Spiral steel, application product of same, and method for manufacturing spiral steel

A manufacturing method, the technology of spiral steel, applied in the field of spiral steel, can solve the problems of flat steel difficult to process, longitudinal bending, deformation, etc., and achieve the effect of shortening the pitch and improving the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Hereinafter, the spiral steel of the present invention, its application products, and the manufacturing method of the spiral steel will be described in detail.

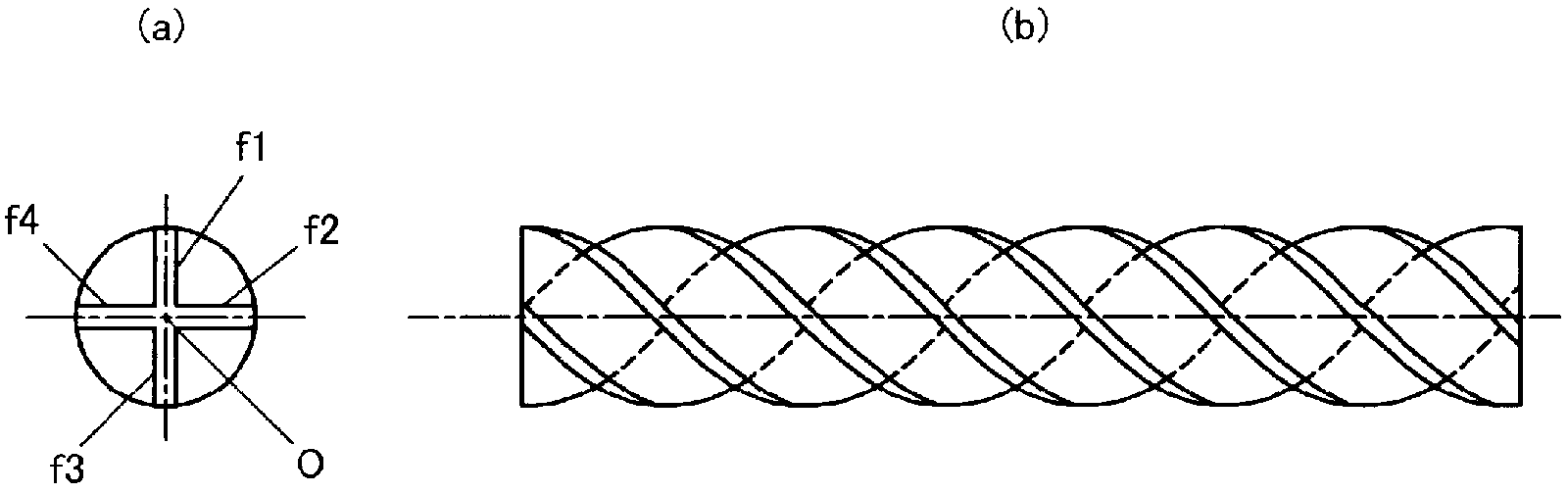

[0066] figure 2 It is a figure explaining the helical steel of this invention.

[0067] The helical steel of the present invention is formed by twisting the steel material along the central axis with an axis parallel to the long axis direction of the steel material as the central axis O, and the steel material has at least three or more long-side members (f1 to f4) relative to each other. The central axis O is radially arranged.

[0068] figure 2 (a) shows a cross-sectional view perpendicular to the long axis direction of the helical steel, figure 2 (b) shows the side view of the helical steel.

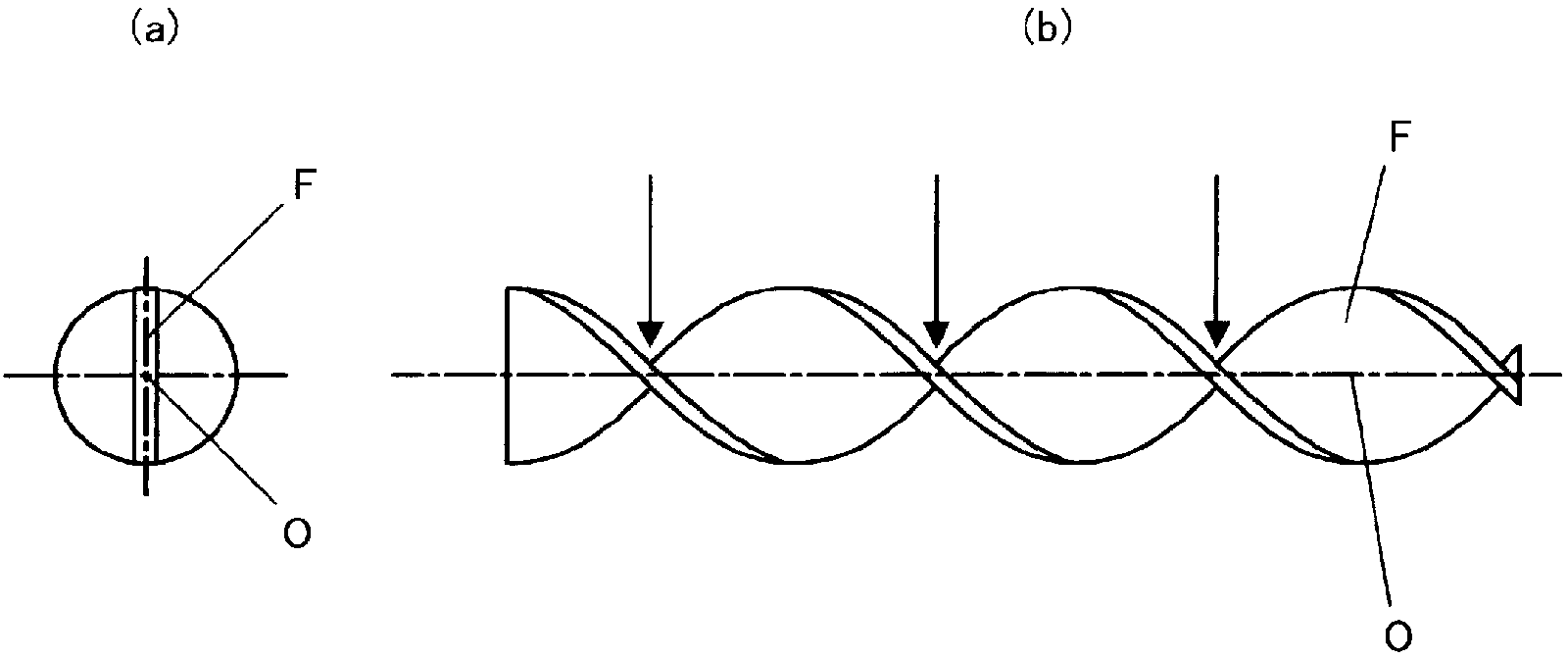

[0069] figure 1 twisted flat steel with figure 2 Compared with the spiral steel, the difference between the two is clear, in particular, there is no spiral steel figure 1 The mechanical strength of the porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com