A Multi-position Transformer Skeleton Transmission Structure

A technology of transformer skeleton and transmission structure, which is used in inductor/transformer/magnet manufacturing, manufacturing tools, metal processing equipment, etc. Simple and compact, high work efficiency, achieve the effect of functional requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

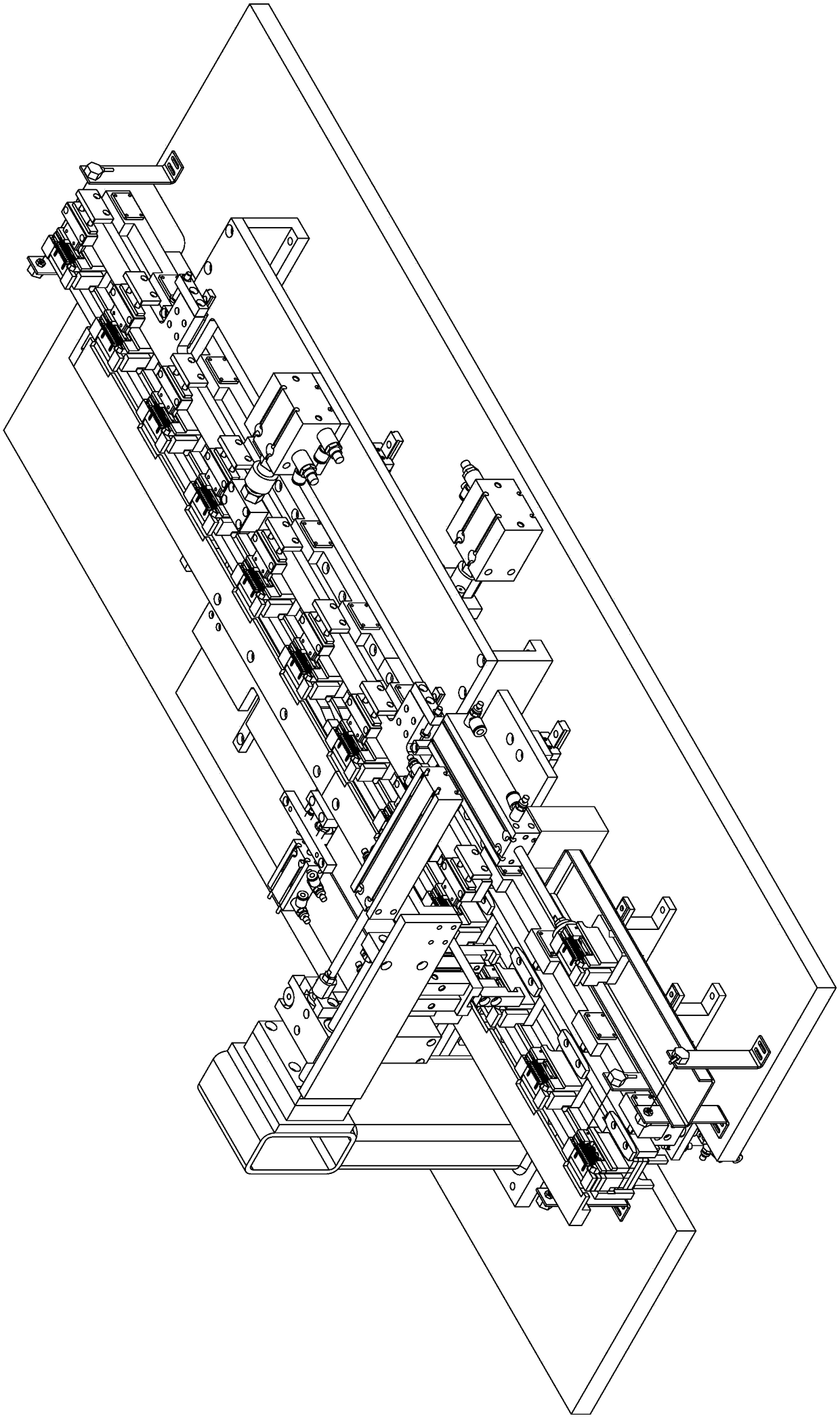

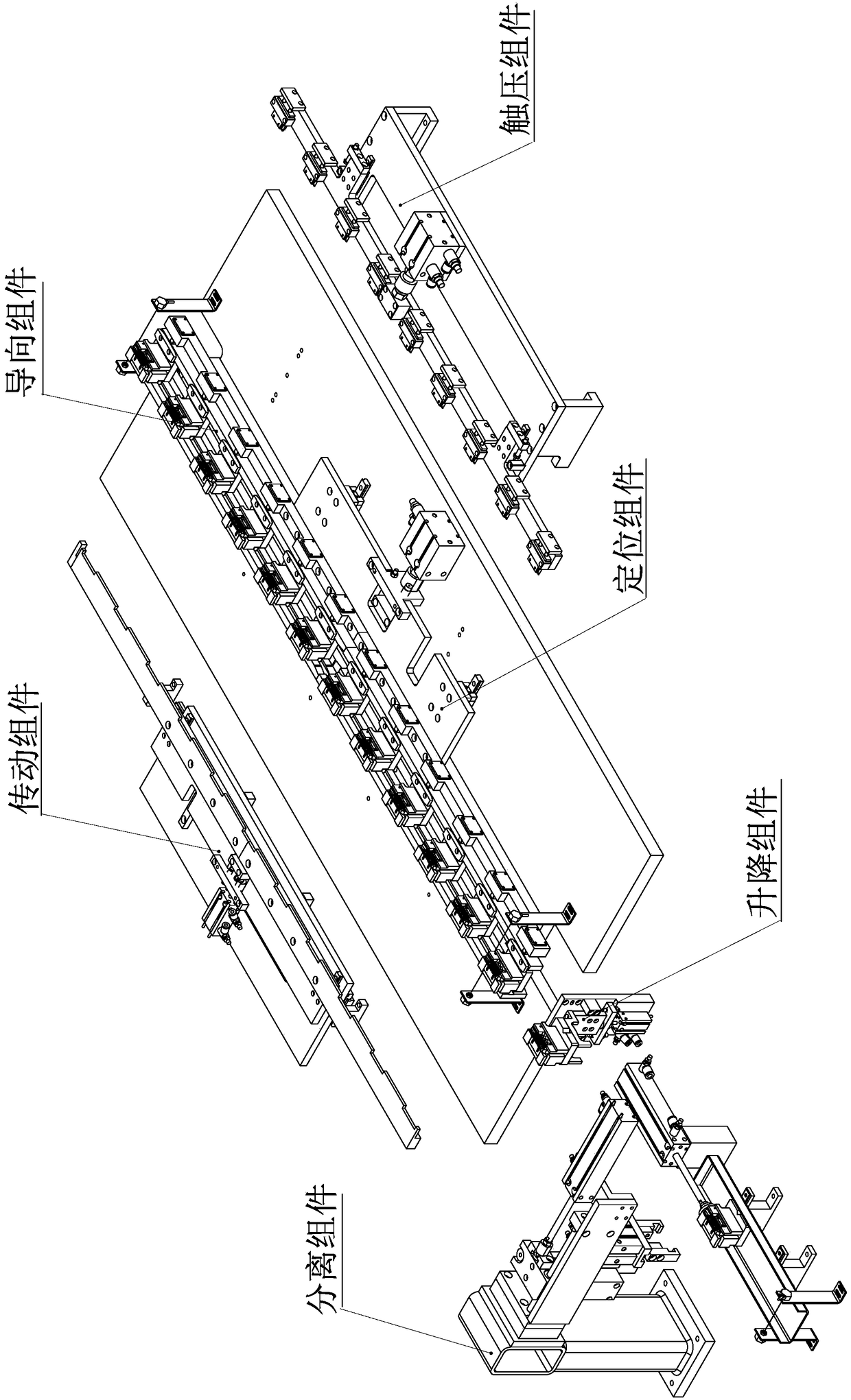

[0040] The present invention will be further described below in conjunction with the drawings and descriptions of the drawings. A multi-station transformer skeleton transmission structure, used to transfer the clamp body and its skeleton to different implementation stations during the soldering process of the transformer skeleton, including the base 1, the clamp body 2 and the skeleton, the sensor 3 and the fixing parts , Guide components, positioning components, touch pressure components, transmission components, lifting components, separation components.

