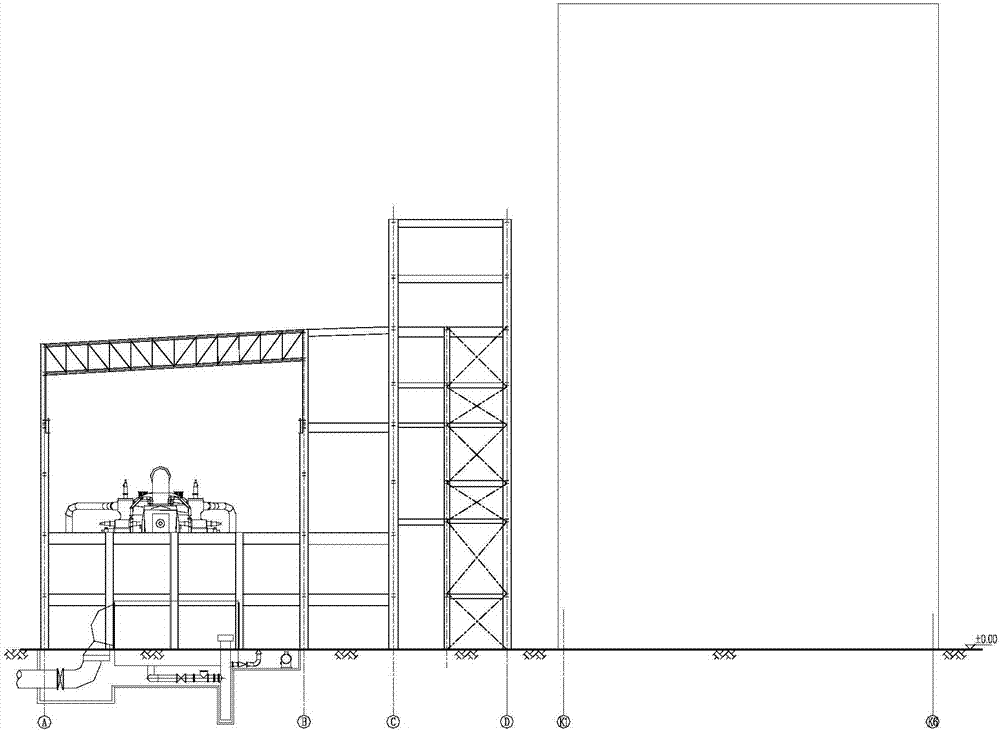

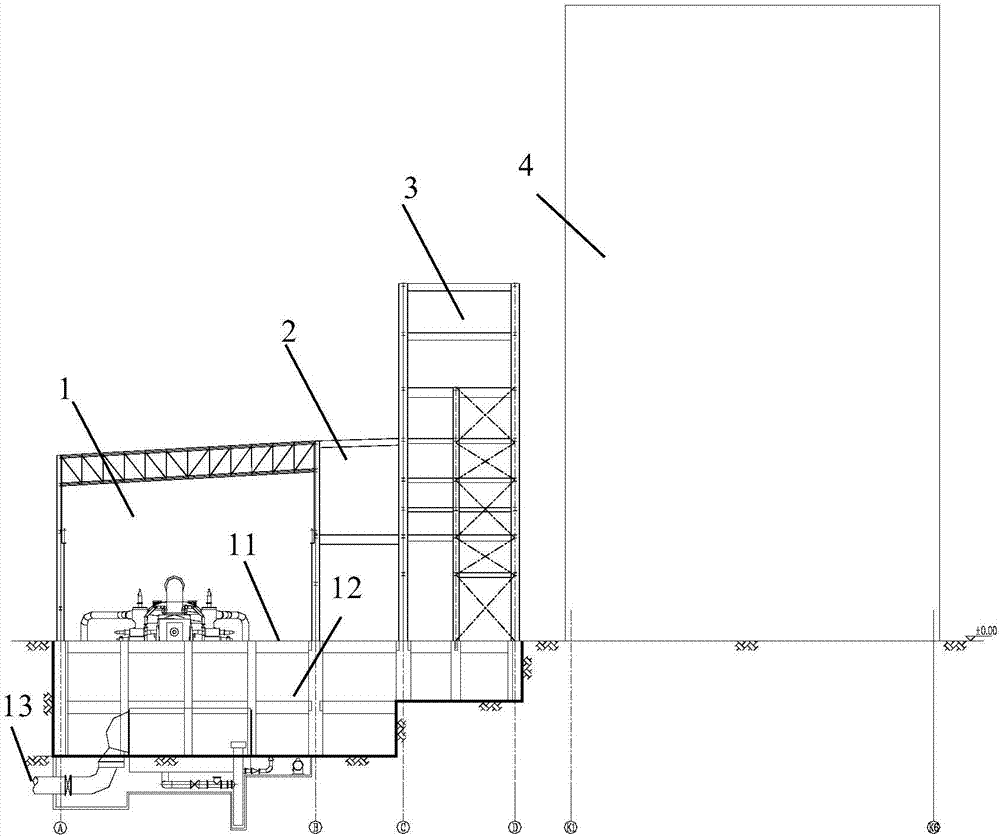

Main power house allocation structure of high-capacity thermal power station

A technology of thermal power generation and configuration structure, applied in the direction of industrial buildings, etc., can solve the problems of increasing the equipment construction site, increasing the complexity of the process system, increasing the investment in power plant construction, etc., achieving strong applicability and practicability, increasing reliability and Safety type, the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Explanation of terms:

[0037] Thermal power plant: A factory that converts heat energy generated by coal combustion into kinetic energy to produce electricity.

[0038] Large-capacity thermal power plant: a thermal power plant with a single generating capacity greater than or equal to 300MW.

[0039] Main powerhouse: The building used to support, enclose and install the main power generation equipment and its auxiliary equipment is the core building of the power plant. The main building of the thermal power plant consists of a turbine room, a deaerator room and a coal bunker room.

[0040] Boiler: It uses the heat energy released by coal combustion to heat water and generate specified parameters (temperature, pressure). It is one of the main equipment in thermal power plants.

[0041] Boiler frame: a structural support for supporting the boiler body and auxiliary equipment, which can be a steel structure support, or a reinforced concrete or other material structure s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com