A dynamic measurement system and measurement method for material reflectance changing with temperature

A technology of temperature measurement and dynamic measurement, applied in the field of optics, can solve the problems of difficulty, processing or processing, or not, and achieve the effect of reducing processing costs and improving utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

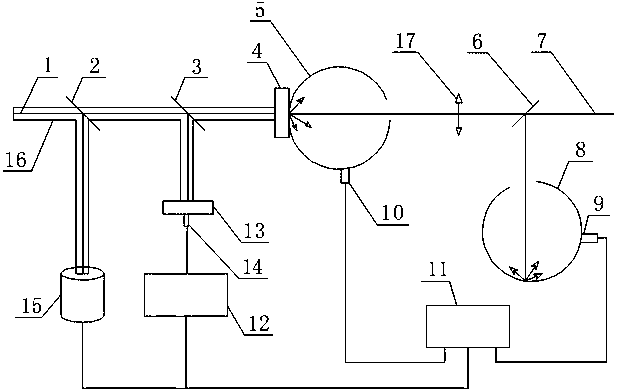

[0020] Such as figure 1 As shown, put two test samples of the same state according to figure 1 The placement shown in , requires that the two test samples have the same linear distance from the 45° 5 / 5 beam splitter 3, and the surface normals of the test samples are perpendicular to each other, so as to achieve the same beam size at the surface position of the two test samples , Laser parameters of the same power density.

[0021] Thermocouples are placed on the non-heated laser beam irradiated surface of the temperature measurement sample for temperature measurement by welding or armoring. The thermocouple installation position is preferably the center point of the non-heated laser beam irradiated surface of the temperature measurement sample, and the metal material is welded. , ceramic or high molecular polymer material for the armor.

[0022]Before the two test samples are heated by the laser beam 1, the probe laser beam 7 is split by the spectroscope, one beam is guided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com