Thin material laser online perforating device

A thin material and punching device technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of not being widely promoted, waste easily clogging the exhaust system, investment and cost are not small, etc. , to achieve the effect of high laser energy utilization efficiency, easy technology implementation, and good cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

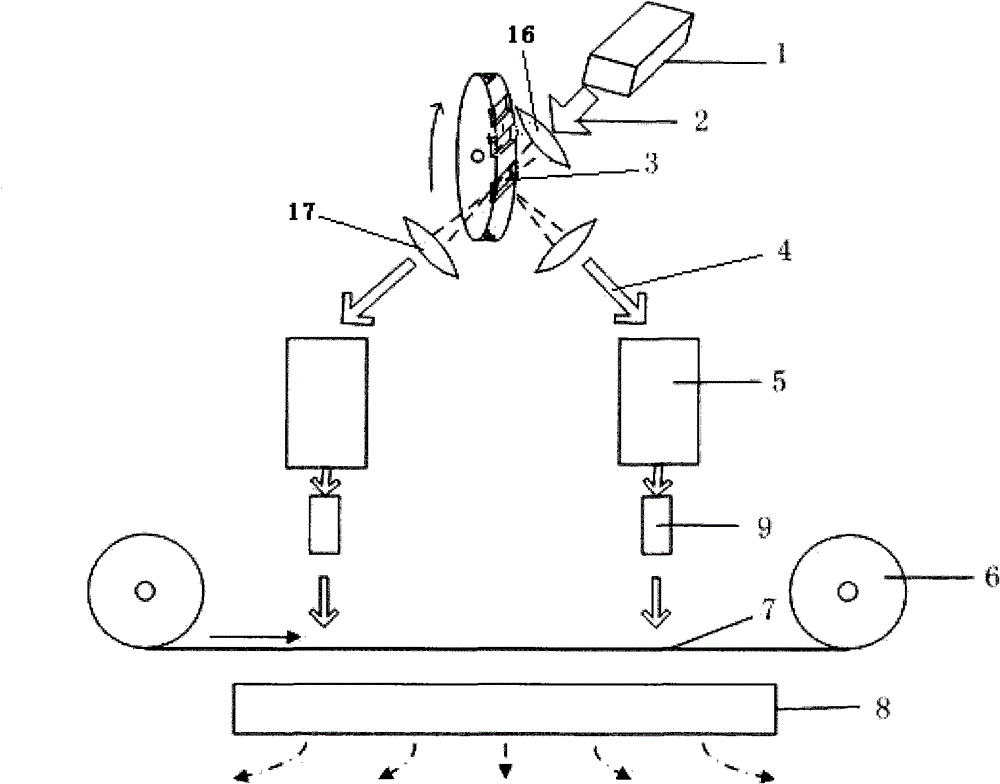

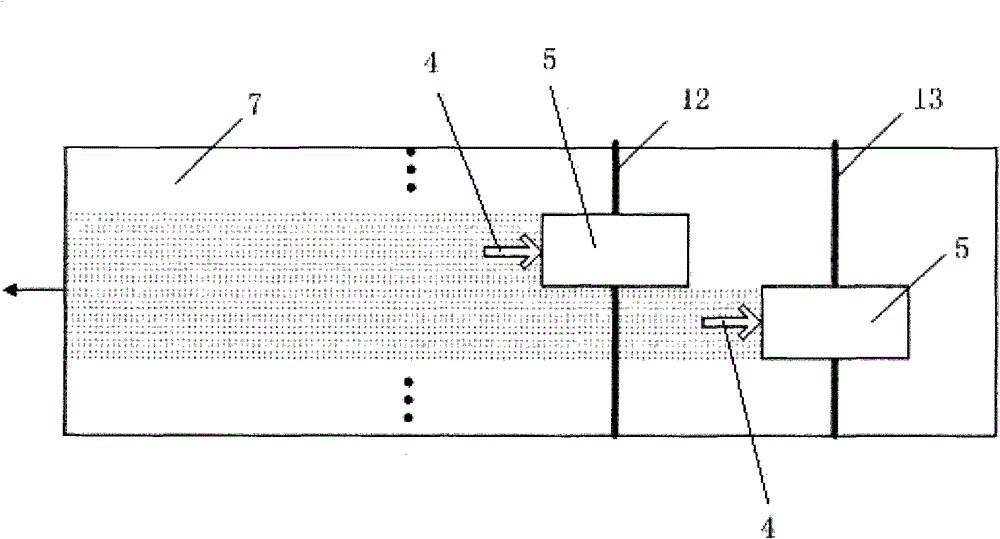

[0034] Example: First combine figure 1 , figure 2 As shown, the thin material laser on-line drilling device provided by the present invention consists of a high-power continuous laser 1, an optical splitter mechanism, two galvanometer scanning and focusing mechanisms 5, a feeding mechanism, which is arranged above the feeding mechanism and interacts with The two galvanometer scanning and focusing mechanisms 5 correspond to the laser drilling head 9 and the dust removal fan 8 together. The high-power continuous laser 1 in this embodiment uses the most mature and cost-effective glass tube CO 2 Laser, which is very important to ensure stable and efficient production. The glass tube CO 2 The wavelength of the laser is 10.6 μm, and the power range is 50 to 500 watts.

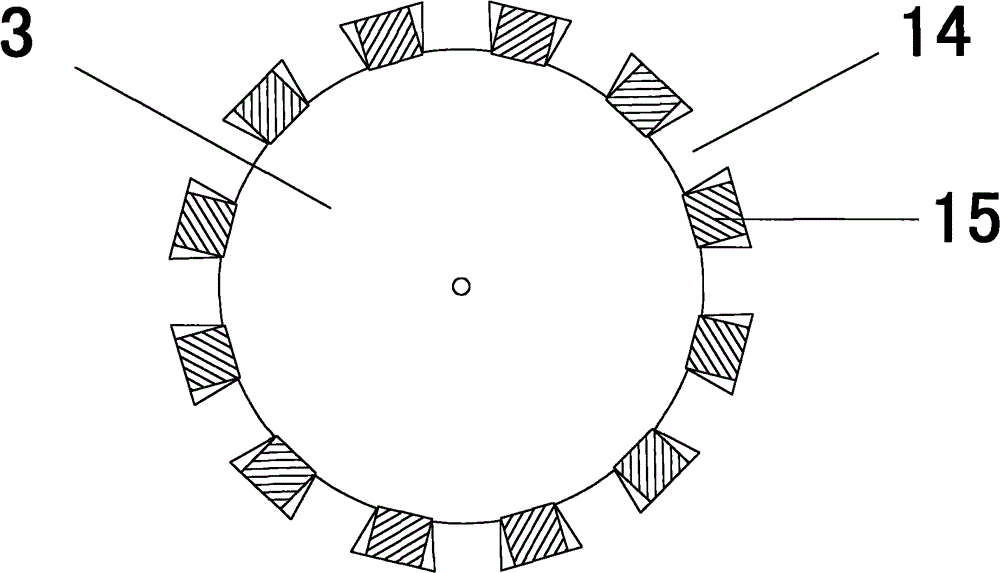

[0035] The optical splitting mechanism in this embodiment is specifically composed of a mechanically modulated sub-disc 3, a high-speed motor (not shown in the figure) for driving the mechanically modulated sub-disc 3 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com