Preparation equipment and process of conveying hopper

A technology of preparation process and equipment, which is applied in the field of preparation equipment and process of hopper, can solve the problems of complex structure and low consistency, reduce the difficulty and time of preparation, avoid complicated process, and improve the effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

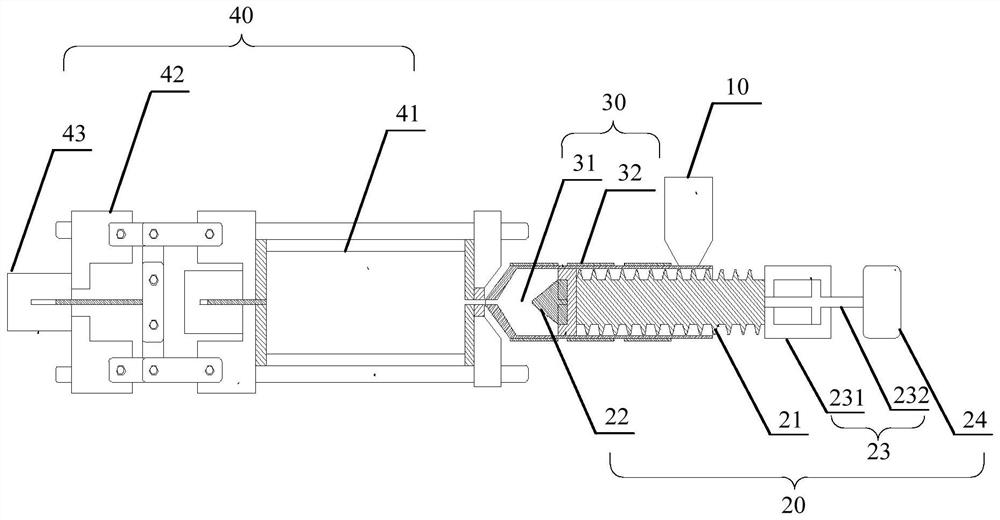

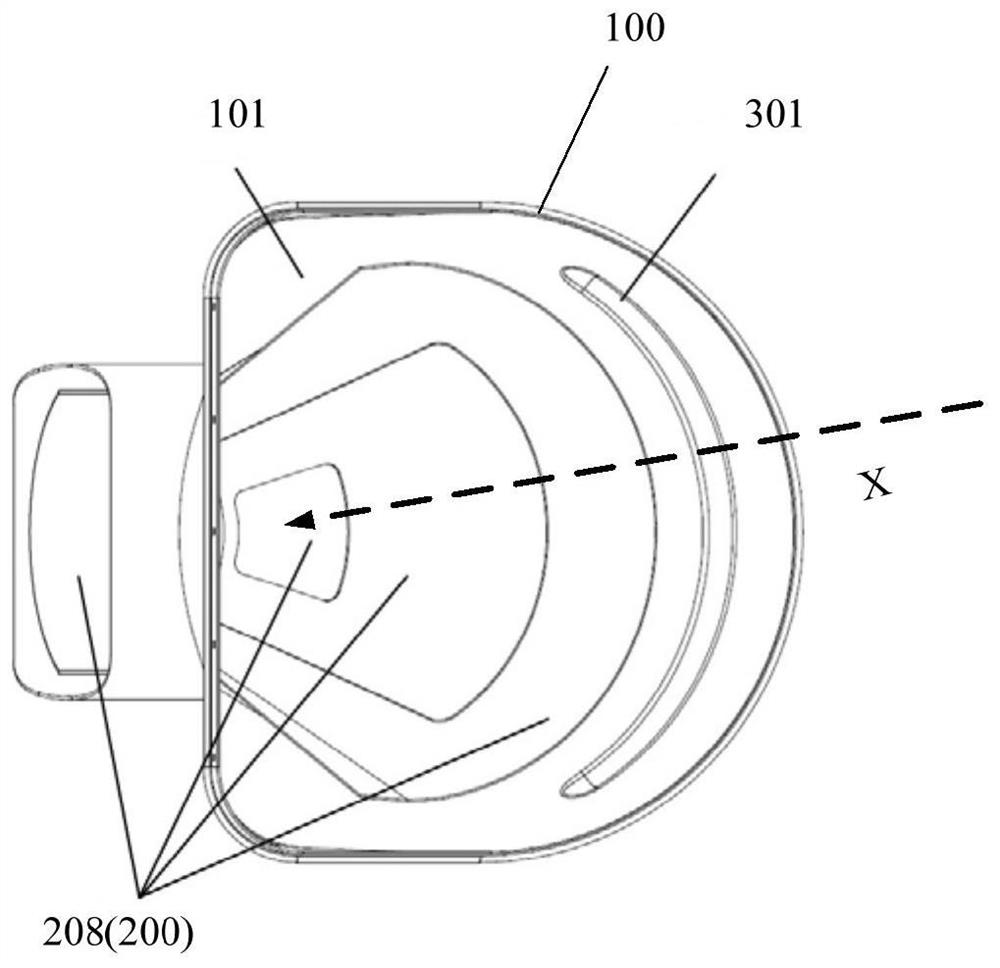

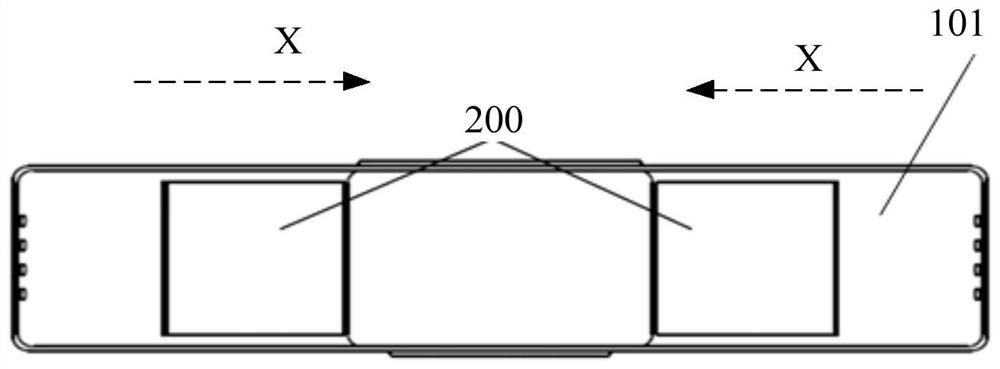

[0047] The preparation equipment of a kind of feeding hopper provided by the present application, the raw materials of various non-metallic materials in the storage device 10 are transported to the heating device 30 through the feeding device 20, and the raw materials are heated to liquefaction by the heating device 30, so as to realize Uniform mixing of multiple materials, and then inject the liquefied raw materials into the mold cavity 41 corresponding to the shape of the hopper to be prepared to form a composite material hopper, which can realize the functional requirements of the hopper by utilizing the characteristics of various materials In order to avoid the problems that the steel hopper is too heavy and prone to rust, it is also possible to prepare a one-piece hopper, which not only avoids complicated processes such as welding, reduces the difficulty and time of preparation, but also improves the consistency of the hopper .

[0048] In an embodiment, the molding devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com