Water-gas dual-purpose filling valve

A filling valve, dual-purpose technology, applied in packaging, bottle filling, liquid bottling, etc., can solve the problems of expensive filling valve, occupying storage space, and unfavorable production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

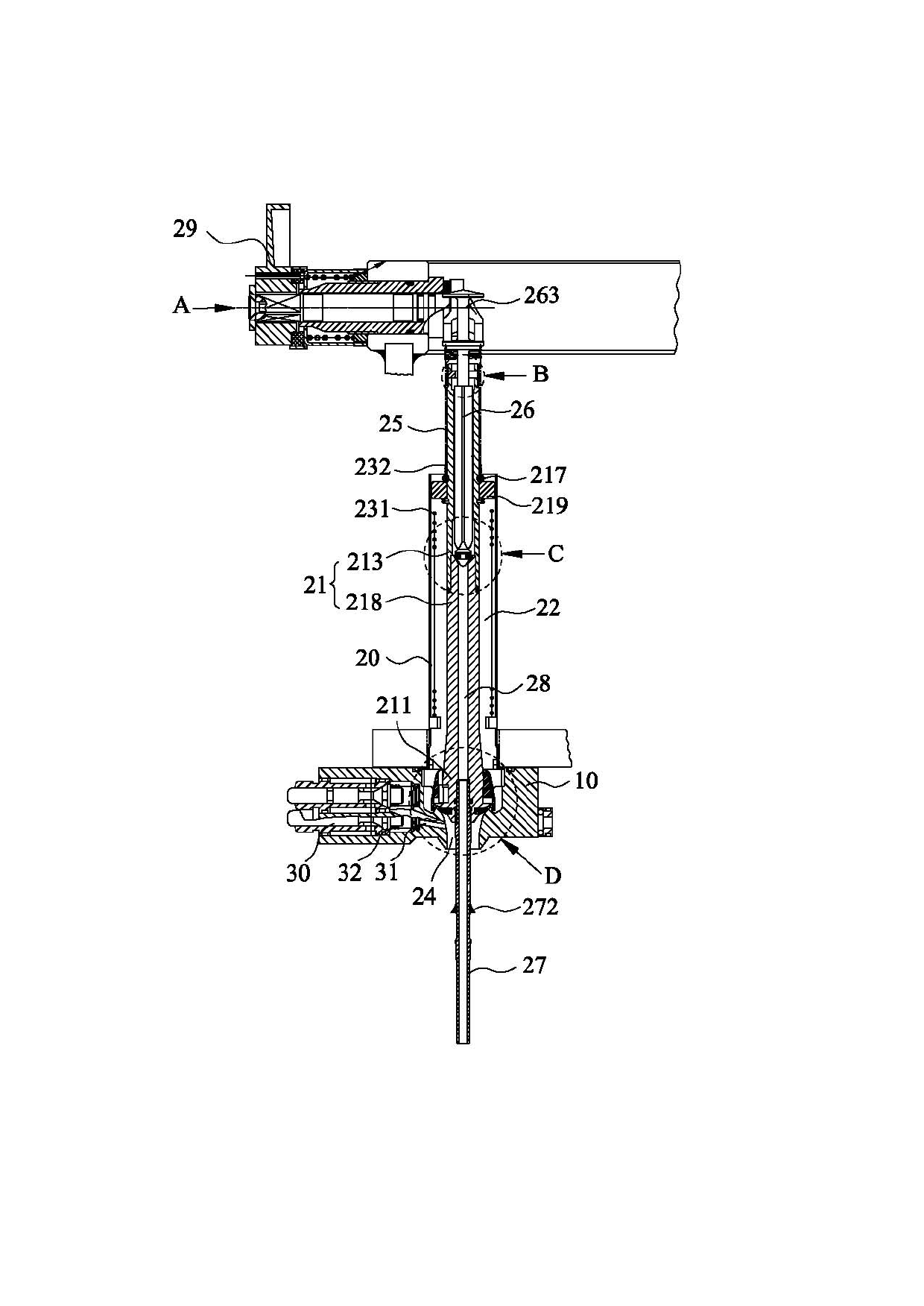

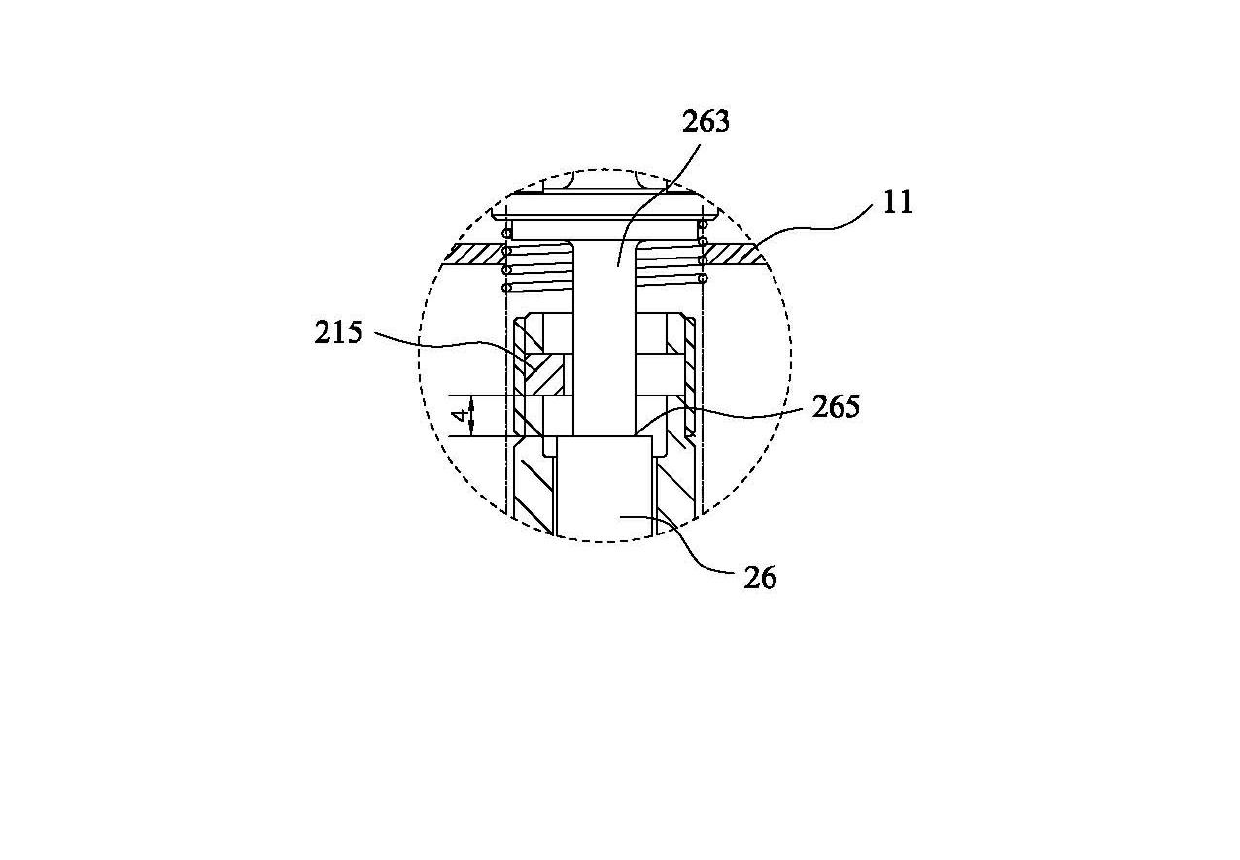

[0050] First, please refer to Figure 1 to Figure 5 As shown, it shows the specific structure of the preferred embodiment of the present invention, including the valve seat 10 and the valve body 20 fixed on the valve seat 10 .

[0051]The valve seat 10 is provided with a filling cylinder 11, the valve body 20 is a cylindrical hollow tube, and a liquid valve spool 21 that can move up and down is vertically arranged in the valve body 20, and the liquid valve spool 21 includes a valve stem 218 And valve stem sleeve 213, valve stem 218 lower end is provided with liquid valve valve head 211, and the valve seat 10 of liquid valve valve head 211 periphery has filling mouth 24, and liquid valve valve head 211 seals tightly in filling mouth 24, The upper end of the valve stem sleeve 213 extends out of the top end of the valve body 20 . A liquid inlet channel 22 is formed between the liquid valve spool 21 and the inner wall of the valve body 20, and the liquid inlet channel 22 communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com