Grinding method of edge of milling cutter and tool

A technology for milling cutters and blades, which is applied in the field of grinding devices for milling cutters. It can solve the problems of small blade size, increased operating costs, and waste of resources, and achieves the effects of precise and efficient grinding, easy production and maintenance, and resource saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

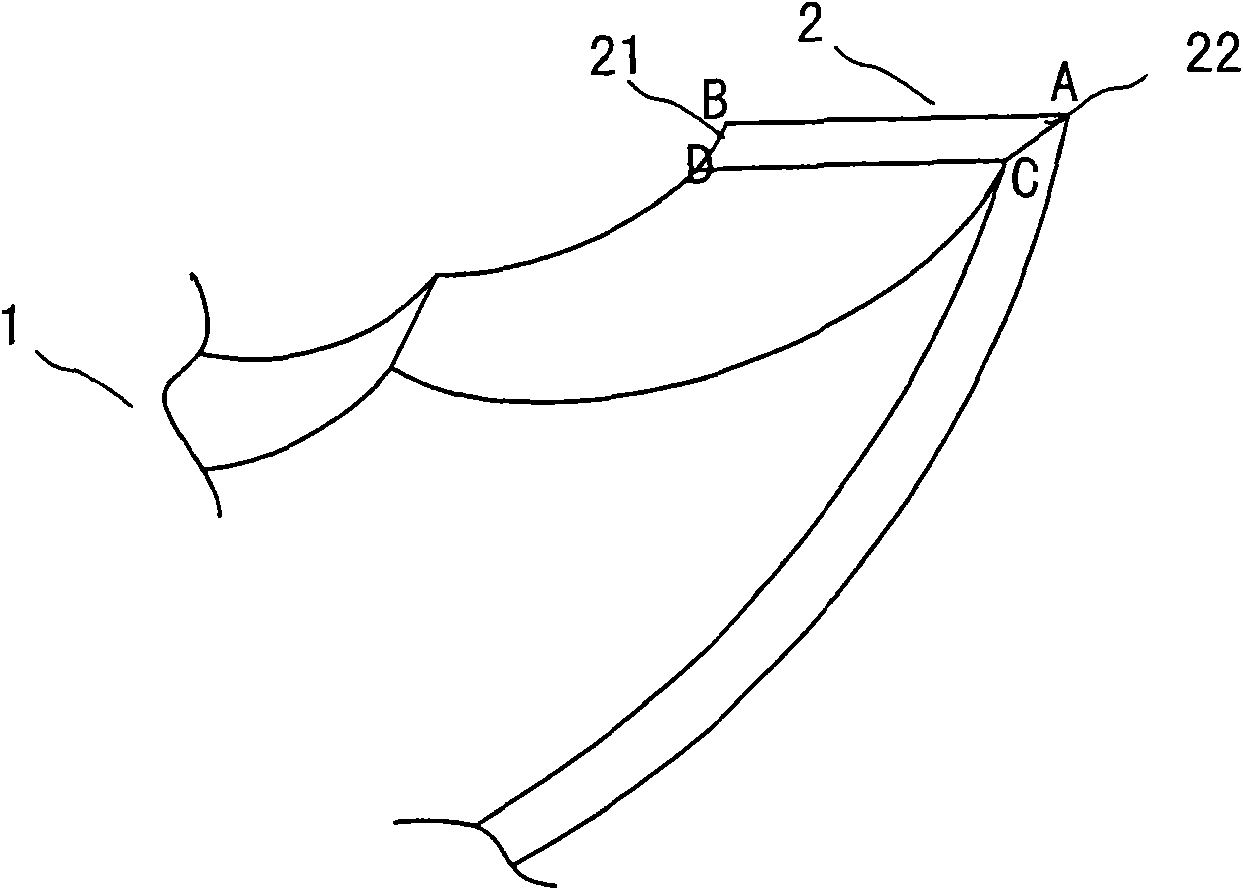

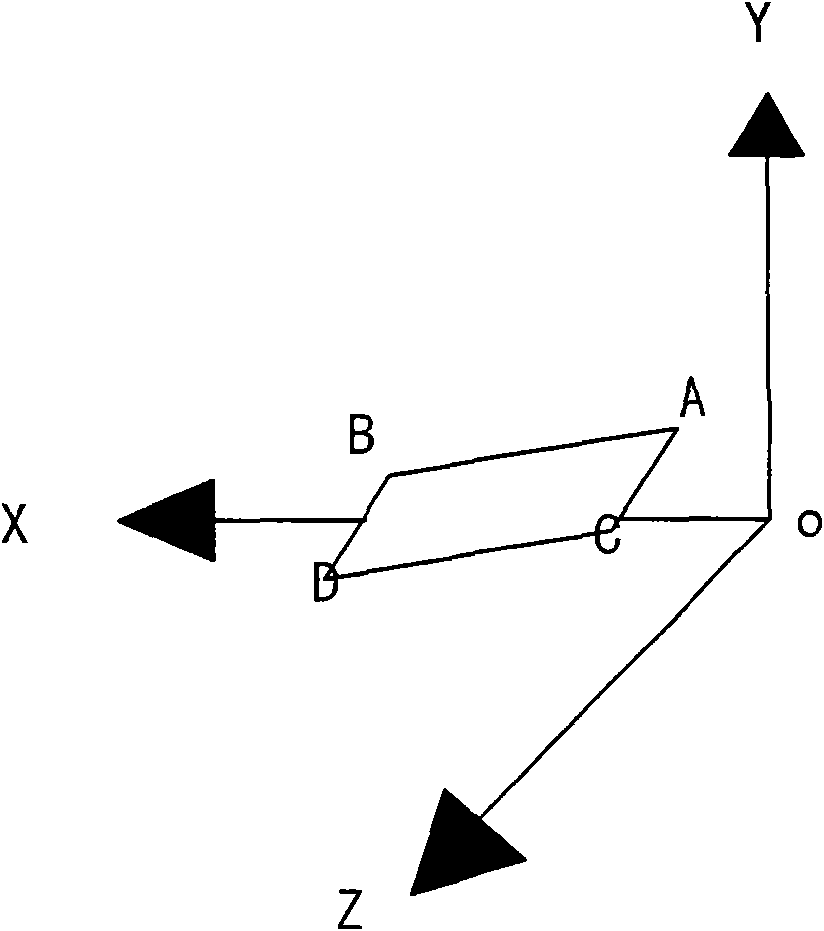

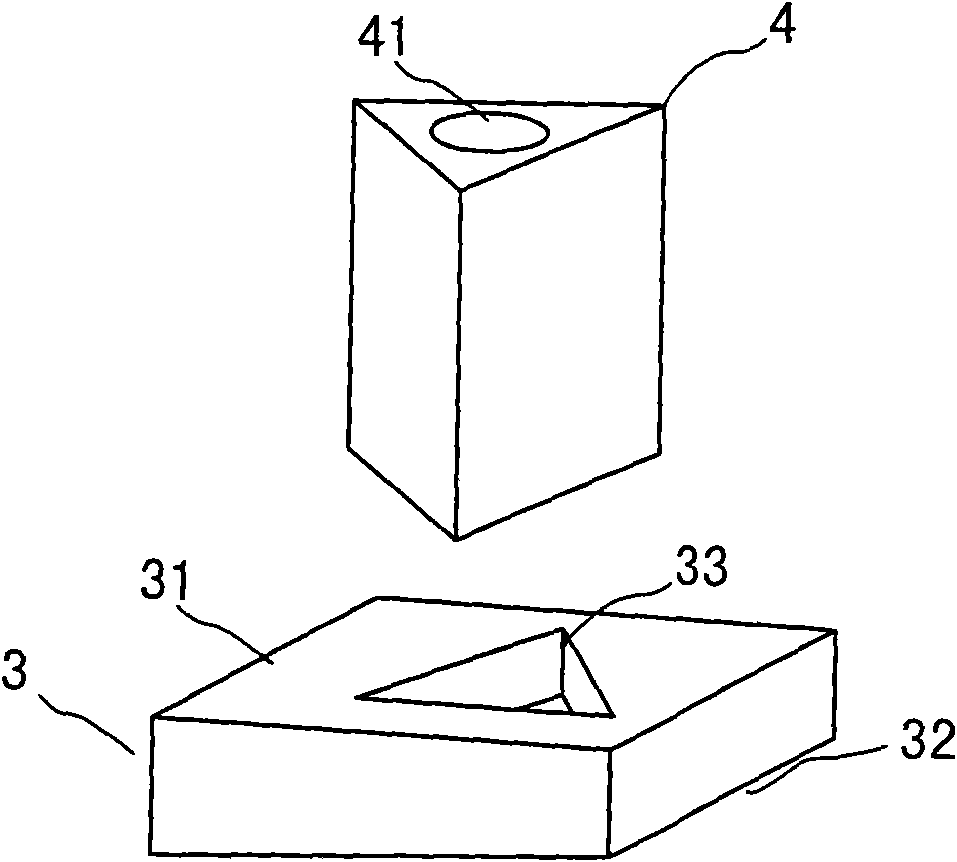

[0029] Such as Figure 1~5 As shown, the milling cutter edge grinding method is mainly applied to the grinding of milling cutters with inclined edge faces. The milling cutter is an end mill, and its head has three symmetrically distributed blades, and the adjacent blades are staggered. 120°, and each blade surface is a two-dimensional rectangular inclined surface. The blade tip A is at the highest point, and the heights of the other end points B, C, and D of the blade surface decrease successively. Due to the small blade size, if a conventional grinding wheel is used directly Grinding it with abrasive tools is extremely difficult to operate and cannot achieve a certain accuracy. For this reason, in this embodiment, the blade surface is adjusted by means of a jig as described below so that the blade surface can be ground with an ordinary grinding wheel. This jig comprises a base 3 and a support 4, and the base is a member with an isosceles trapezoidal cross-section, and the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com