Process for pre-assembling bow thrustor on ship body section

A hull and pre-installation technology, applied in the field of ship construction, can solve the problems of delaying the hull manufacturing period, economic losses of manufacturers, wasting time and manpower, etc., and achieve the goal of reducing the workload of turning over, shortening the construction period, and reducing the time for positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings, based on a pre-installation process of a bow thruster of a container ship on a hull segment.

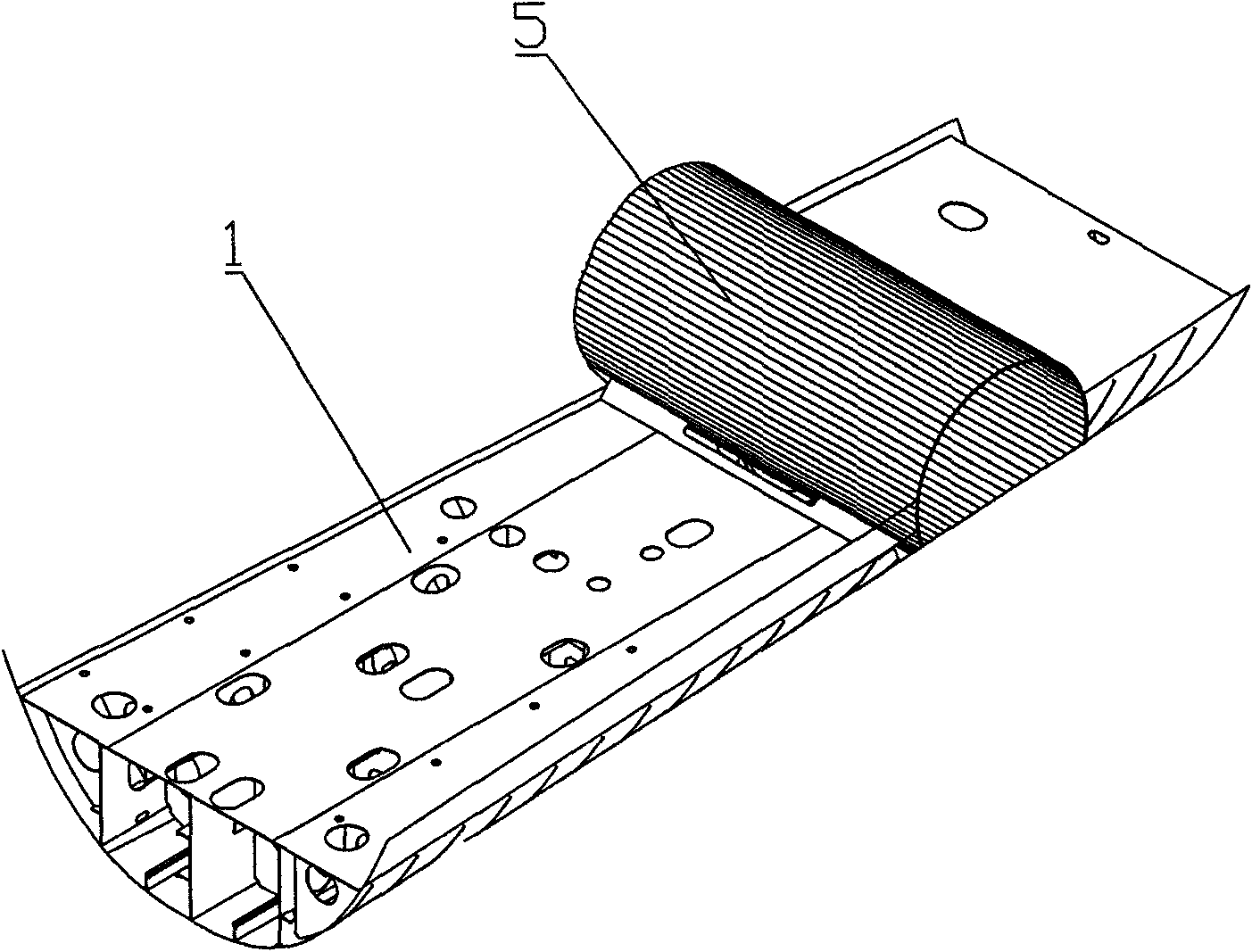

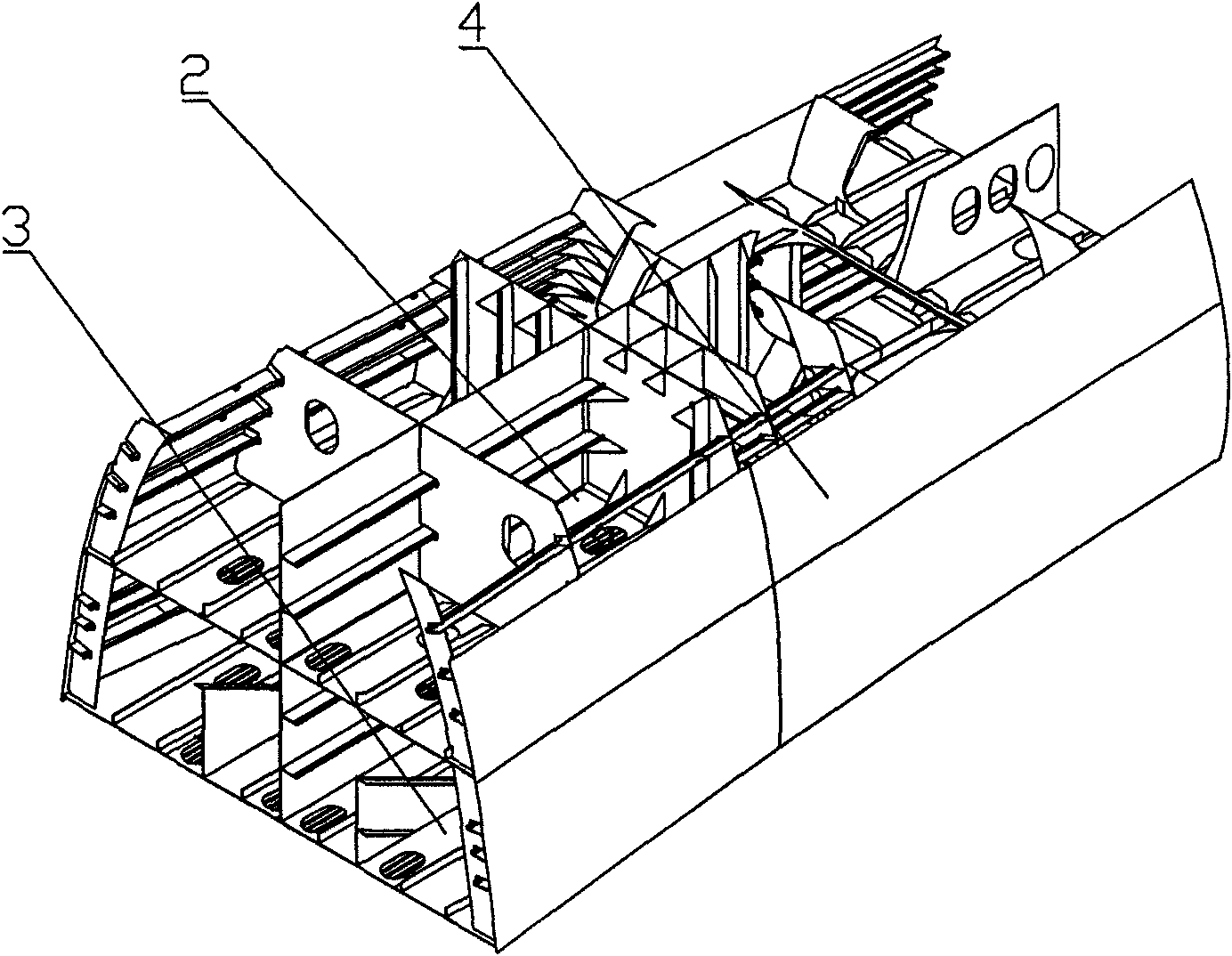

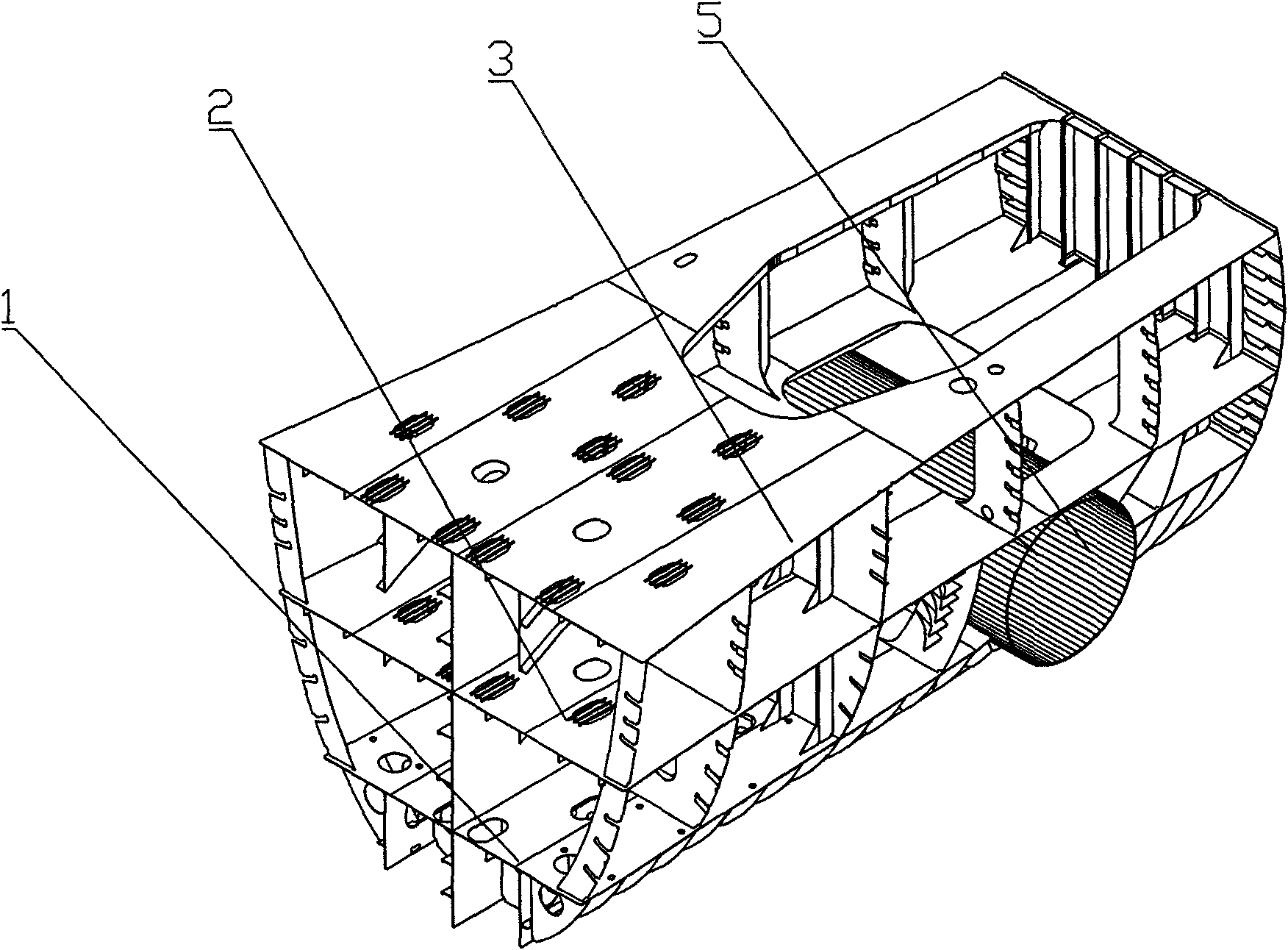

[0019] Such as figure 1 , 2 As shown, the container hull section is divided into a lower subsection 1, a middle subsection 2 and an upper subsection 3 according to different working platforms, wherein the lower subsection 1 is used for installing the bow thruster 5.

[0020] During the pre-installation process of the hull section of the bow thruster of the container ship, the lower subsection 1, the middle subsection 2, and the upper subsection 3 of the hull section are first manufactured inversely based on different platforms. Scattered and attached to the outer plate, the so-called anti-state here is exactly the opposite of the state when the hull is running normally. Wherein the lower subsection 1 can change some parts into bulk parts when carrying out reverse state manu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com