Extruding machine facilitating uniform extrusion of cables

An extruder and uniform technology, applied in the manufacture of cables/conductors, insulation of conductors/cables, circuits, etc., can solve the problems of poor cable quality, uniform mixing of ingredients, breakage, etc., to reduce time waste and extrude uniformly , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The standard parts used in the present invention can be purchased from the market, and the special-shaped parts can be customized according to the instructions and the accompanying drawings. The specific connection methods of each part adopt mature bolts, rivets, welding in the prior art , pasting and other conventional means, no longer described in detail here.

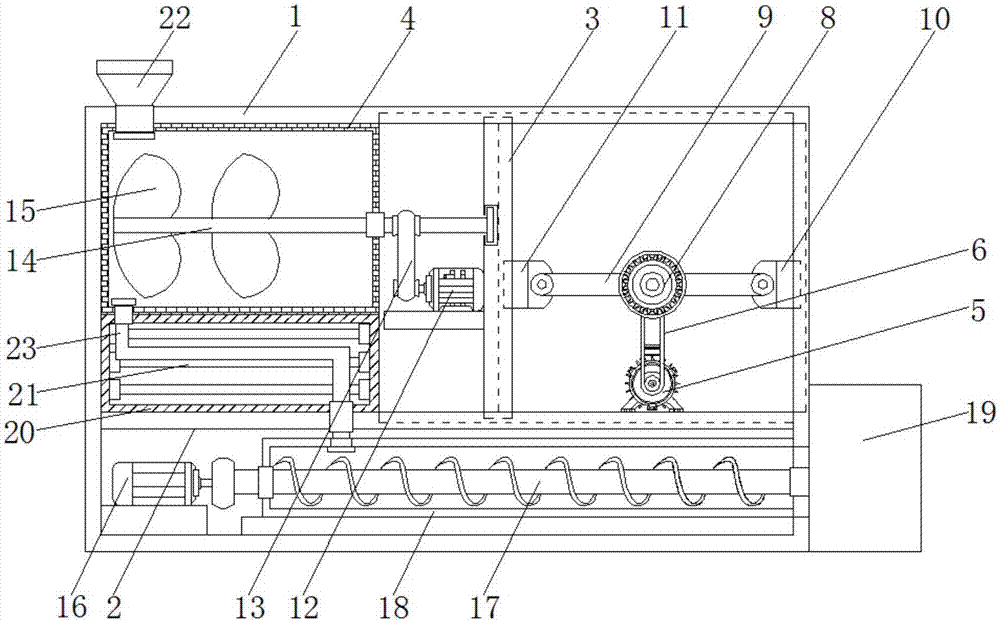

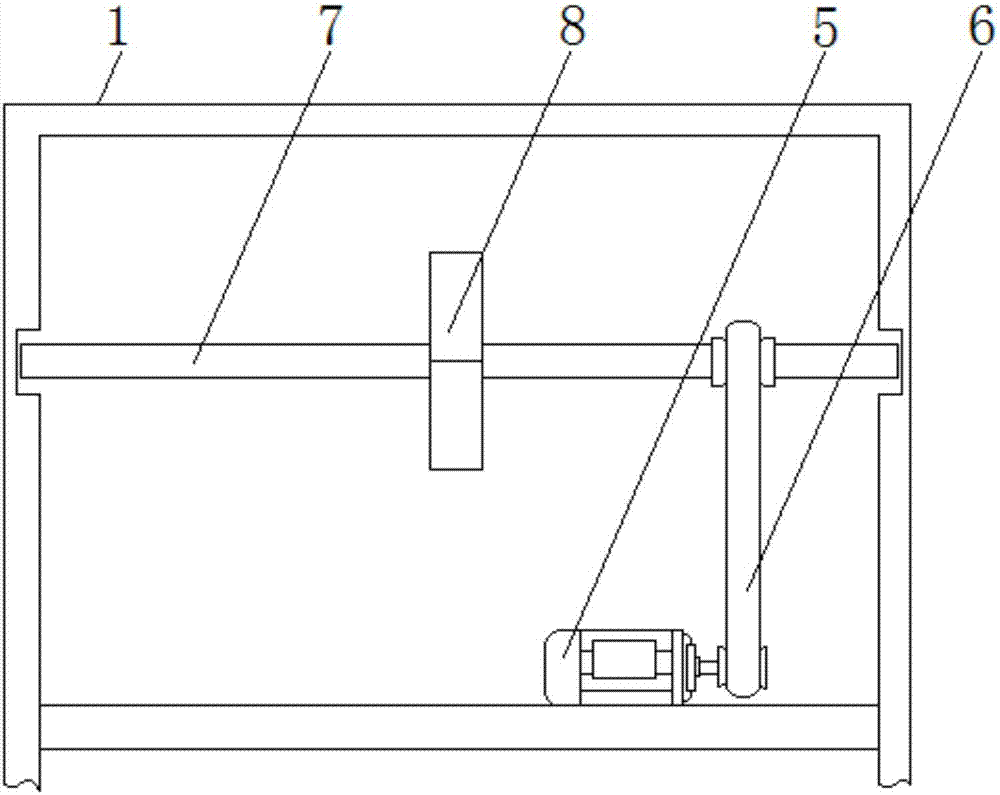

[0015] refer to Figure 1-2 A specific embodiment of the present invention includes a box body 1, a bottom plate 2 is fixedly connected between the two sides of the inner wall of the box body 1, a support plate 3 is slidably connected between the top of the bottom plate 2 and the top of the inner wall of the box body 1, and the box body 1 A stirring box 4 is fixedly connected between both sides of the inner wall, a preheating box 20 is fixedly connected between the top of the bottom plate 2 and the bottom of the stirring box 4, and a heating pipe 21 is arranged inside the preheating box 20 for preheating A fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com