Method for relieving atmosphere melamine circulated gas compressor runner impellor wall block-up

A melamine and circulating gas technology, applied in the direction of organic chemistry, etc., can solve the problems such as the reduction of the gas linear velocity at the inlet of the circulating gas compressor, the unbalanced operation of the impeller of the circulating gas compressor, and the reduction of the suction capacity of the circulating gas compressor, etc. The effect of depositing on the wall, improving the efficiency of production and operation, and increasing the degree of turbulent scouring

Inactive Publication Date: 2009-06-03

中国石油乌鲁木齐石油化工有限公司

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

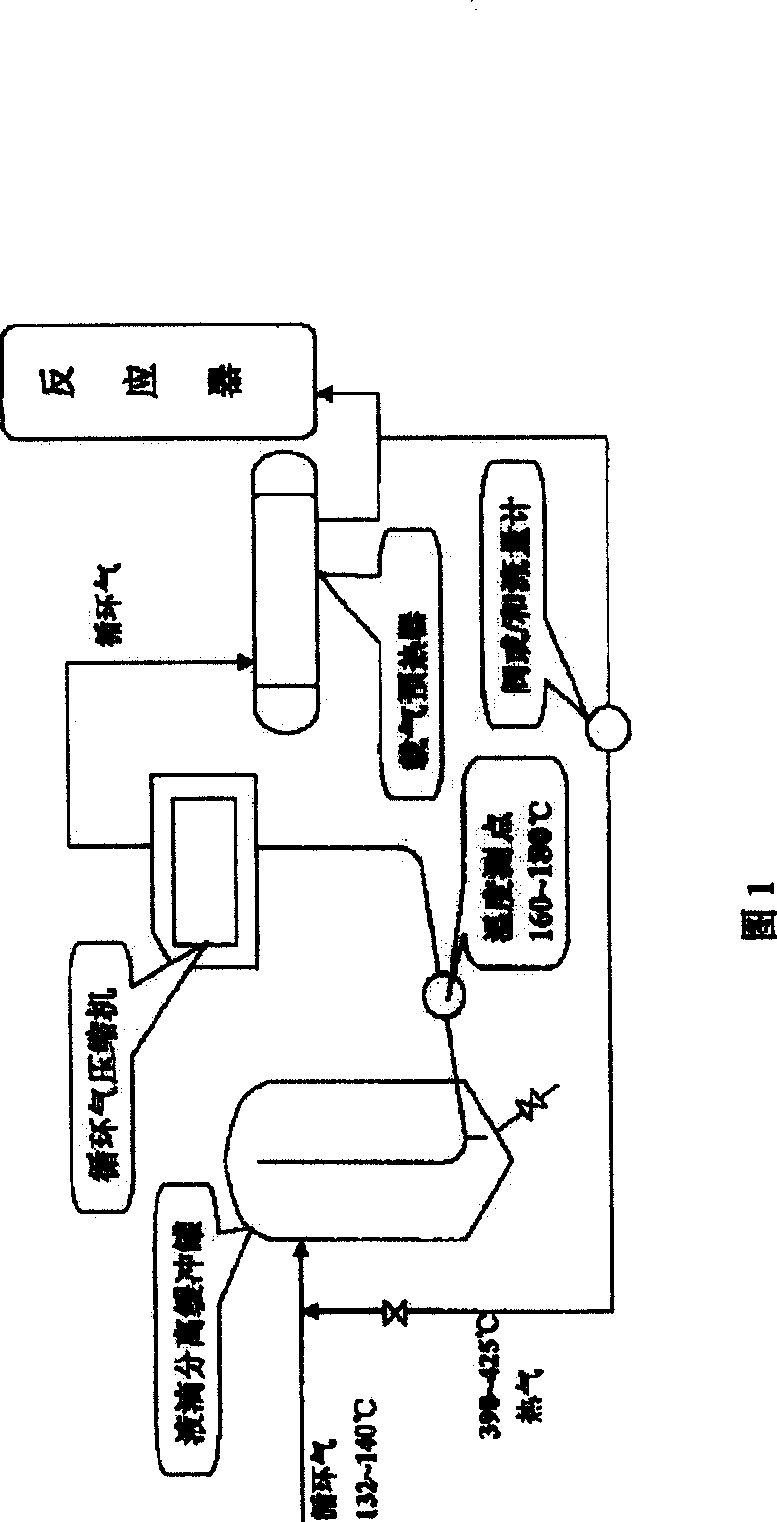

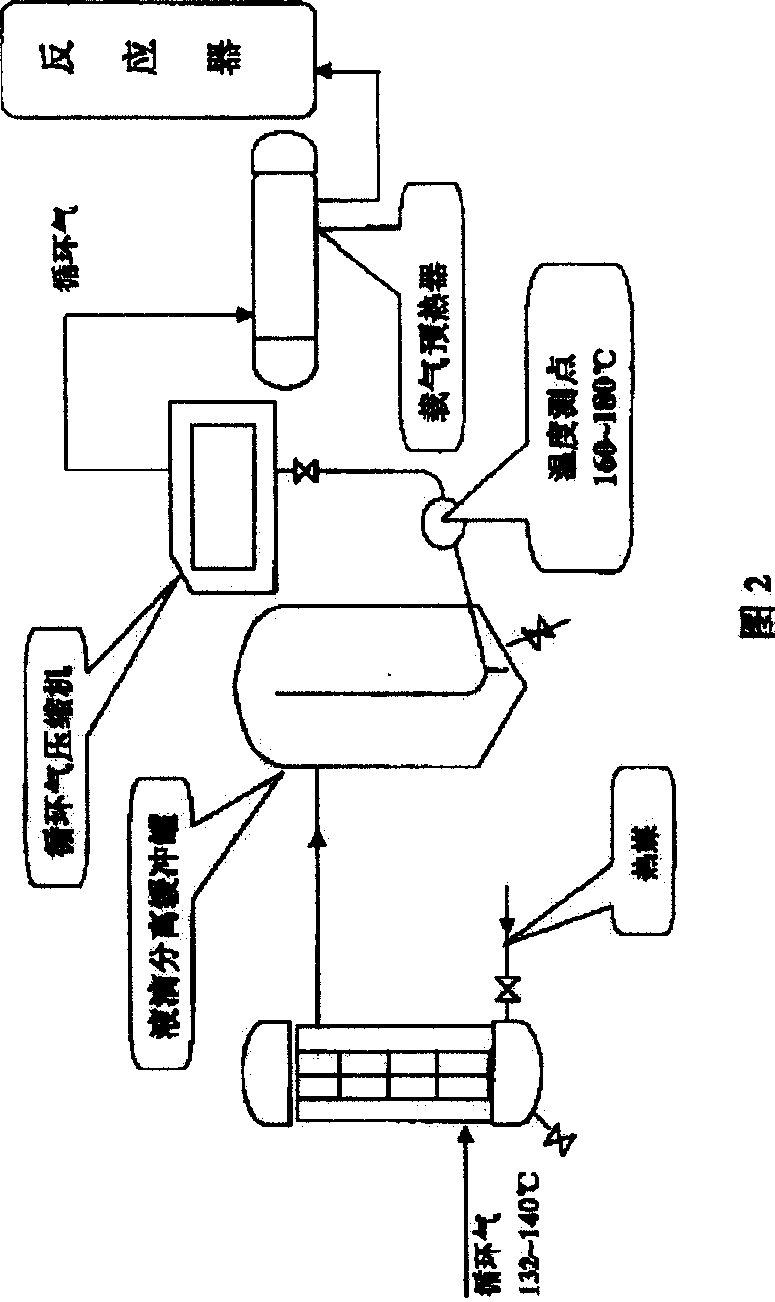

[0002] In the normal pressure melamine production method of the prior art, the inlet gas of the recycle gas compressor is the gas-liquid-solid three-phase mixture (called recycle gas) after the urine washing tower is washed and dedusted and the droplet separator is deliquored. The main part is ammonia, carbon dioxide mixed gas, followed by a small amount of liquid droplets (mainly urea droplets and a small amount of diuretic droplets) and a small amount of solid powder (containing traces of melamine and its high oligomer powder, catalyst powder grains, etc.), the temperature of urine and circulating gas is controlled by the temperature-adjusting water heat exchanger in the middle of the urine washing tower and the urine circulation spray washing volume of the urine washing tower. The normal temperature of the liquid and circulating gas is controlled within 132 degrees Celsius to 140 degrees Celsius, and the gas pressure at the inlet of the circulating gas compressor is controlled within the normal pressure range. During normal production and operation, the urea droplets, diuretic droplets, Melamine and its high and low polymer powders, and catalyst powders continue to crystallize and adhere to the flow channel between the inlet stages of the melamine recirculation gas compressor and the surface of the impeller, resulting in unbalanced operation of the impeller of the recirculation gas compressor, and frequent and unstable vibration alarms of the shaft. The longer the running time, the more crystallized and sticky, and the heavier it will be. On average, after 20 to 30 days of continuous operation, the shaft vibration will reach the alarm chain stop state. As the linear velocity of the gas decreases, the degree of fluid turbulence scour also decreases, which in turn increases the residence time of the fluid on the flow channel and impeller of the circulating air compressor, making it easier for the wall to deposit and block, forming a vicious cycle, and the shaft of the circulating air compressor vibrates As the deterioration