Roller surface coarsening processing method using multiheaded high power laser and its device

A processing method and technology of a processing device, which are applied in the field of high-power laser roller surface multi-head texturing processing methods and devices, can solve the problem of increasing the complexity of mechanical systems, cooling systems and optical path systems, working reliability and durability of processing devices. Influence, it is difficult to meet the production needs of large steel plants, etc., to achieve the effect of simple structure, low cost and small thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

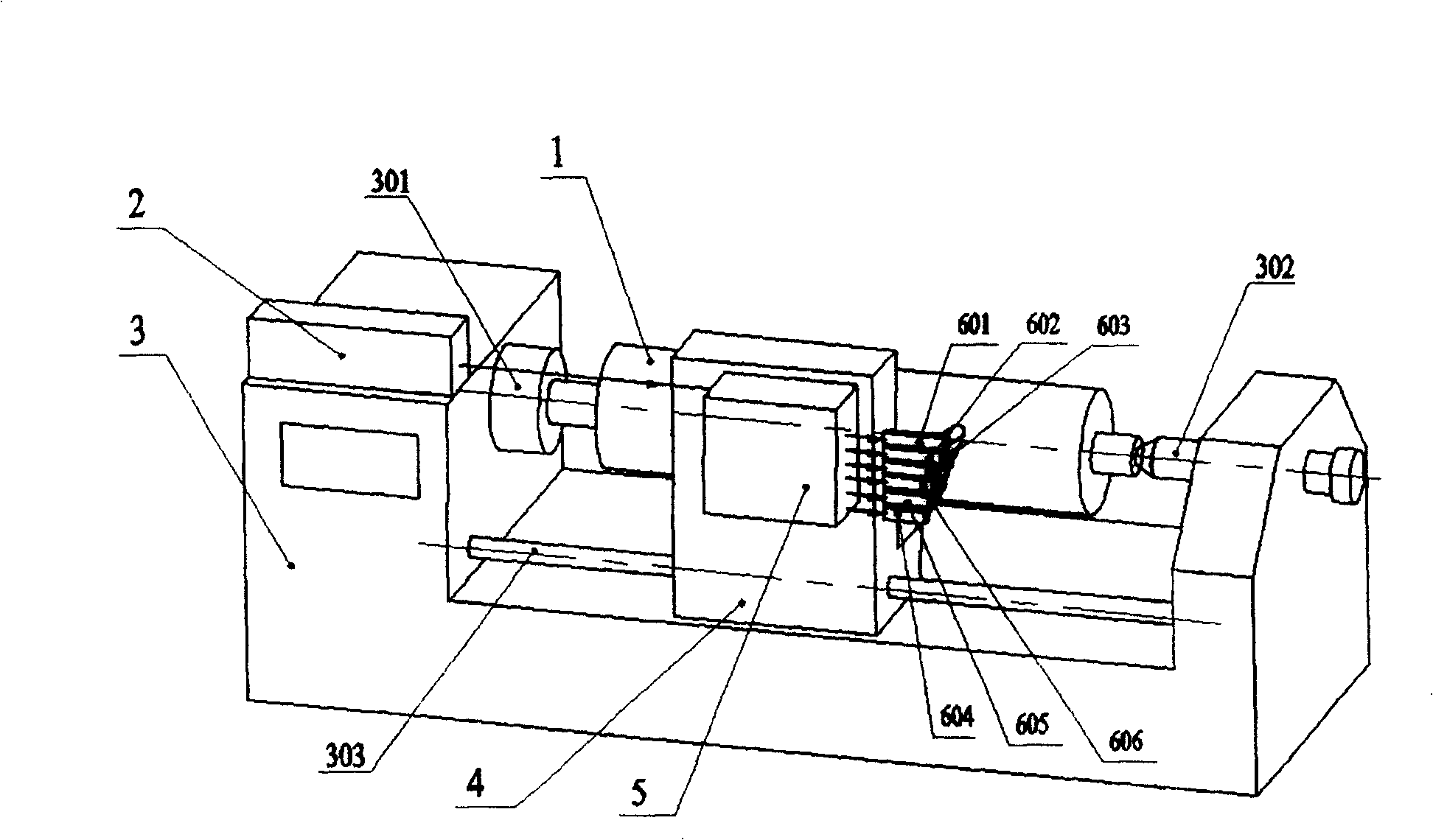

