Copper plating device and copper plating process using external tank to dissolve electrolytic copper

A technology of electrolytic copper and copper dissolution, applied in the direction of electrolytic components, electrolytic process, electrodes, etc., can solve the problems of impure plating solution, lower utilization rate, high production cost, etc., achieve simple production and maintenance, improve utilization rate, and reduce energy consumption Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

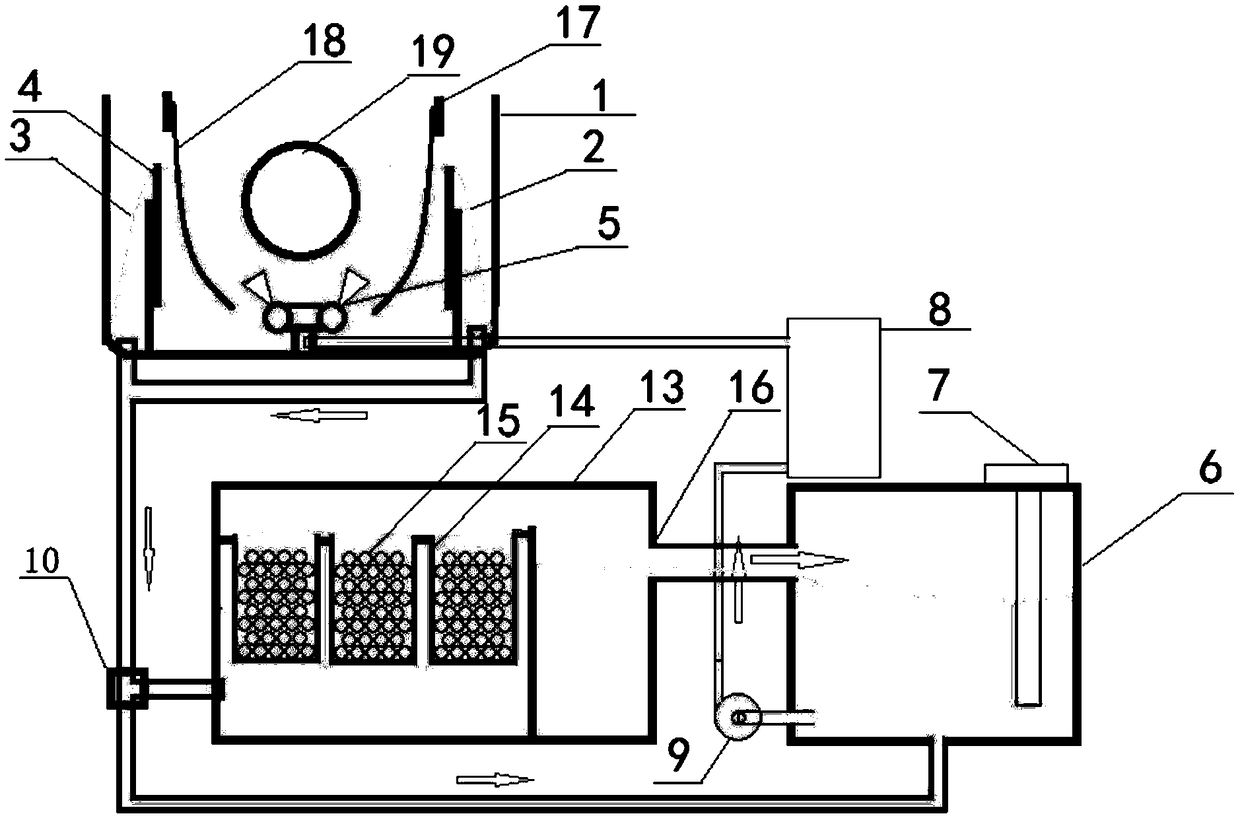