intensifies, the pumping volume continues to decrease, so that the gas at the outlet of the circulating gas compressor enters the reactor to fluidize the catalyst (called high-temperature carrier gas) and the flow rate continues to decrease, which cannot meet the production and is forced to shut down, with an average of 20 days to 30 days. The circulating gas compressor needs to be disassembled and cleaned within a few days. The operating flexibility of the circulating gas compressor is small, the operating conditions are harsh, the continuous operation cycle is short, the start-up and shutdown are frequent, and the maintenance is frequent, so it cannot run safely and stably for a long period of time, which increases the production cost. Affect production and operation benefits. Therefore, the blockage of the flow channel between the inlet stages of the circulating gas compressor and the surface of the impeller is crystallized and adhered to the wall. The main bottleneck of safe and stable long-term full-load high-quality production of gas compressors

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0017] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0018] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The method of reducing plugging in circular gas compressor flow channel and impeller wall for normal pressure melamine producing process is to control the temperature of gas in the entrance of circular gas compressor at 160-180 deg.c. The said method can reduce plugging in circular gas compressor flow channel and impeller wall obviously, and ensure the stable running of the circular gas compressor in great intake amount, high linear speed and long stable production period.

Description

1. Technical field: [0001] The invention relates to the technical field of producing melamine by the normal pressure method, and relates to a method for slowing down the clogging of the flow channel impeller of the melamine circulating gas compressor by the normal pressure method. 2. Background technology: [0002] In the normal pressure melamine production method of the prior art, the inlet gas of the recycle gas compressor is the gas-liquid-solid three-phase mixture (called recycle gas) after the urine washing tower is washed and dedusted and the droplet separator is deliquored. The main part is ammonia, carbon dioxide mixed gas, followed by a small amount of liquid droplets (mainly urea droplets and a small amount of diuretic droplets) and a small amount of solid powder (containing traces of melamine and its high oligomer powder, catalyst powder grains, etc.), the temperature of urine and circulating gas is controlled by the temperature-adjusting water heat exchanger in t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C07D251/60

Inventor 姚维斌

Owner 中国石油乌鲁木齐石油化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com