Socket-and-spigot joint structure of prefabricated pier column and bearing platform and construction method

A socket-type, prefabricated pier technology, which is applied to bridges, bridge parts, bridge construction, etc., can solve the problems of increased engineering volume of caps and pier columns, increased installation difficulty, and on-site positioning difficulties, so as to reduce project cost, The effect of reducing the workload of cast-in-place and high embedding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

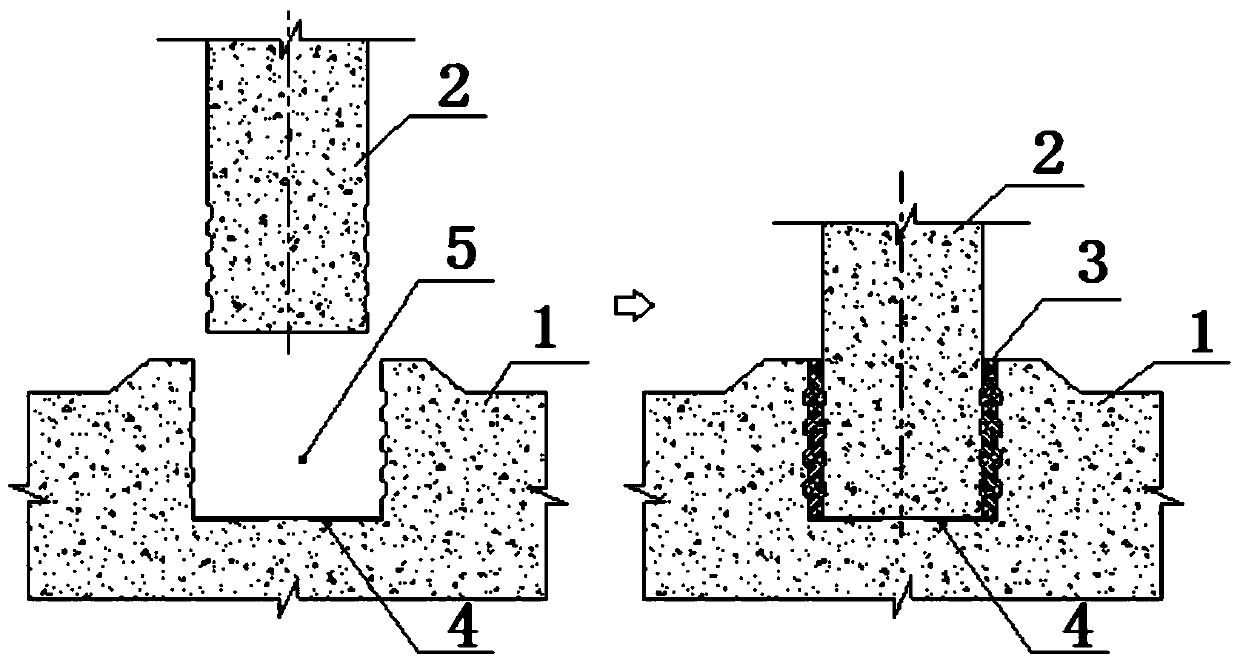

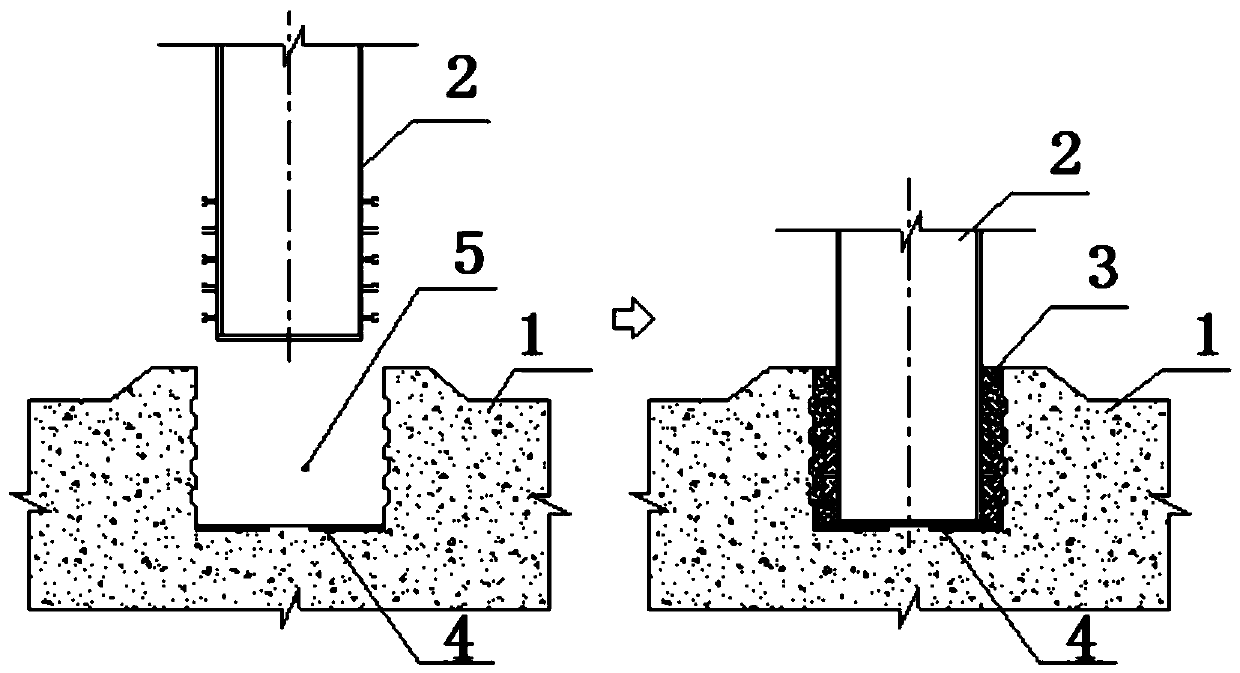

[0021] As shown in the figure, the socket connection structure and construction method of the prefabricated pier column and cap platform using high-strength steel fiber reinforced concrete caulking is characterized in that a bearing slot is reserved at the position corresponding to the pier column on the top of the cap platform, and the prefabricated pier column is hoisted Insert it into the socket, and pour high-strength steel fiber concrete caulking into the gap between the periphery of the pier column and the wall of the socket to achieve a firm connection. The purpose of simple structure, high embedding efficiency, safe and reliable connection, convenient and fast construction and economical cost is achieved.

[0022] See details figure 1 , figure 2 , the construction cap 1, the bearing slot 5 of the pier column 2 is reserved. Lay the cement mortar se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com