Sealing-in method for packaging outer shell with aluminum silicon carbide

A silicon carbide sealing and shell technology, applied in welding equipment, electrical components, circuits, etc., can solve problems such as difficulty in sealing SiC composite materials

Inactive Publication Date: 2010-08-11

UNIV OF SCI & TECH BEIJING

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

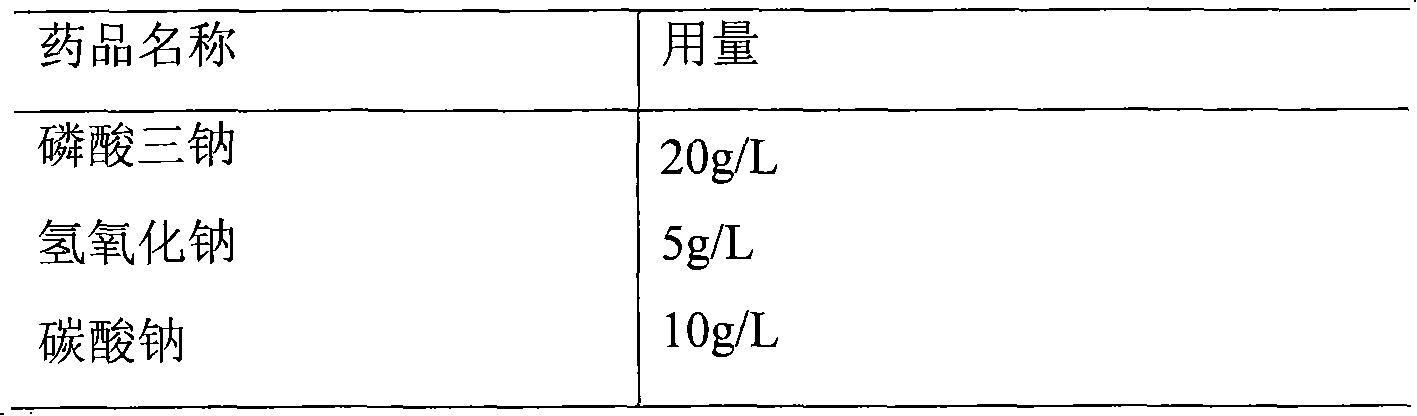

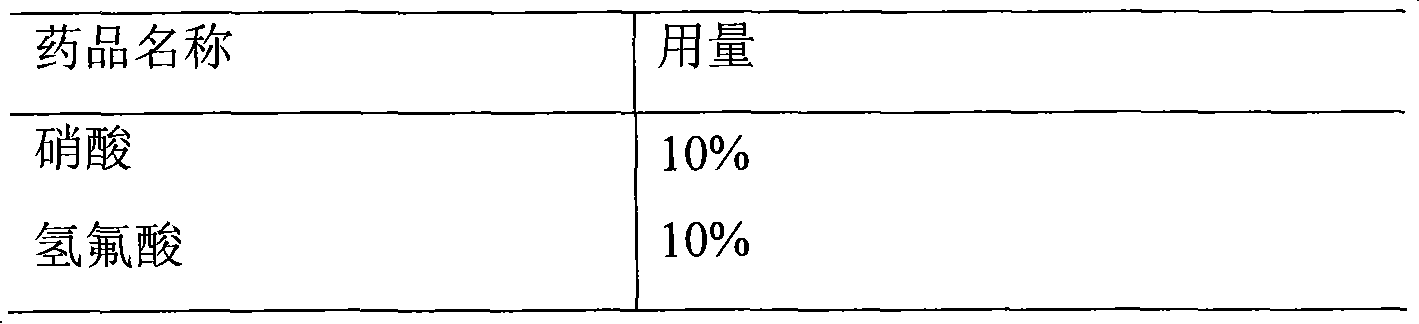

The purpose of the invention is to replace the traditional Au-Sn alloy with Sn-Ag-Ni solder, while solving the problem of SiC p / Al composite materials are difficult to seal, and SiC is widely used for metal shell factories p / Al composites pave the way as shell and cover materials

