of cetyl sodium sulfate and 350 grams of water to the reaction kettle in turn, gradually add 600 grams of potassium permanganate to the reaction kettle, and finish adding in 3 hours, stir evenly, and control the reaction temperature 35°C, react for 5 hours; filter, collect the filtrate and filter residue respectively, the filtrate is set aside, add water to the filter residue and wash 8 times, collect the washing liquid, combine the filtrate and washing liquid to obtain a mixed solution, adjust the pH value of the mixed solution to 10, and add to the mixed solution Add 1 / 4 volume of benzene to the solution to extract 3 times, collect the aqueous layer solution, add 0.1mol / L hydrochloric acid solution to the aqueous layer solution to adjust the pH of the solution to 2, heat and concentrate at 90°C, filter, wash with water, and dry , That is, 3,3-dimethyl-1,2-cyclopropane dicarboxylic acid.

Embodiment 2

[0023] Add 1 kilogram of 3-carene, 50 grams of cetyl sodium sulfate and 10 kilograms of water to the reaction kettle in turn, gradually add 2.5 kilograms of potassium permanganate to the reaction kettle, finish adding in 3 hours, stir evenly, and control the reaction temperature at 20°C, react for 10 hours; filter, collect the filtrate and filter residue respectively, the filtrate is set aside, add water to the filter residue and wash 8 times, collect the washing liquid, combine the filtrate and washing liquid to obtain a mixed solution, adjust the pH value of the mixed solution to 10, and add to the mixed solution Add 1 / 4 volume of benzene to the solution to extract 5 times, collect the aqueous layer solution, add 0.1mol / L hydrochloric acid solution to the aqueous layer solution to adjust the pH to 2, heat and concentrate at 90°C, filter, wash with water, and dry. That is, 3,3-dimethyl-1,2-cyclopropane dicarboxylic acid.

Embodiment 3

[0025] Add 10 kilograms of 3-carene, 100 grams of cetyl sodium sulfate and 70 kilograms of water to the reaction kettle in turn, gradually add 90 kilograms of potassium permanganate to the reaction kettle, and finish adding in 3 hours, stir evenly, and control the reaction temperature 5°C, reacted for 15 hours; filtered, collected the filtrate and filter residue respectively, the filtrate was set aside, the filter residue was washed with water 8 times, the washing liquid was collected, the filtrate and the washing liquid were combined to obtain a mixed solution, and the pH value of the mixed solution was adjusted to 10. Add 1 / 4 volume of benzene to the solution to extract 4 times, collect the aqueous layer solution, add 0.1mol / L hydrochloric acid solution to the aqueous layer solution to adjust the pH of the solution to 2, heat and concentrate at 90°C, filter, wash with water, and dry , That is, 3,3-dimethyl-1,2-cyclopropane dicarboxylic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com