Double-head integrated laser drilling device for cigarette tipping paper

A technology of cigarette tipping paper and laser drilling, which is applied to laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of large volume, complex equipment structure, and complex structure of the whole machine, and achieve small volume and convenient adjustment , the effect of structural simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

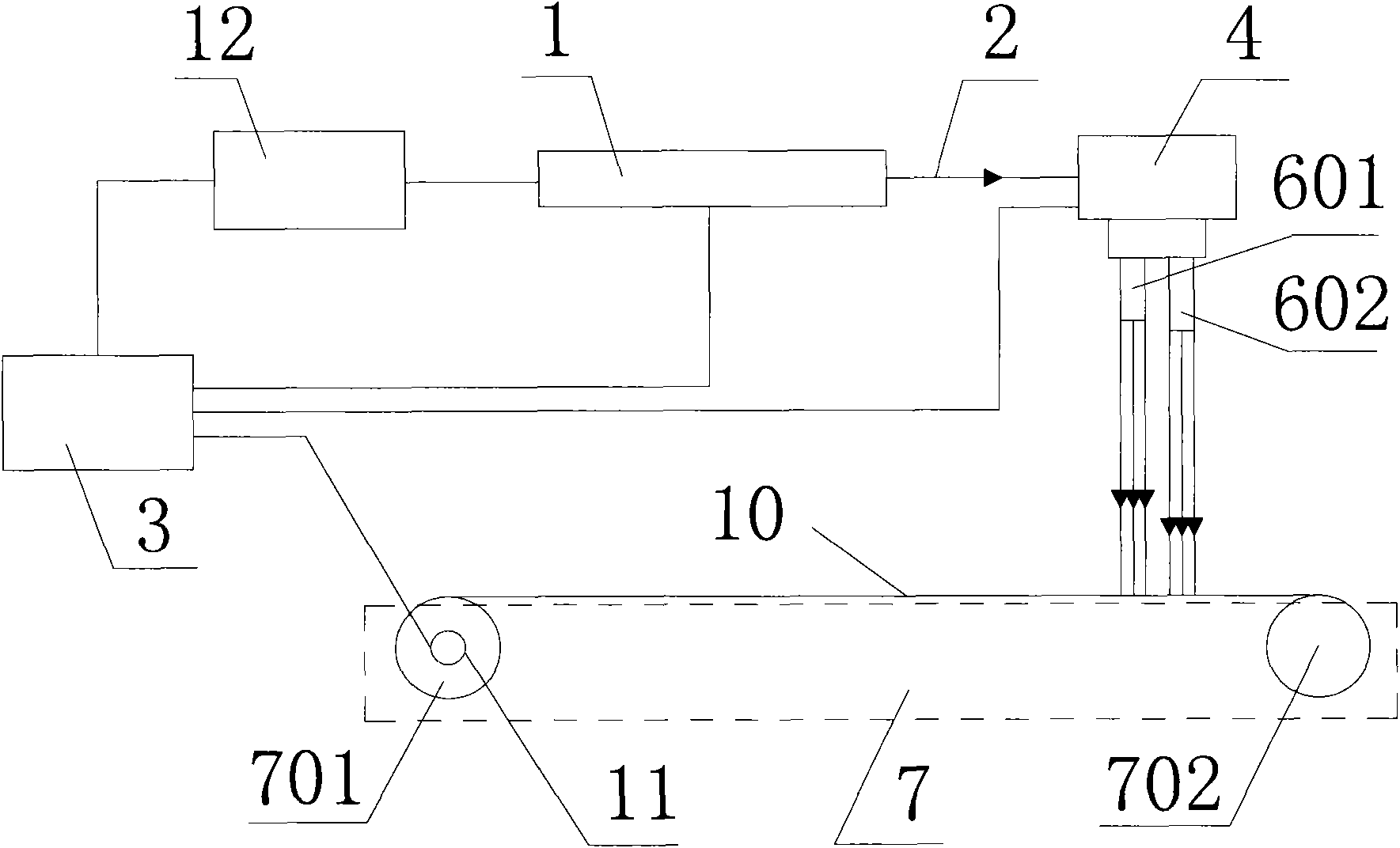

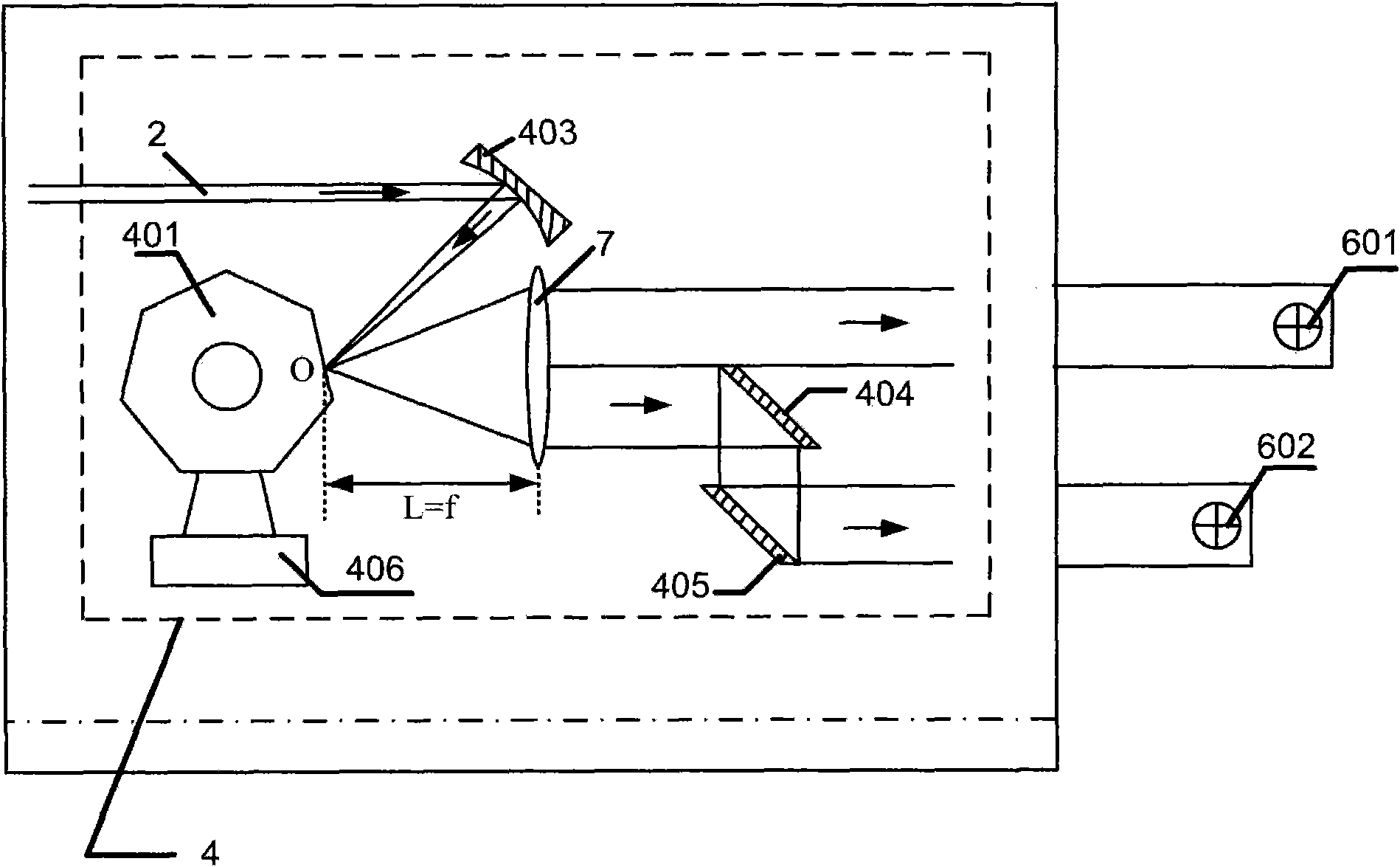

[0038] Example 1: First combine figure 1 , figure 2 As shown, the double-head integrated laser drilling device for cigarette tipping paper provided in this embodiment includes a laser 1, a control system 3, a polygonal mirror beam splitting mechanism 4, a focusing mechanism, and a paper-feeding mechanism that drives the tipping paper 10 to move continuously. 7. The tipping paper online speed detection device 11 and the laser cooling system 12 are jointly composed. Where: the laser 1 is a high-power continuous CO 2 Laser, its output power is continuously variable from 50 to 4000 watts, and the laser output wavelength is 10.6 μm. The polygonal mirror beam splitting mechanism 4 among the present embodiment is made up of polygonal mirror 401, the high-speed motor 406 that drives polygonal mirror 401 to rotate, total reflection mirror group, the first reflection that is used for the continuous laser beam 2 that laser 1 sends is focused on a certain working surface of polygonal m...

