Molding machine for producing high-strength wood particles

A technology of wood pellets and molding machines, which is applied in the direction of raw material extrusion and granulation, which can solve the problems of easy pulverization, inconvenient replacement of molds, unevenness of pressing rollers, etc., to achieve increased particle strength, increased extrusion strength, and improved The effect of granulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

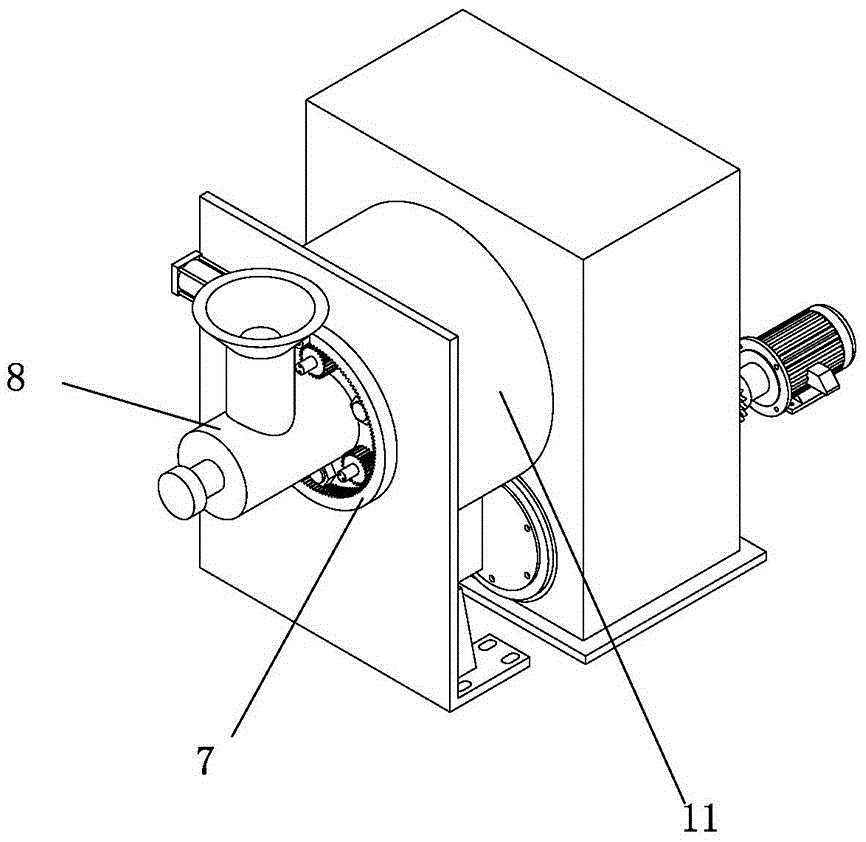

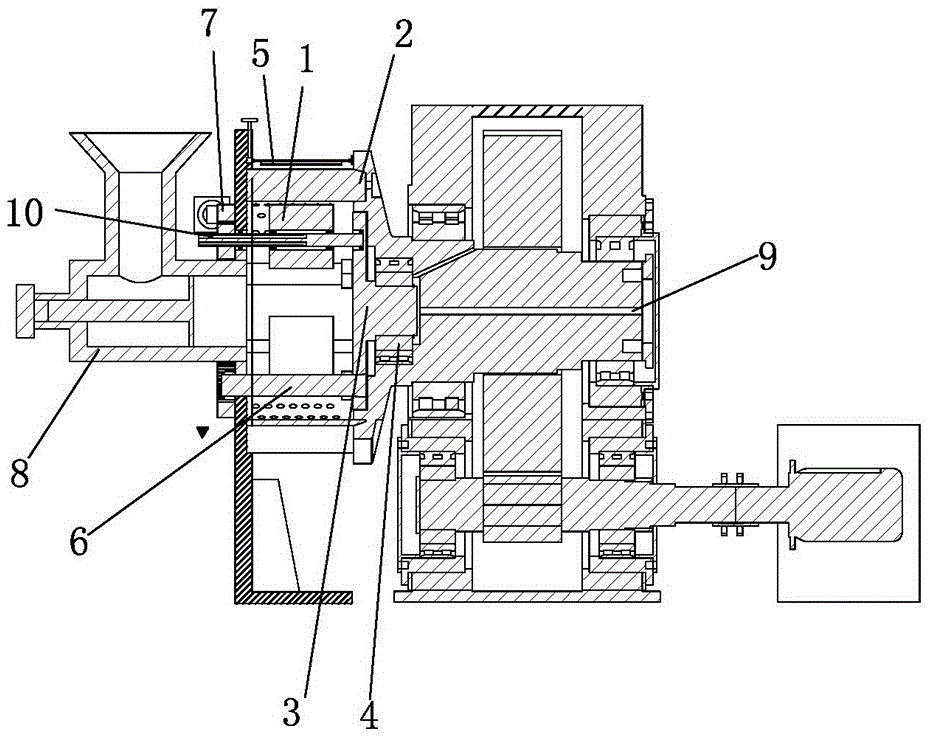

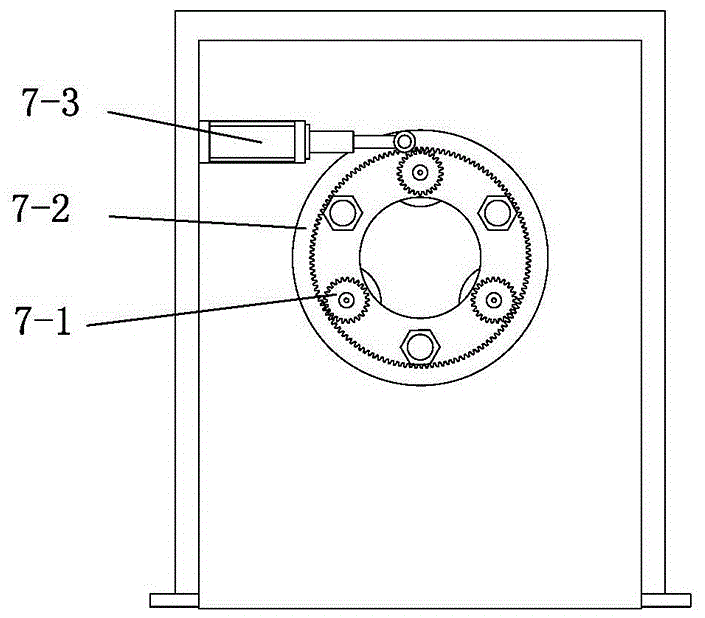

[0040] Embodiment 1: as figure 1 with figure 2 As shown, a molding machine for producing high-strength wood pellets includes a press wheel assembly 1, a mold assembly 2, a conversion joint 3, a main bearing 4, a moving cutting assembly 5, a fastening mechanism 6, an adjustment mechanism 7, and a feeding device 8 , The first cooling channel 9, the second cooling channel 10, the outer cover 11 and the clamping part 12;.

[0041] Such as Figure 5 As shown, the mold assembly 2 includes a main shaft 2-1 and an annular mold 2-2; one end of the annular mold 2-2 is embedded and fixed on the main shaft 2-1 through a clamping part 12, and the main shaft 2-1 and the annular mold 2-2 is kept concentric, and the main shaft 2-1 is provided with a guide surface 2-1-2 for its installation at the matching installation position with the ring mold 2-2; the ring mold 2-2 has a mold cavity , there are a certain number of biomass fuel particle extrusion ports 2-2-1 on the ring surface, and at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com