Thin material laser on-line perforating device

A thin material, punching device technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problem of not being widely popularized, easy to block the exhaust system by waste, high investment and cost, etc. , to achieve the effect of high laser energy utilization efficiency, low cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

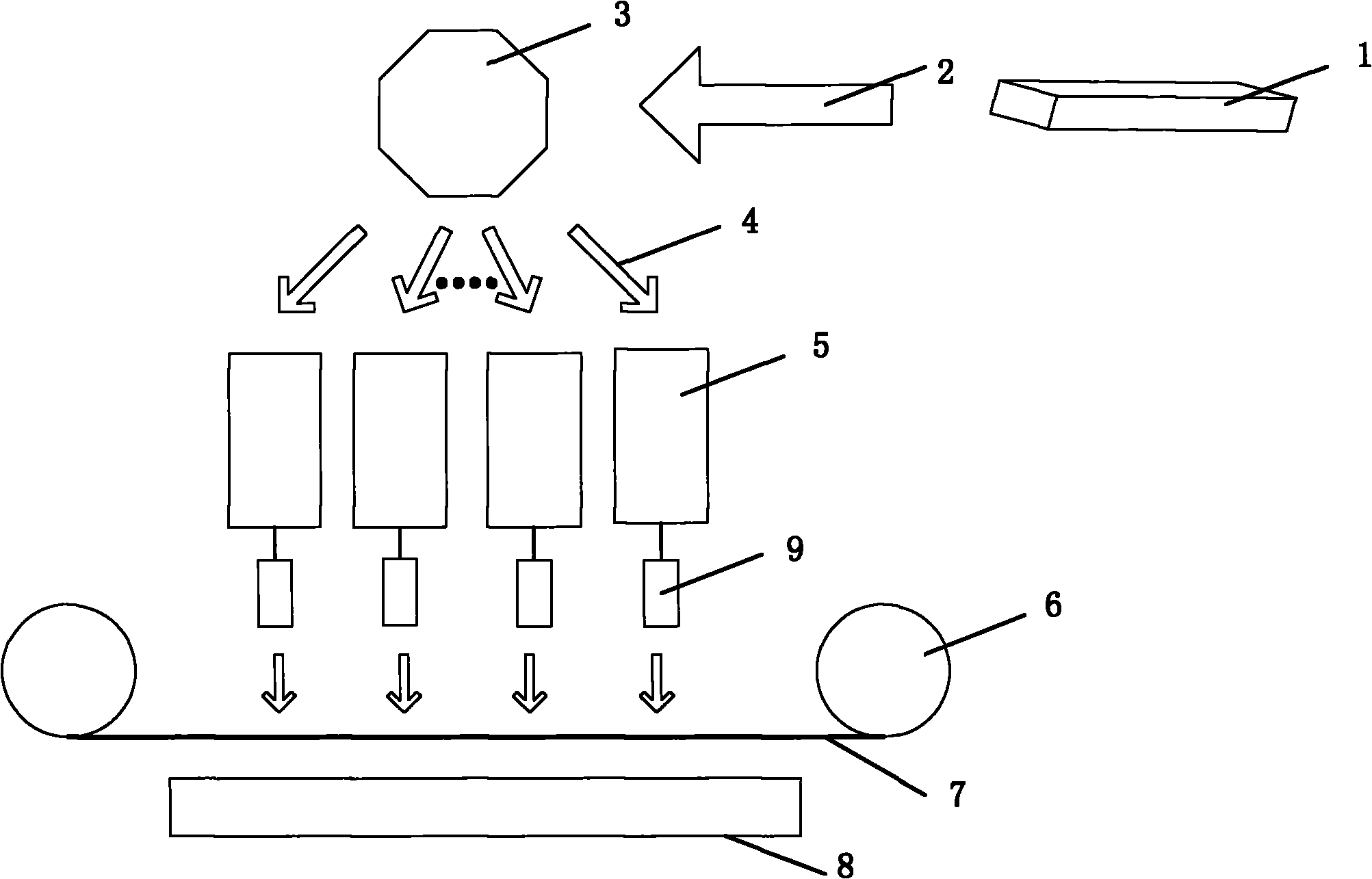

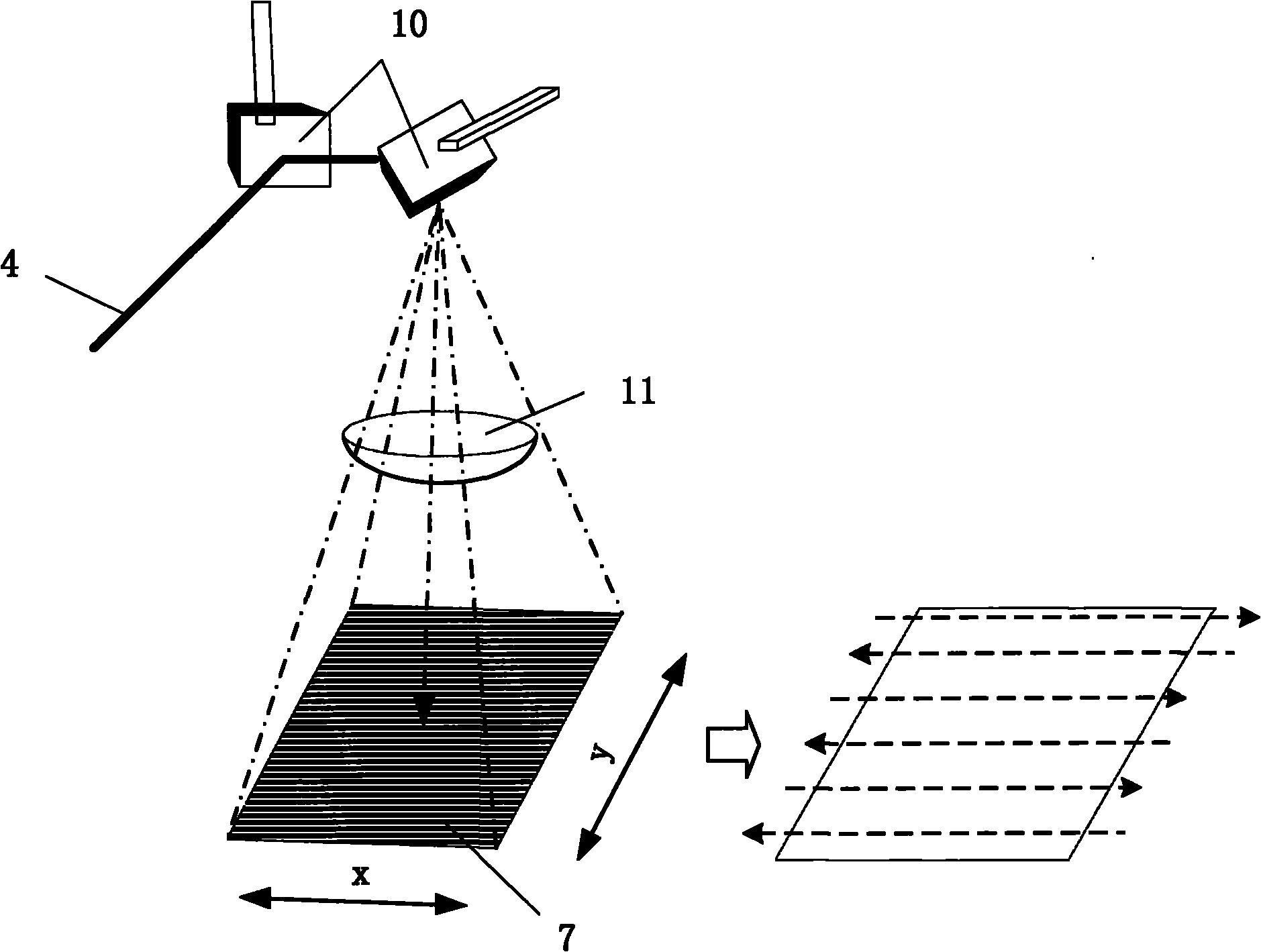

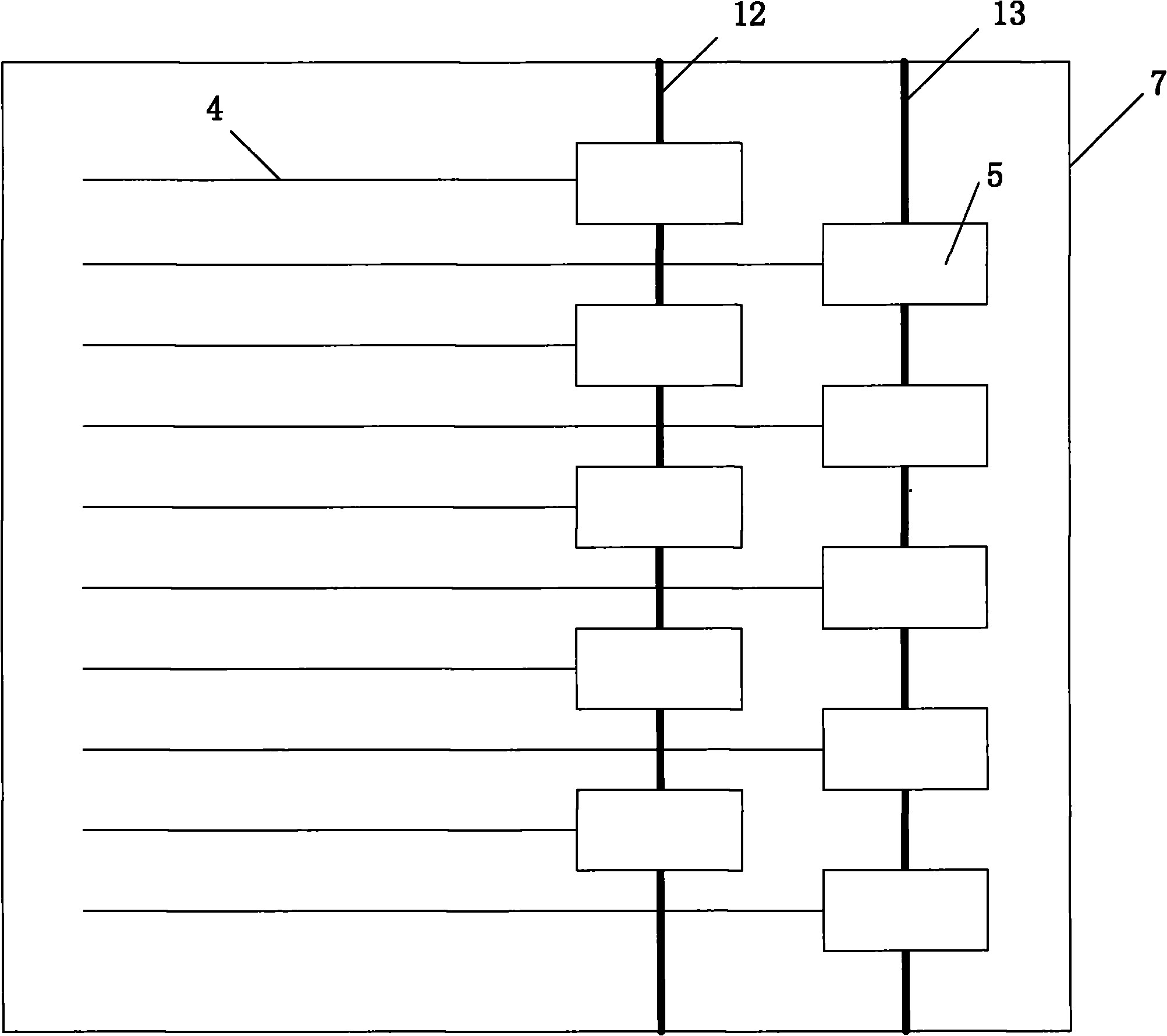

[0026] Embodiment: first as figure 1 As shown, the thin material laser online drilling device provided by the present invention includes a high-power continuous laser 1, a polygonal mirror beam splitting mechanism, a vibrating mirror scanning focusing system, a punching output mechanism and a feeding mechanism; wherein the polygon mirror beam splitting mechanism It includes a polygonal mirror 3 and a high-speed motor (omitted in the figure) that drives the polygonal mirror 3 to rotate, and the number of faces of the polygonal mirror is eight (of course, the number of faces can also be other). The galvanometer scanning focusing system is composed of ten galvanometer scanning focusing mechanisms 5 (not all shown in the figure), and the punching output mechanism is composed of one-to-one correspondence with the galvanometer scanning focusing mechanisms 5 and is arranged on the walking path. Ten laser drilling processing heads 9 (not all drawn in the figure) above the feeding mech...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com