Laser generation method, YAG (yttrium aluminum garnet) laser and laser texturing processing device

A technology of YAG laser and production method, which is applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problem that it is difficult to meet the production needs of large steel rolling mills, it is not suitable for cold rolling roughness transfer, and the pulse width of acousto-optic Q-switching Narrow problems, to achieve high texturing efficiency, high peak power, and high peak power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

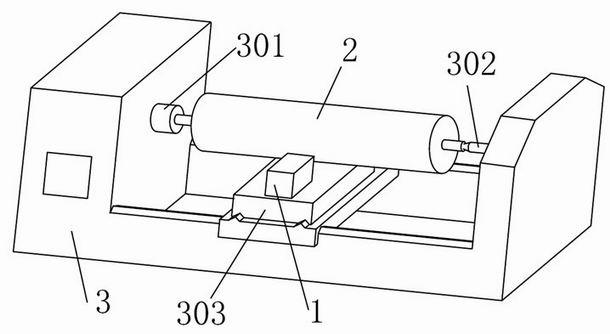

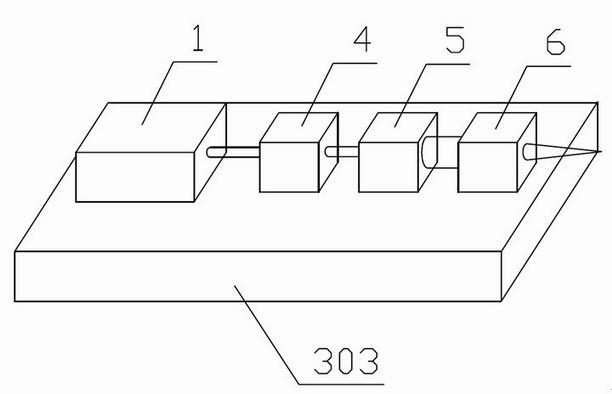

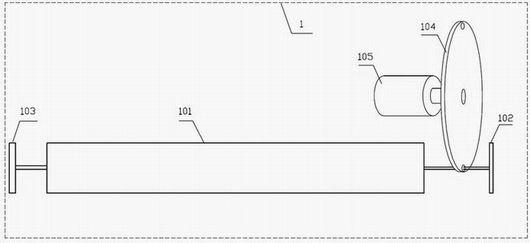

[0044] Embodiment 1: as figure 1 Shown is a specific embodiment of the high-power pulse train group modulation YAG laser texturing processing device of the present invention, which includes a laser system and a numerical control machine tool 3, and a working platform driven by a translation guide rail is mounted on the bed of the numerical control machine tool 3 303 and the roll shaft 301 and the top 302 for installing the roll workpiece 2; the laser system is installed on the work platform 303, wherein the laser system includes a burst group modulation YAG laser 1, a light guide mechanism 4, a beam expander collimation system 5 and Laser textured focusing head 6, the structural diagram of which is installed on the working platform is as follows figure 2 shown. combine image 3 As shown, the composition of the pulse train group Q-modulated laser 1 in this embodiment is as follows: a resonant cavity composed of an output mirror 102 and a total reflection mirror 103, a contin...

Embodiment 2

[0049] Embodiment 2: Take two lasers working in parallel as an example to illustrate it, such as Figure 7 As shown, the pulsed laser beams emitted by the burst group modulated YAG lasers 111, 112 respectively pass through the light guide mechanisms 411, 412, the beam expander collimation systems 511, 512, and then are focused by the laser texturizing focusing heads 611, 612 to form Two very small focused light spots are formed on the surface of the roll workpiece, and finally the surface of the roll workpiece 2 is roughened. Under the centralized control of the CNC machine tool 3 on the rotational speed of the roll workpiece 2, the rotational speed of the mechanical modulation disc 1114, 1124, and the position and translation speed of the working platform 303, the focused light spot is processed on the surface of the roll workpiece 2 to form two spiral scanning line dot matrix hairs. Pit distribution, specific combination Figure 6 As shown, the longitudinal point spacing of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com