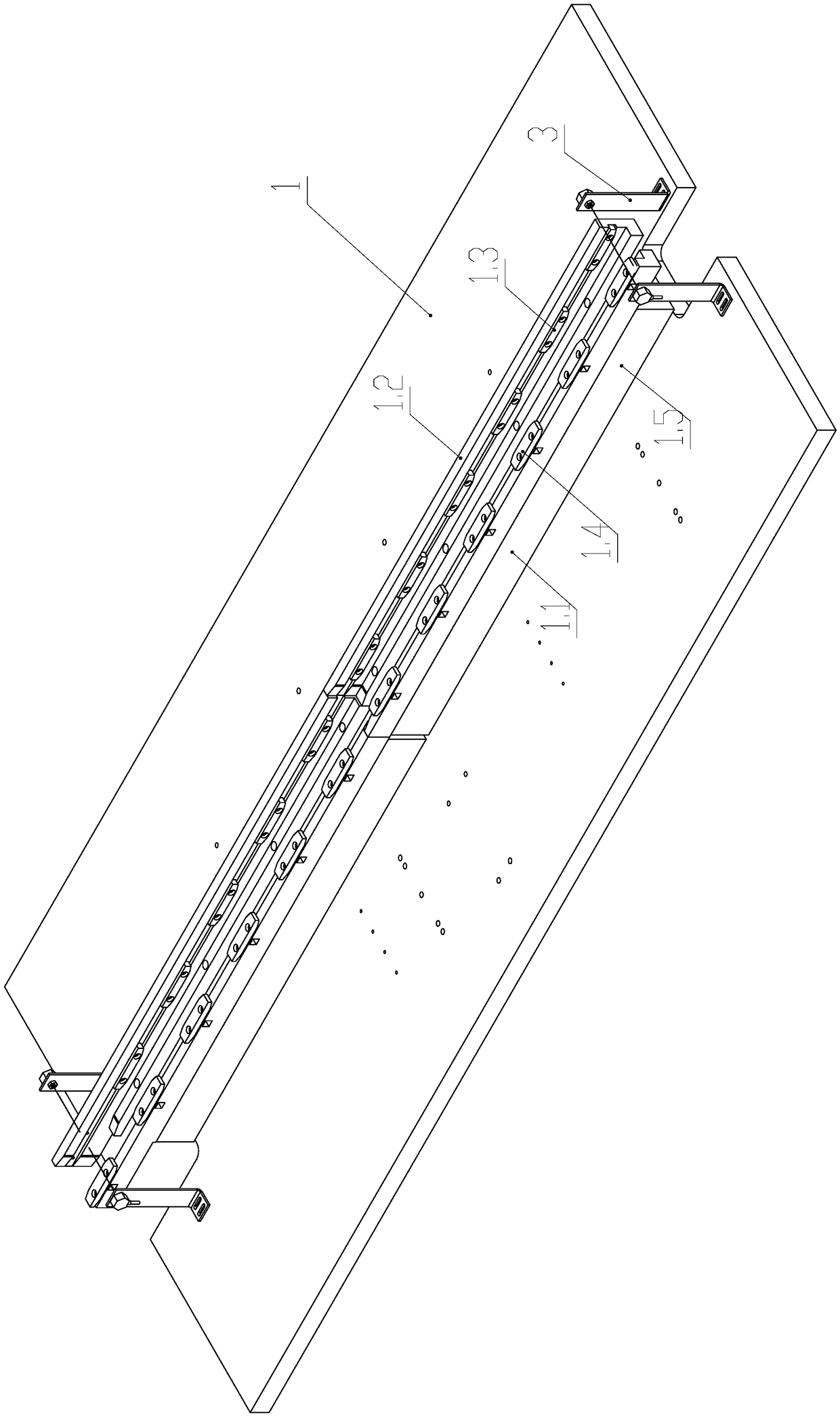

[0041] 1. The guide assembly includes a support block (1.1), a guide bar I (1.2), an insert (1.3), a baffle (1.4), and a guide bar II (1.5).

[0042] The base 1 has a rectangular structure, and is connected with related components through installation holes and positioning holes, and has the function of fixed support. The clamping body 2 and the frame are the carrying objects, which are moved to each station by the transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com