Sealing-in method for packaging outer shell with aluminum silicon carbide

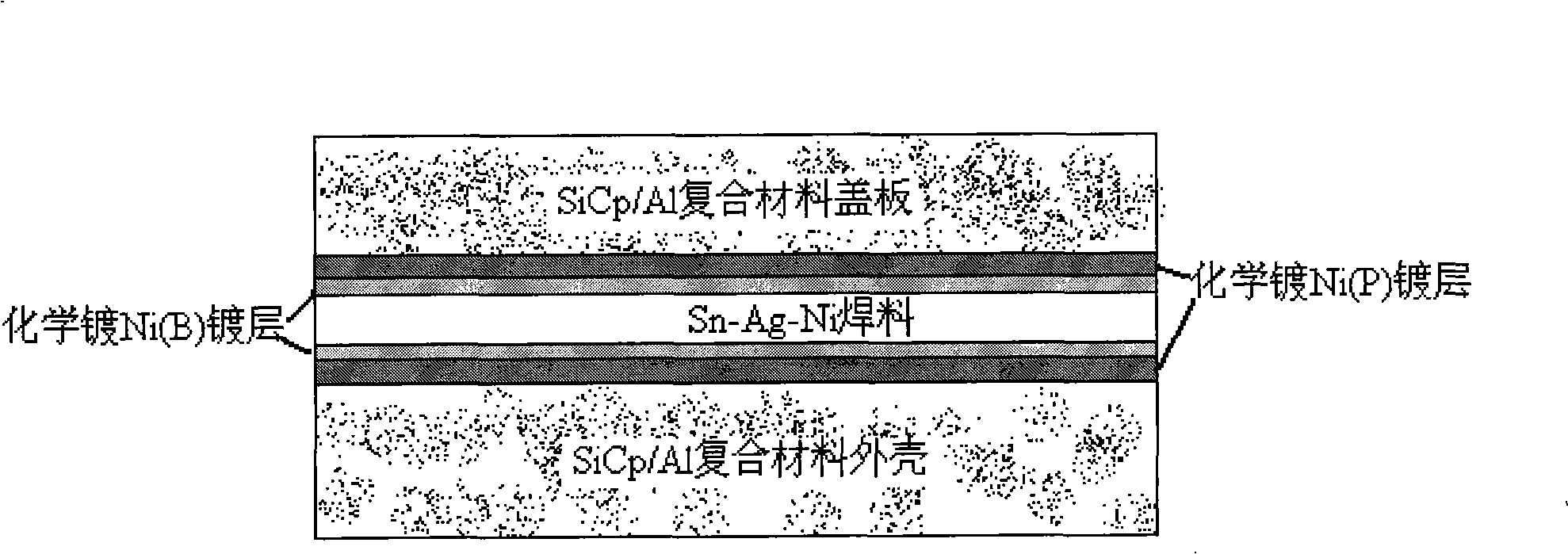

A silicon carbide sealing and shell technology, applied in welding equipment, electrical components, circuits, etc., can solve problems such as difficult sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below, the present invention will be further described with examples.

[0025] (1) In SiC p The specific process flow of electroless plating Ni(P) / Ni(B) on the surface of / Al composite material can be shown in the following table:

[0026] Mechanical polishing→chemical degreasing→deionized water washing→acid etching→deionized water washing→sensitization→deionized water washing→activation→deionized water washing→electroless Ni(P)→electroless Ni(B).

