Electric heating tube extrusion device

An extrusion device and electric heating tube technology, which is applied in heat exchange equipment, metal processing equipment, forming tools, etc., can solve the problems of uneven extrusion of electric heating tubes and non-continuous extrusion process, and achieve convenient handling and replacement application scenarios Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

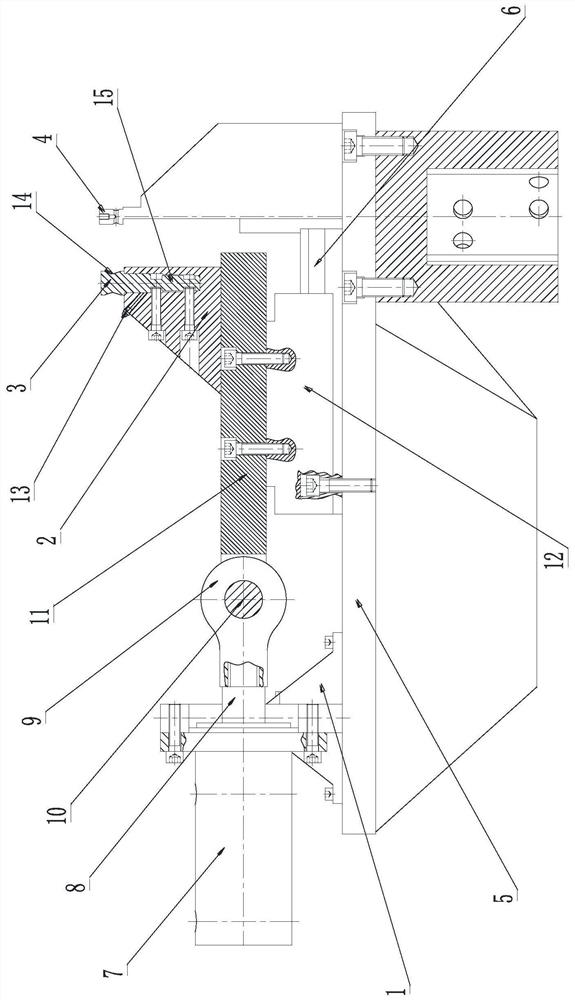

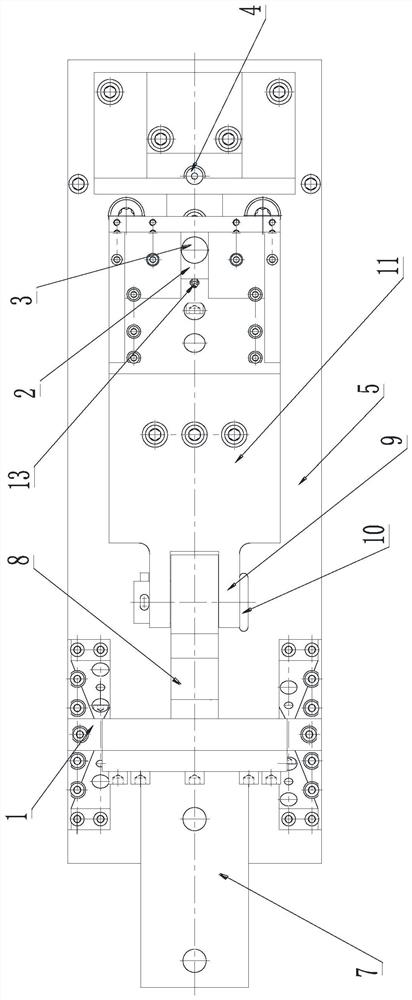

[0022] see Figure 1-2 , an electric heating tube extruding device, comprising a relatively fixed linear motion driving part and a fixed seat 1, the output end of the linear motion driving part faces the fixed seat 1, and the output end of the linear motion driving part is provided with Extruding part, the top of the extruding part is rotated by a vertical rotating shaft 15 to be provided with an extruding wheel 3 , and the top end of the fixed base 1 is provided with a supporting member 4 cooperating with the extruding wheel 3 .

[0023] In this embodiment, when working, the electric heating tube is placed between the extrusion wheel 3 and the support member 4, and then the linear motion driving part is started, so that the linear motion driving part drives the extrusion part to approach the fixed seat 1 until the electric heating tube Deformation occurs to a preset value, and then the linear motion drive part is stopped, so that the position between the extrusion part and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com