Embodiment 2

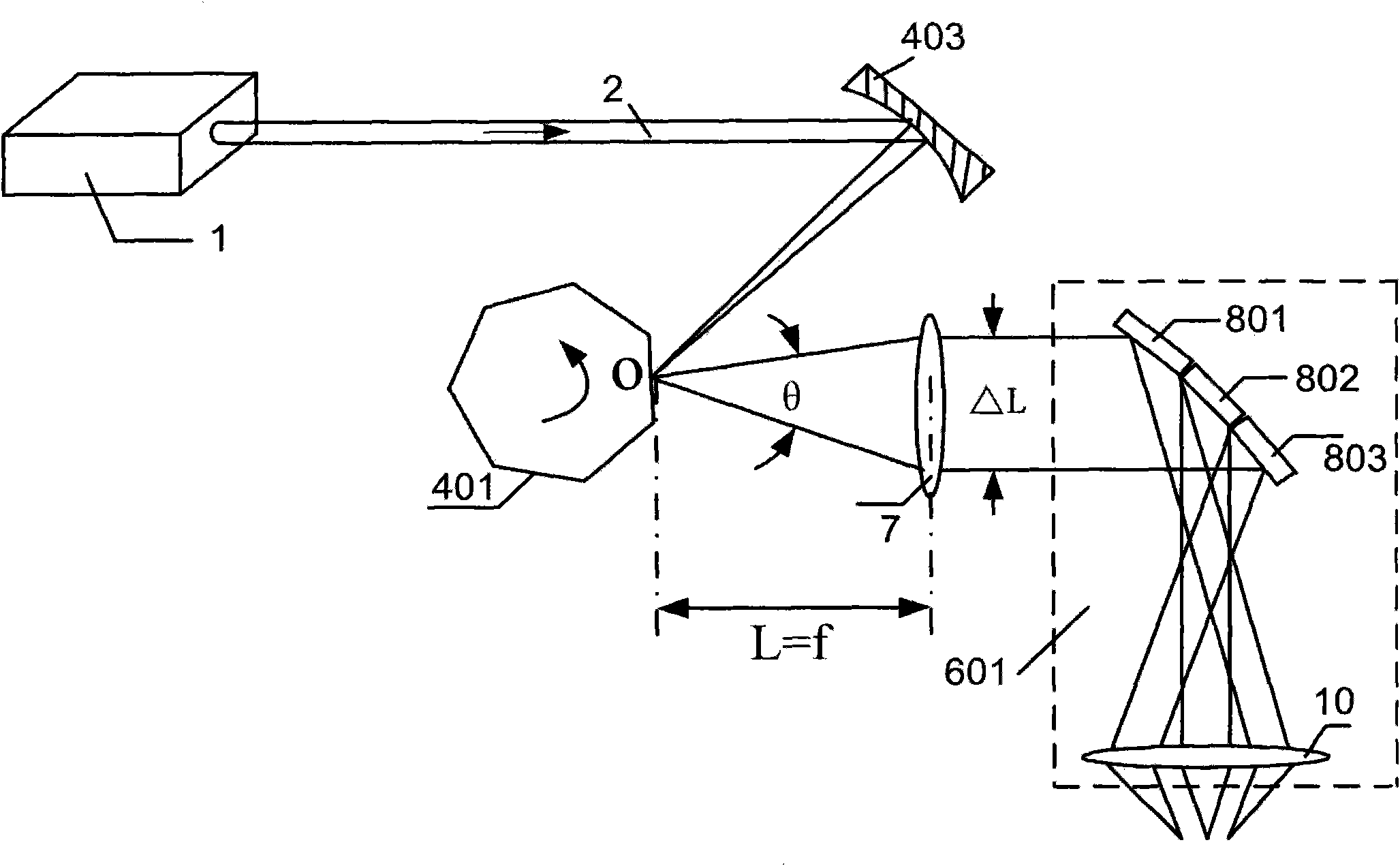

[0046] Embodiment 2: as Figure 4 As shown, the double-head integrated laser drilling device for cigarette tipping paper provided by this embodiment has the same external structure as that of Embodiment 1, but the difference is that it uses the first reflection type in the polygonal mirror beam splitting mechanism 4 involved in Embodiment 1 The focusing lens 403 is replaced by the first transmissive focusing lens 402, and the internal structures of the two integrated punching heads 601 and 602 are redesigned at the same time, specifically taking the first integrated punching head 601 as an example, this embodiment N=3 closely arranged focusing lenses 901, 902, 903 ( Figure 4 The high-speed motor 406 connected to one side of the polygon mirror 401 is omitted). The working principle of this embodiment can be found in figure 1 , figure 2 and Figure 4 The description shown is as follows: the continuous laser beam 2 output by the laser 1 enters the polygonal mirror beam spli...

Embodiment 3

[0047] Embodiment 3: as Figure 5As shown, the double-head integrated laser drilling device for cigarette tipping paper provided by this embodiment has the same external structure as that of Embodiment 1, but the difference is that it uses the first reflection type in the polygonal mirror beam splitting mechanism 4 involved in Embodiment 1 The focusing mirror 403 is replaced by the first transmissive focusing mirror 402, and the second transmissive focusing mirror 7 is replaced by the second parabolic reflective focusing mirror 5; All have been redesigned, specifically taking the first integrated punching head 601 as an example, in this embodiment, N=3 closely arranged focusing lenses 901, 902, 903 ( Figure 4 The high-speed motor 406 connected to one side of the polygon mirror 401 is omitted). The working principle of this embodiment can be found in figure 1 , figure 2 and Figure 5 The description shown is as follows: the continuous laser beam 2 output by the laser 1 en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com