Double-plating steel belt and plating process

An electroplating process and coating steel technology, which is applied in the field of double-coated steel strip and electroplating process, can solve the problems of high cost and low corrosion resistance, and achieve the effect of simple operation and simple process maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0032] One embodiment of the present invention comprises the following steps:

[0033] (1) Degreasing: All kinds of acidic or alkaline degreasing solutions can be used, the purpose is to remove the oil on the surface of the steel strip.

[0034] (2) Wash with water;

[0035] (3) Cathodic and anode combined electrolysis to remove oil;

[0036] (4) Wash with water;

[0037] (5) Acid etching; the purpose is to remove the rust and scale on the surface of the plated parts;

[0038] (6) Wash with water;

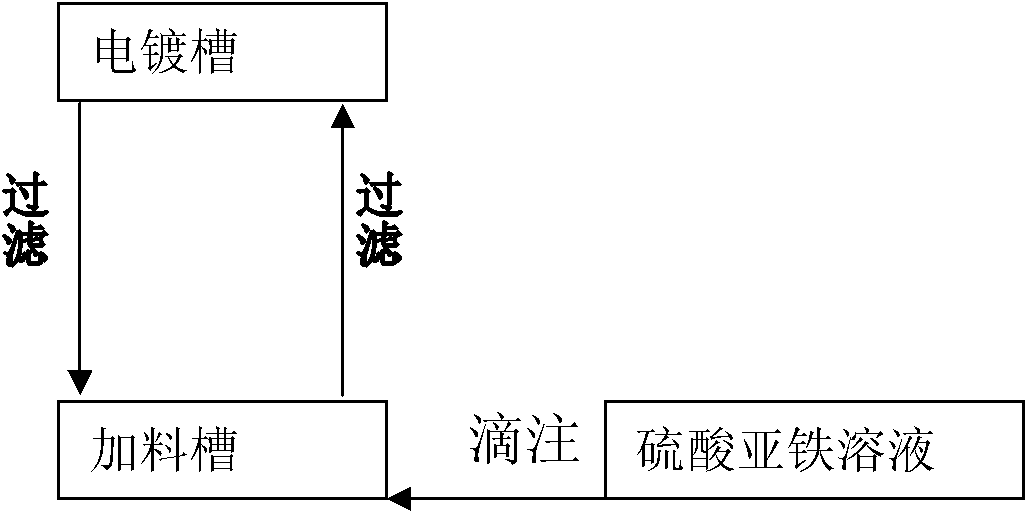

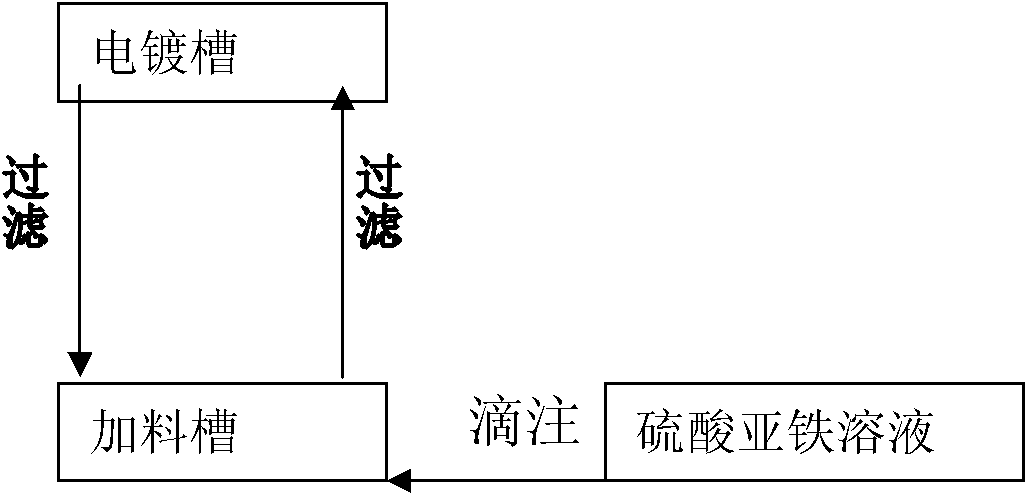

[0039] (7) Electroplating nickel-iron alloy: the formula of electroplating solution is NiSO 4 ·7H 2 O 220~250g / L; H 3 BO 3 30~40g / L; NaCl0~15g / L, FeSO 4 ·7H 2 O 25 ~ 35g / L, sodium lauryl sulfate 0.1 ~ 0.3g / L, a small amount of stabilizer (the stabilizer used here generally uses ascorbic acid 1 ~ 2g / L, commercially available commercial stabilizers can also be used, such as Guangzhou BH stabilizer produced by Erqing) temperature 50~70℃, current density 2~10A / dm 2 , The tap...

Embodiment 1

[0050] Embodiment 1: a perforated steel strip with a thickness of 0.1 mm and a width of 23 mm

[0051] (1) Degreasing: All kinds of acidic or alkaline degreasing solutions can be used, the purpose is to remove the oil on the surface of the steel strip.

[0052] (2) Wash with water;

[0053] (3) Cathodic and anode combined electrolysis to remove oil;

[0054] (4) Wash with water;

[0055] (5) Acid etching;

[0056] (6) Wash with water;

[0057] (7) Electroplating nickel-iron alloy: the formula of electroplating solution is NiSO 4 ·7H 2 O 220g / L; H 3 BO 330g / L; NaCl 12g / L, FeSO 4 ·7H 2 O 28g / L, sodium lauryl sulfate 0.1g / L, BH stabilizer 18ml / L, temperature 55°C, current density 5A / dm 2 , plating time 3min.

[0058] Nickel-iron alloy thickness 2.3μm.

[0059] (8) Wash with water

[0060] (9) Electroplating nickel: general electroplating nickel formula and process electroplating nickel 0.5 ~ 2μm

[0061] (10) Wash with water

[0062] (11) Neutralization: pass the s...

Embodiment 2

[0067] Embodiment 2: electroplating thickness is 0.1mm, the punching steel strip that width is 180mm

[0068] (1) Degreasing: All kinds of acidic or alkaline degreasing solutions can be used, the purpose is to remove the oil on the surface of the steel strip.

[0069] (2) Wash with water;

[0070] (3) Cathodic and anode combined electrolysis to remove oil;

[0071] (4) Wash with water;

[0072] (5) Acid etching;

[0073] (6) Wash with water;

[0074] (7) Electroplating nickel-iron alloy: the formula of electroplating solution is NiSO 4 ·7H 2 O240g / L; H 3 BO 3 32g / L; NaCl 14g / L, FeSO 4 7H 2 O31g / L, sodium lauryl sulfate 0.2g / L, ascorbic acid 1.5g / L) temperature 65°C, current density 8A / dm 2 , plating time 2min.

[0075] The nickel-iron alloy thickness is 3.1 μm.

[0076] (8) Wash with water

[0077] (9) Electroplating nickel: general electroplating nickel formula and process electroplating nickel 0.5 ~ 2μm

[0078] (10) Wash with water

[0079] (11) Neutralizatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com