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

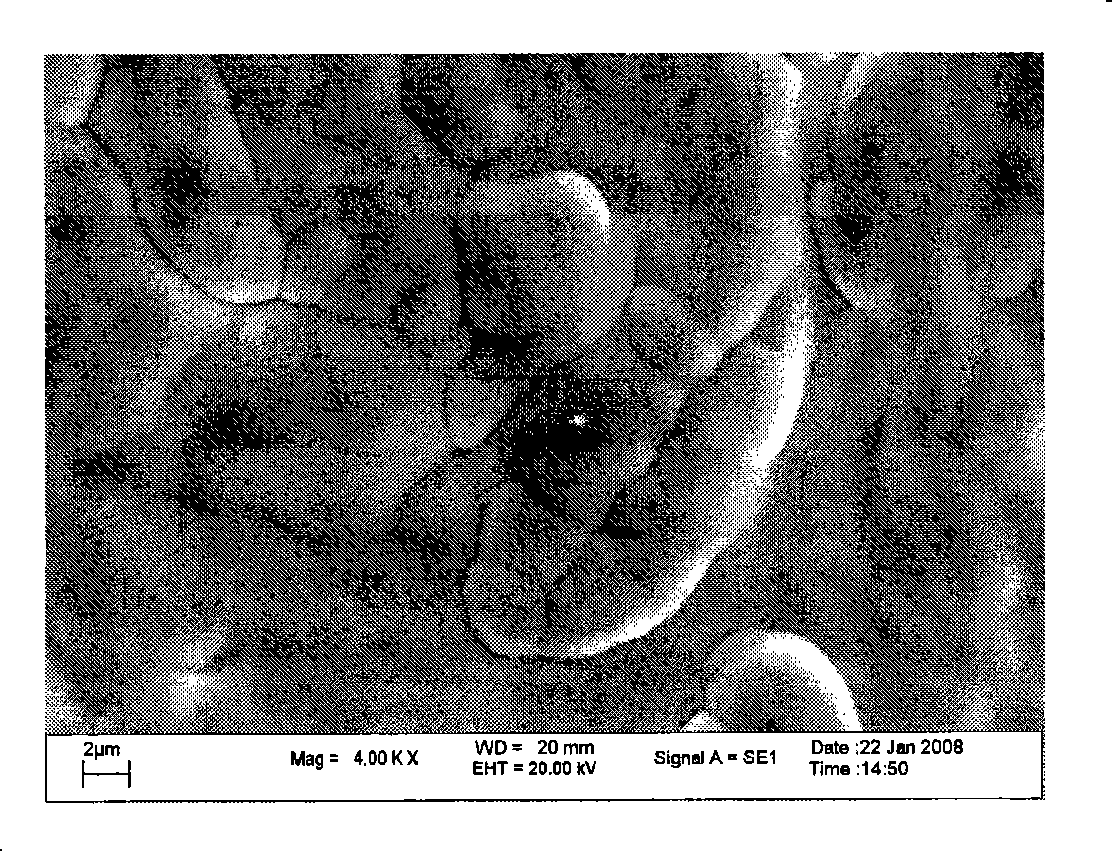

The invention pertains to the field of metallic material and provides a method for sealing a sealed cover when SiCp / Al composite material is used as an encapsulation encloser and a cover plate. The method is applicable to the encapsulation enclosers of micro-electronics appliances such as a hybrid integrated circuit, a millimeter wave / micron wave integrated circuit and a multichip module in micro-electronics encapsulation. Double-layer plating is carried out on the surface of the SiCp / Al composite material; the SiCp / Al composite material encloser with a surface coating and the cover plate arewelded together by Sn based solder. The method not only reduces production cost greatly, but also solves the problem of difficulty in sealing and connection of the SiCp / Al composite material, thus paving the way for widely using the SiCp / Al composite material as the material of enclosers and cover plates by related metal encloser factories.

Description

technical field The invention belongs to the field of metal materials and provides an aluminum silicon carbide composite material (SiC p / Al) is used as a hermetic capping method when encapsulating the casing and cover. It is suitable for packaging shells of microelectronic devices such as hybrid integrated circuits, millimeter wave / micron wave integrated circuits, and multi-chip components in microelectronic packaging. Background technique Metal packaging is a form of electronic packaging that uses metal as the shell or base, the chip is directly or through the substrate mounted on the shell or base, and the lead wire passes through the metal shell or base, mostly using glass-metal sealing technology. It is widely used in the packaging of hybrid circuits, mainly military and customized special hermetic packaging, and has been widely used in many fields, especially in military and aerospace fields. Although the traditional packaging shell material Kovar has a suitable CTE,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23K1/008B23K1/20H01L21/48

Inventor 吴茂何新波曲选辉孟菲菲任淑彬

Owner UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com