Cigarette tipping paper laser boring method and apparatus

A cigarette tipping paper and laser drilling technology, which is applied to laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of not providing a realization method, etc., and achieve high laser energy utilization rate, good product quality, and processing efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The invention provides two laser drilling methods for cigarette tipping paper, which are a rotating polygonal prism type drilling method and a galvanometer type drilling method. The invention also provides two devices for realizing the method.

[0043] The present invention will be further described below in conjunction with embodiments and drawings.

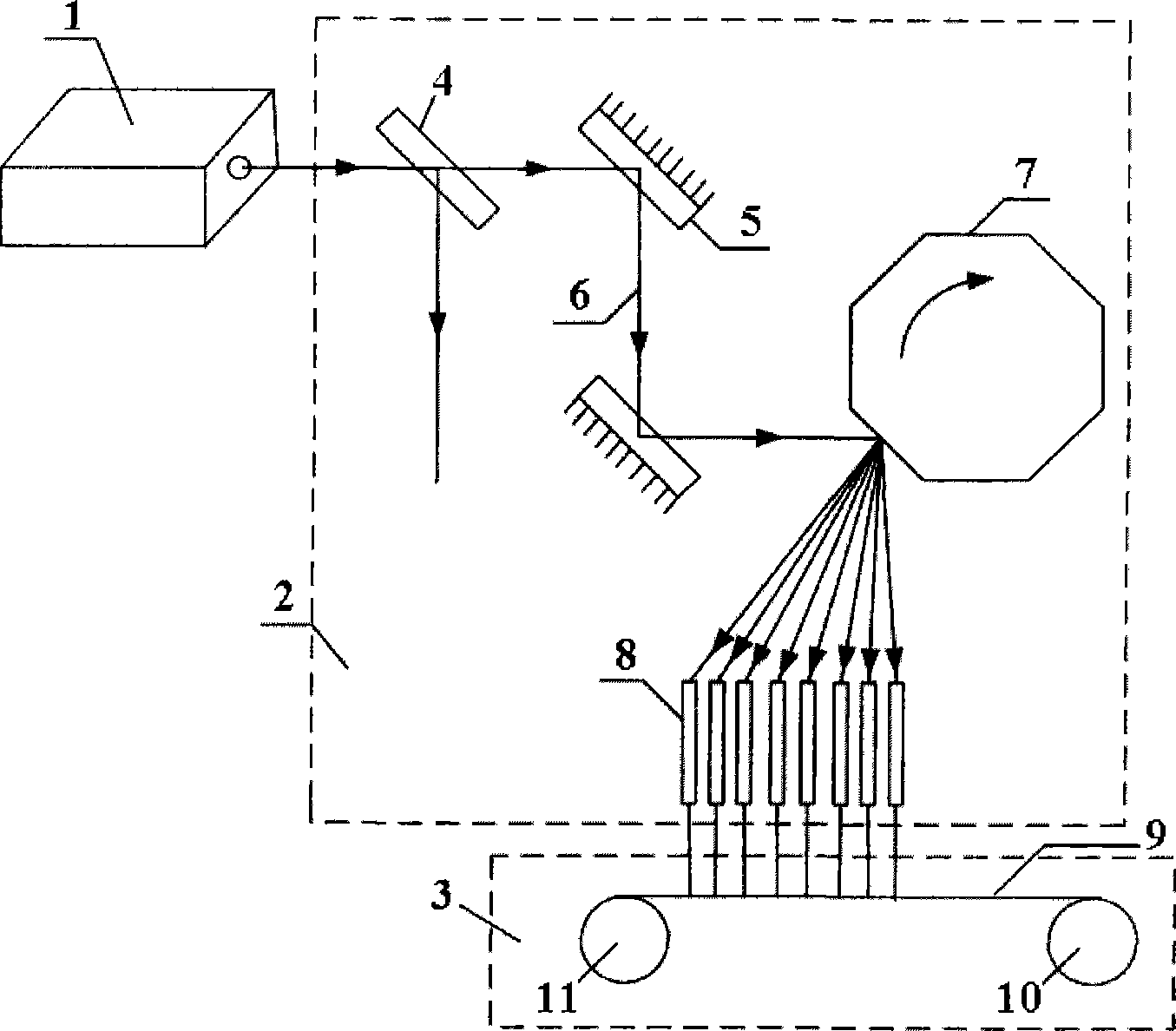