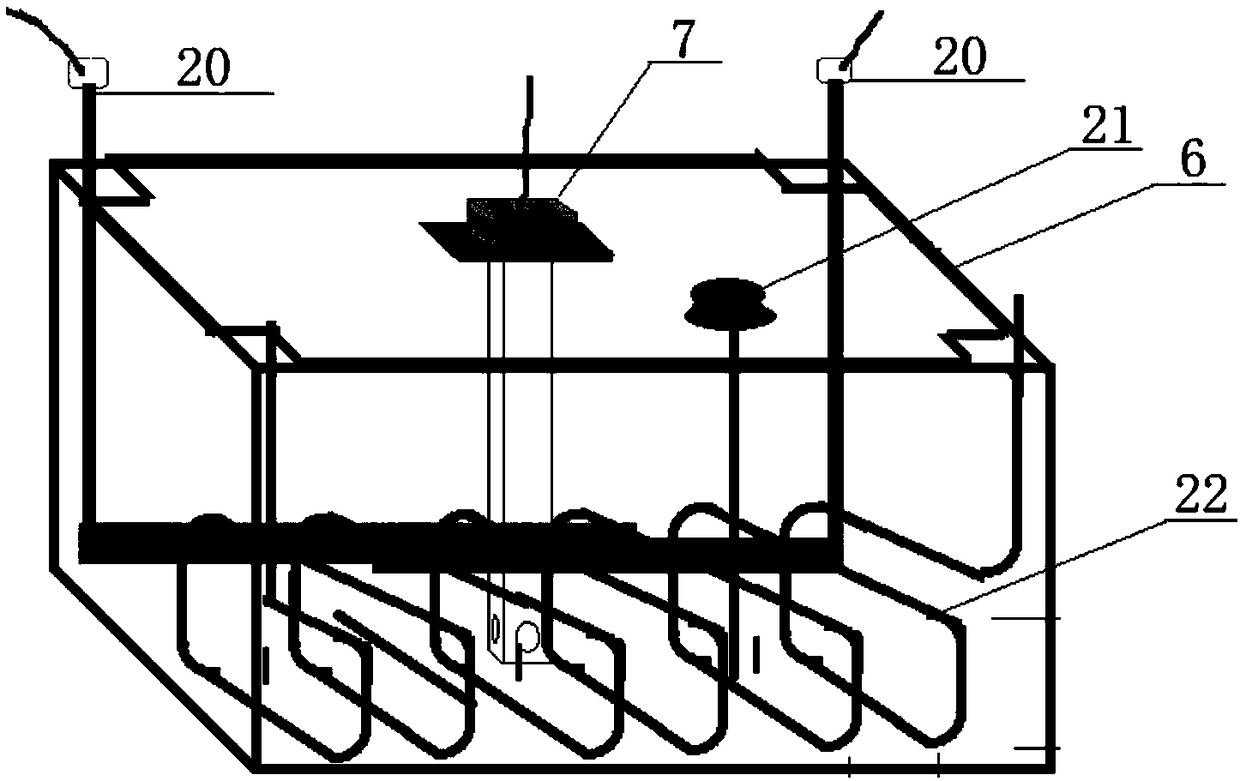

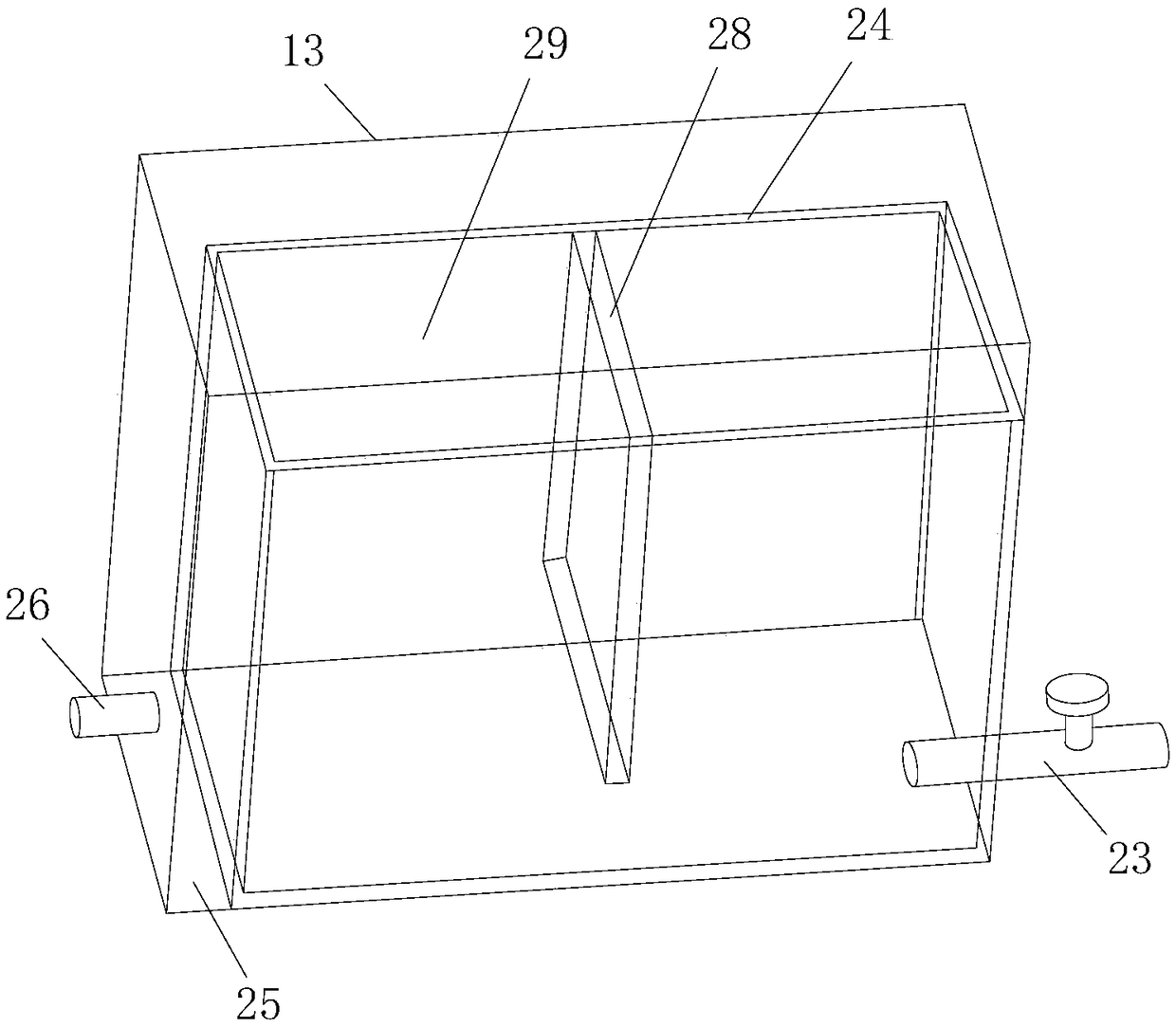

[0037] In this example, refer tofigure 1 , figure 2 , image 3 and Figure 4 , the copper plating device using an external tank to dissolve electrolytic copper includes a plating tank 1, which is provided with a plating solution nozzle 5, a copper row 17 and an insoluble anode, and the plating tank 1 is connected to a liquid storage tank 6 to form a plating solution Circulation structure; also includes a copper-dissolving tank 13, which is provided with a number of titanium baskets 14 for placing electrolytic copper 15 (copper corners or copper balls), and the liquid inlet end of the copper-dissolving tank 13 is connected to the plating tank 1 It is connected with the return pipe of the liquid storage tank 6, and the liquid outlet of the copper-dissolving tank 13 is directly connected with the liquid storage tank 6 to form a copper ion replenishment mechanism for the liquid storage tank 6; the liquid storage tank 6 is provided with a copper ion concentration monitor 7.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com