Double-plating steel belt and plating process

A technology of electroplating process and coated steel, which is applied in the field of electroplating of punched steel strip and perforated steel strip, which can solve the problems of low corrosion resistance and high cost, and achieve the effect of simple operation and simple process maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0032] One embodiment of the present invention comprises the following steps:

[0033] (1) Degreasing: All kinds of acidic or alkaline degreasing solutions can be used, the purpose is to remove the oil on the surface of the steel strip.

[0034] (2) Wash with water;

[0035] (3) Cathodic and anode combined electrolysis to remove oil;

[0036] (4) Wash with water;

[0037] (5) Acid etching; the purpose is to remove the rust and scale on the surface of the plated parts;

[0038] (6) Wash with water;

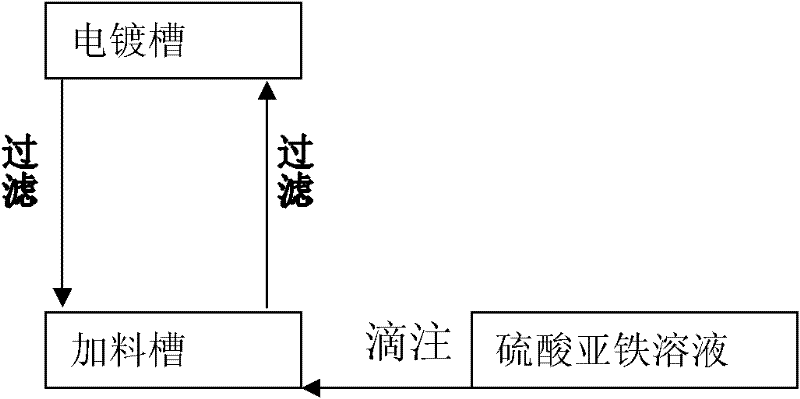

[0039] (7) Electroplating nickel-iron alloy: the formula of electroplating solution is NiSO 4 ·7H 2 O 220~250g / L; H 3 BO 3 30~40g / L; NaCl0~15g / L, FeSO 4 ·7H 2 O 25 ~ 35g / L, sodium lauryl sulfate 0.1 ~ 0.3g / L, a small amount of stabilizer (the stabilizer used here generally uses ascorbic acid 1 ~ 2g / L, commercially available commercial stabilizers can also be used, such as Guangzhou BH stabilizer produced by Erqing) temperature 50~70℃, current density 2~10A / dm 2 , The tap...

Embodiment 1

[0050] Embodiment 1: a perforated steel strip with a thickness of 0.1 mm and a width of 23 mm

[0051] (1) Degreasing: All kinds of acidic or alkaline degreasing solutions can be used, the purpose is to remove the oil on the surface of the steel strip.

[0052] (2) Wash with water;

[0053] (3) Cathodic and anode combined electrolysis to remove oil;

[0054] (4) Wash with water;

[0055] (5) Acid etching;

[0056] (6) Wash with water;

[0057] (7) Electroplating nickel-iron alloy: the formula of electroplating solution is NiSO 4 ·7H 2 O 220g / L; H 3 BO 330g / L; NaCl 12g / L, FeSO 4 ·7H 2 O 28g / L, sodium lauryl sulfate 0.1g / L, BH stabilizer 18ml / L, temperature 55°C, current density 5A / dm 2 , plating time 3min.

[0058] Nickel-iron alloy thickness 2.3μm.

[0059] (8) Wash with water

[0060] (9) Electroplating nickel: general electroplating nickel formula and process electroplating nickel 0.5 ~ 2μm

[0061] (10) Wash with water

[0062] (11) Neutralization: pass the s...

Embodiment 2

[0067] Embodiment 2: electroplating thickness is 0.1mm, the punching steel strip that width is 180mm

[0068] (1) Degreasing: All kinds of acidic or alkaline degreasing solutions can be used, the purpose is to remove the oil on the surface of the steel strip.

[0069] (2) Wash with water;

[0070] (3) Cathodic and anode combined electrolysis to remove oil;

[0071] (4) Wash with water;

[0072] (5) Acid etching;

[0073] (6) Wash with water;

[0074] (7) Electroplating nickel-iron alloy: the formula of electroplating solution is NiSO 4 ·7H 2 O240g / L; H 3 BO 3 32g / L; NaCl 14g / L, FeSO 4 7H 2 O31g / L, sodium lauryl sulfate 0.2g / L, ascorbic acid 1.5g / L) temperature 65°C, current density 8A / dm 2 , plating time 2min.

[0075] The nickel-iron alloy thickness is 3.1 μm.

[0076] (8) Wash with water

[0077] (9) Electroplating nickel: general electroplating nickel formula and process electroplating nickel 0.5 ~ 2μm

[0078] (10) Wash with water

[0079] (11) Neutralizatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com