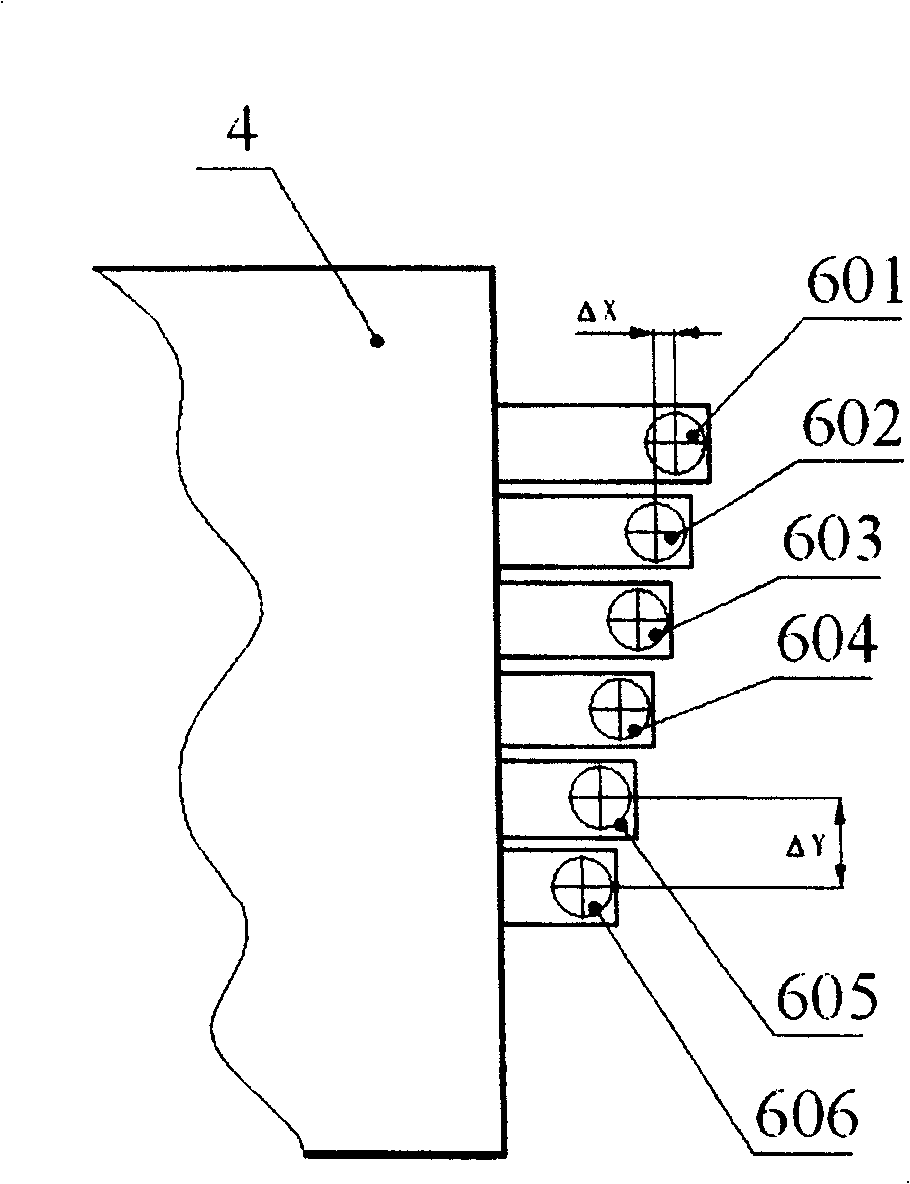

[0023] The high-power laser roller surface multi-head roughening processing method provided by the present invention uses a high-power continuous laser to output a continuous laser beam, and the laser beam is divided into K≥2 pulsed laser beams by a polygonal mirror light splitting mechanism, and then respectively focused by K After the head is focused and output, multi-head texturing is performed on the surface of the roller at the same time, so that the surface of the roller forms K spiral scanning line lattice texturing pit distribution. Specific steps are as follows:

[0024] The roll workpiece 1 is clamped by the roll shaft 301 and the top 302 on the CNC machine tool 3;