[0044] 1. Rotating polygonal prism drilling method

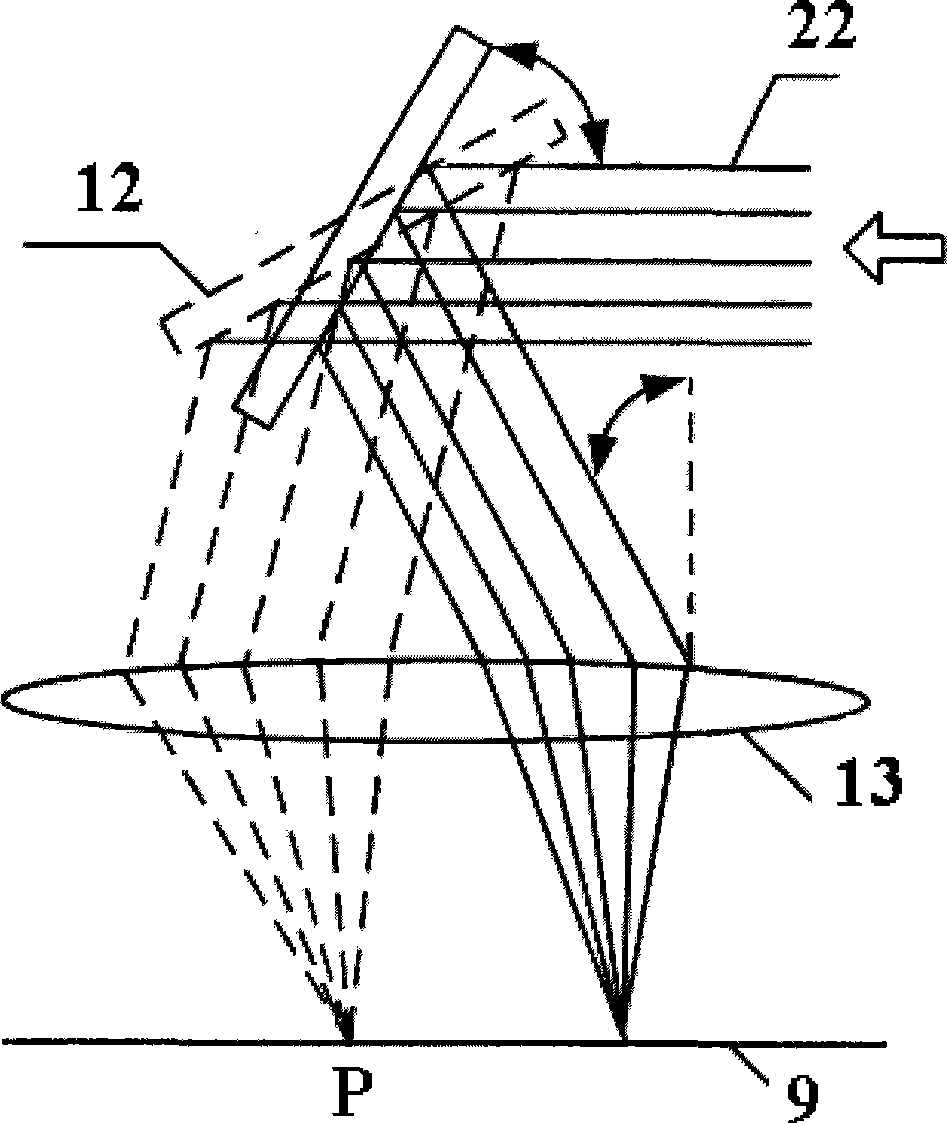

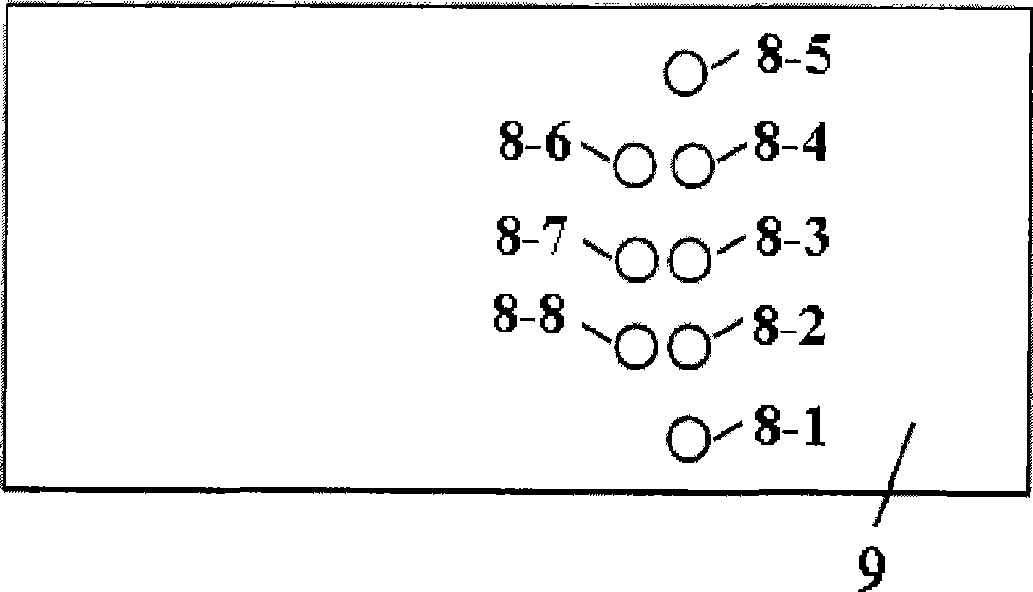

[0045] See figure 1 The method is: the continuous laser beam output by the continuous laser 1 is split by a set of optical half mirror 4 and the total mirror 5, and then scanned and split by a rotating polygonal prism 7 (hereinafter referred to as the polygonal prism 7) to form a multi-channel timing sequence There are successively pulsed laser beams, which are respectively focused by multiple focusing heads 8 to form multiple focused light spots that emit light successively on the surface of the continuously moving tipping paper 9. These focused light spots make the tippin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com