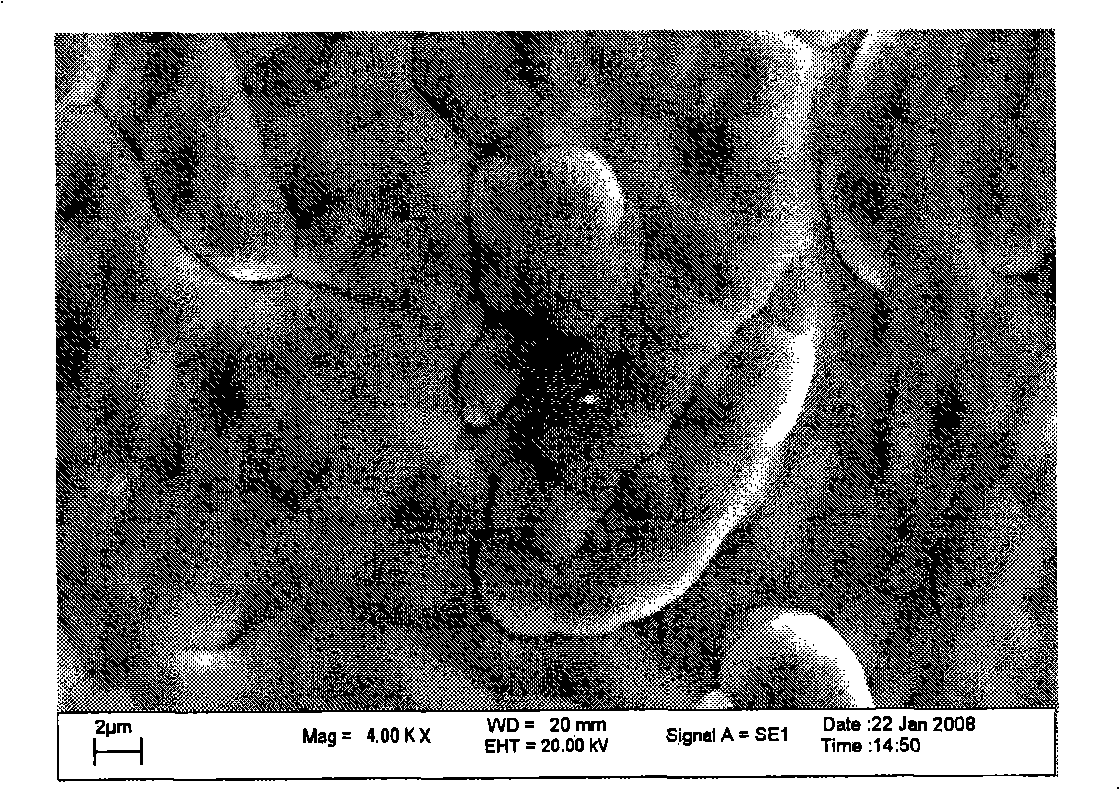

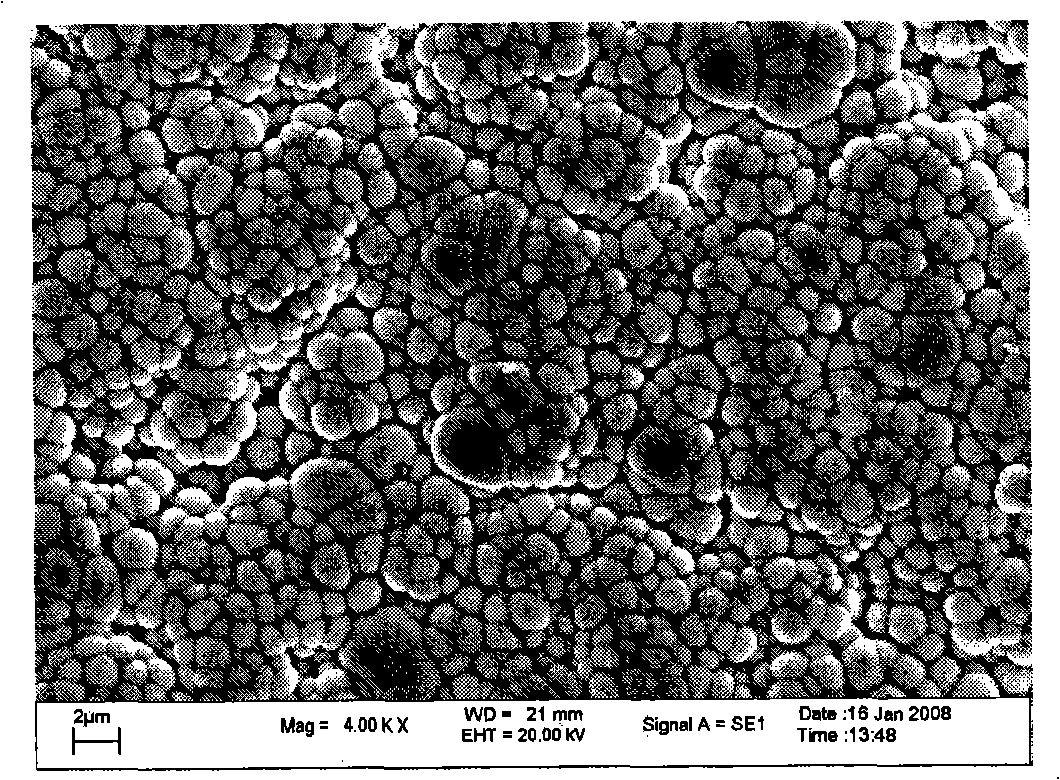

[0027] Wherein the solution formula of each step and process condition are as shown in table 1 to table 5, after successfully electroless plating Ni (P) alloy, shell is carried out electroless plating Ni (B) alloy immediately, its plating solution formula and process parameter are as table 6. figure 2 It is the surface morphology of the coating after electroless Ni(P) and Ni(B) plating.

[0028] Table 1 Chemical degreasing formula (room temperature, 30s)

[0029]

[0030] Table 2 acid etching formula (room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com