[0025] Start the CNC machine tool 3 to make the roll workpiece 1 rotate at a set speed:

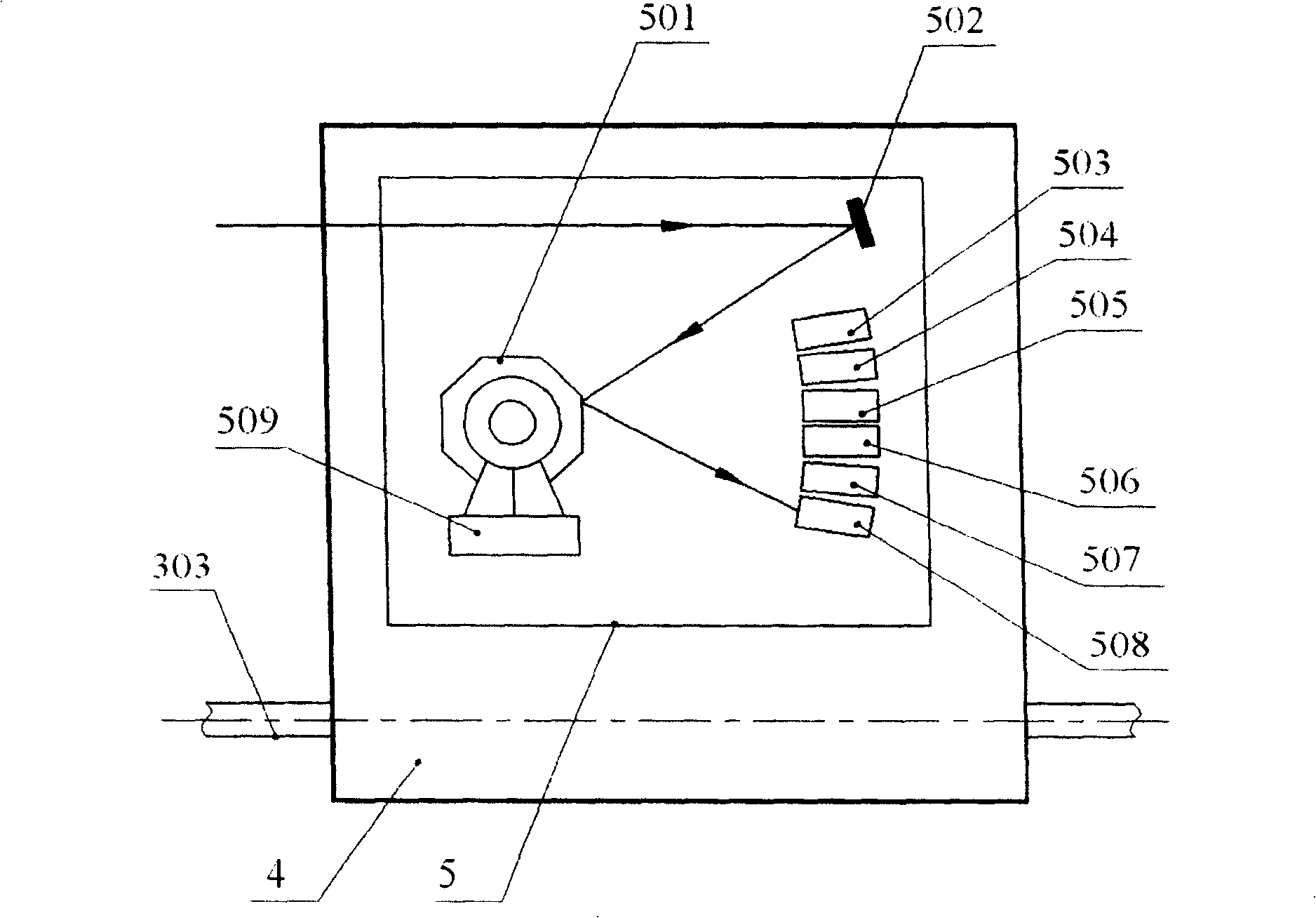

[0026] The continuous laser beam output by the laser 2 enters the polygonal mirror light splitting mechanism 5 installed on the working platform 4, and after being reflected by the total reflection mirror 502, it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com